Crankshaft oil channel structure and crankshaft and compressor comprising same

A crankshaft and oil circuit technology, which is applied in the field of compressors, can solve the problems of large throttling loss of bearings, and achieve the effects of reducing power loss, reducing pressure, and reducing throttling loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

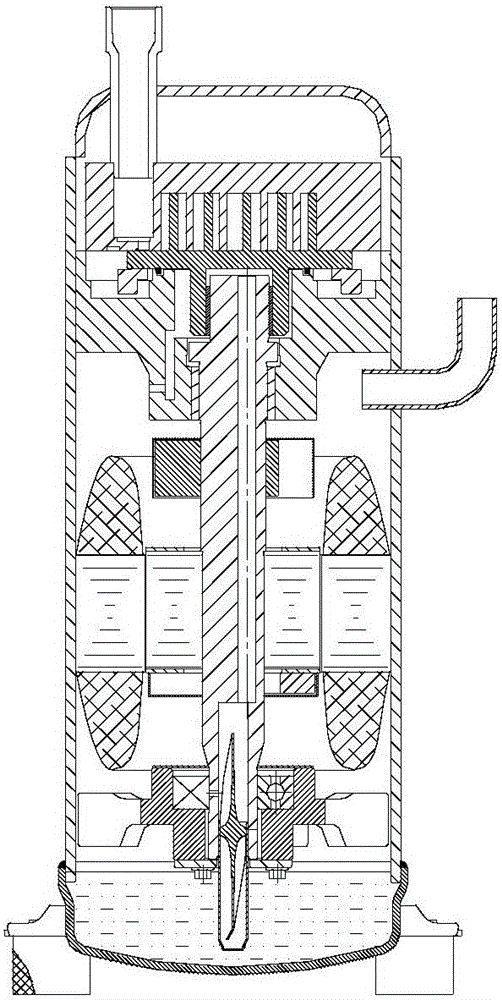

[0073] Such as figure 1 As shown, during the operation of the compressor, the oil circuit system in the traditional scroll compressor is that the oil in the oil sump at the bottom of the compressor enters the internal oil supply hole of the crankshaft through the oil suction pipe and the oil guide plate, and the oil supplied by the crankshaft The hole has an eccentric structure, which can generate centrifugal force, so that the oil in the oil supply hole can smoothly rise to the head of the crankshaft. After the oil passes through the axial oil outlet hole, it lubricates the moving disc bearing, flows into the back pressure oil pool, and then passes through the oil return pipe to release the oil. Return to the oil pool at the bottom of the compressor to form an oil circuit cycle.

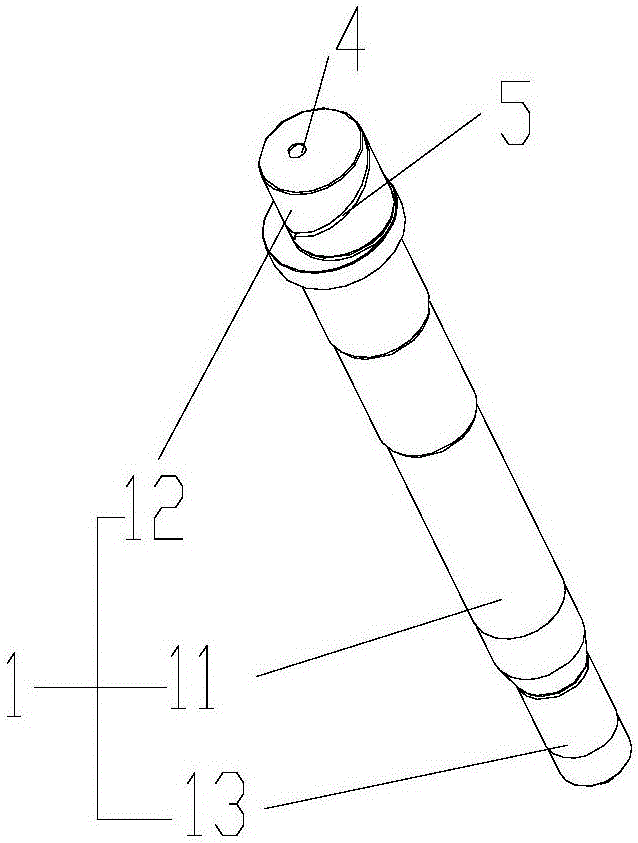

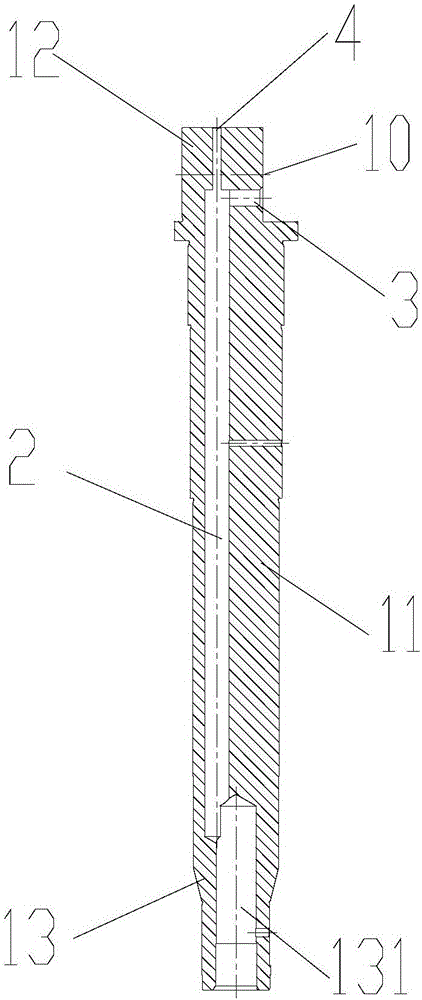

[0074] In the crankshaft oil circuit structure of the scroll compressor of the present invention, the oil passing through the oil hole 2 rises to the crankshaft head 12, and the oil circuit at the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com