Preparation method for low-acetaldehyde beer

A low-acetaldehyde and beer technology, applied in the field of beer brewing, can solve problems such as acetaldehyde residues, increase the number of yeast cells, improve suspension performance, and avoid flocculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

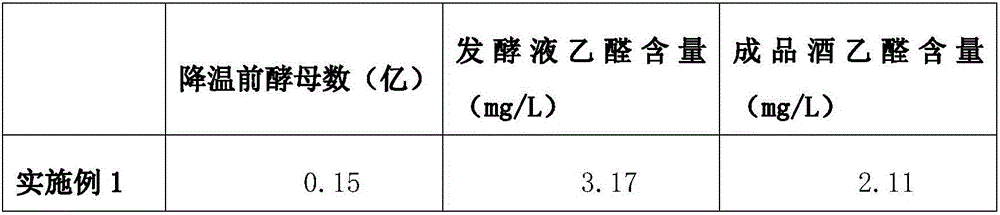

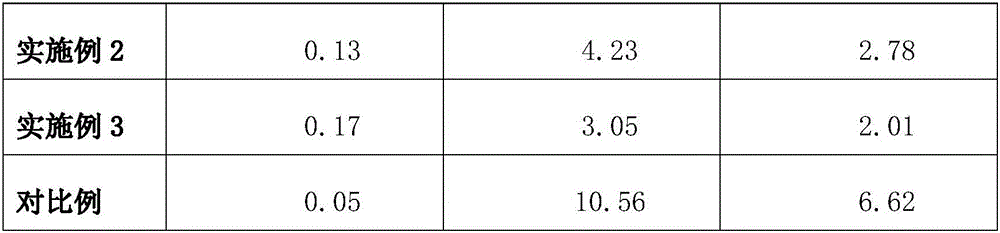

Examples

Embodiment 1

[0026] Step 1: Take 3000kg of rice, 1600kg of Australian wheat, 2200kg of added wheat, 1300kg of national wheat, and 720kg of wheat malt, of which the PYF value of Australian wheat is 0.85, the PYF value of added wheat is 1.12, the PYF value of national wheat is 0.56, the PYF value of wheat malt is 1.15, and the mixed malt PYF value 0.92;

[0027] Step 2: Pulverize the rice with a pulverizer to obtain ground rice, which is set aside;

[0028] Step 3: Pulverize Australian wheat, added wheat, national wheat, and wheat malt with a grinder to obtain ground malt for later use;

[0029] Step 4: Mix the crushed rice with 105 HL of brewing water, then raise the temperature from 65°C to 95°C and keep it warm for 40 minutes to obtain rice mash;

[0030] Step 5: Mix malt powder with 190 HL brewing water and keep it warm at 50°C for 20 minutes, pump the rice mash and heat it up to 65°C and keep it warm for 8 minutes, heat it up to 72°C and keep it for 20 minutes, heat it up to 76°C and s...

Embodiment 2

[0035] Step 1: Take 3500kg of rice, 1530kg of Australian wheat, 1760kg of added wheat, 1240kg of national wheat, and 790kg of wheat malt, of which the PYF value of Australian wheat is 0.75, the PYF value of added wheat is 0.90, the PYF value of national wheat is 0.61, and the PYF value of wheat malt is 1.02. PYF value 0.80;

[0036] Step 2: Pulverize the rice with a pulverizer to obtain ground rice, which is set aside;

[0037] Step 3: Pulverize Australian wheat, added wheat, national wheat, and wheat malt with a grinder to obtain ground malt for later use;

[0038] Step 4: Mix the crushed rice with 105 HL of brewing water, then raise the temperature from 65°C to 95°C and keep it warm for 40 minutes to obtain rice mash;

[0039] Step 5: Mix malt powder with 190 HL brewing water, heat it at 51°C for 23 minutes, pump the rice mash and heat it up to 66°C, heat it for 10 minutes, heat it up to 72°C, heat it for 23 minutes, heat it up to 76°C and send it to filter after passing th...

Embodiment 3

[0044] Step 1: Take 2650kg of rice, 1760kg of Australian wheat, 2600kg of added wheat, 1300kg of national wheat, and 500kg of wheat malt, of which the PYF value of Australian wheat is 0.95, the PYF value of added wheat is 1.25, the PYF value of national wheat is 0.65, and the PYF value of wheat malt is 1.21. The PYF value is 1.03; step 2: the rice is pulverized by a pulverizer to obtain rice pulverization, which is set aside;

[0045] Step 3: Pulverize Australian wheat, added wheat, national wheat, and wheat malt with a grinder to obtain ground malt for later use;

[0046] Step 4: Mix the crushed rice with 105 HL of brewing water, then raise the temperature from 65°C to 95°C and keep it warm for 40 minutes to obtain rice mash;

[0047]Step 5: Mix malt powder with 190 HL brewing water and keep it warm at 52°C for 25 minutes. Pump the rice mash and heat it up to 67°C and keep it warm for 10 minutes. Heat it up to 72°C and keep it for 25 minutes. After passing the iodine test, he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com