Mining MEMS anemometer electric insulation self-cleaning packaging method

An encapsulation method and self-cleaning technology, applied in measurement devices, fluid velocity measurement, velocity/acceleration/impact measurement, etc., to achieve the effects of improving hydrophobicity, high insulation, and reducing surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

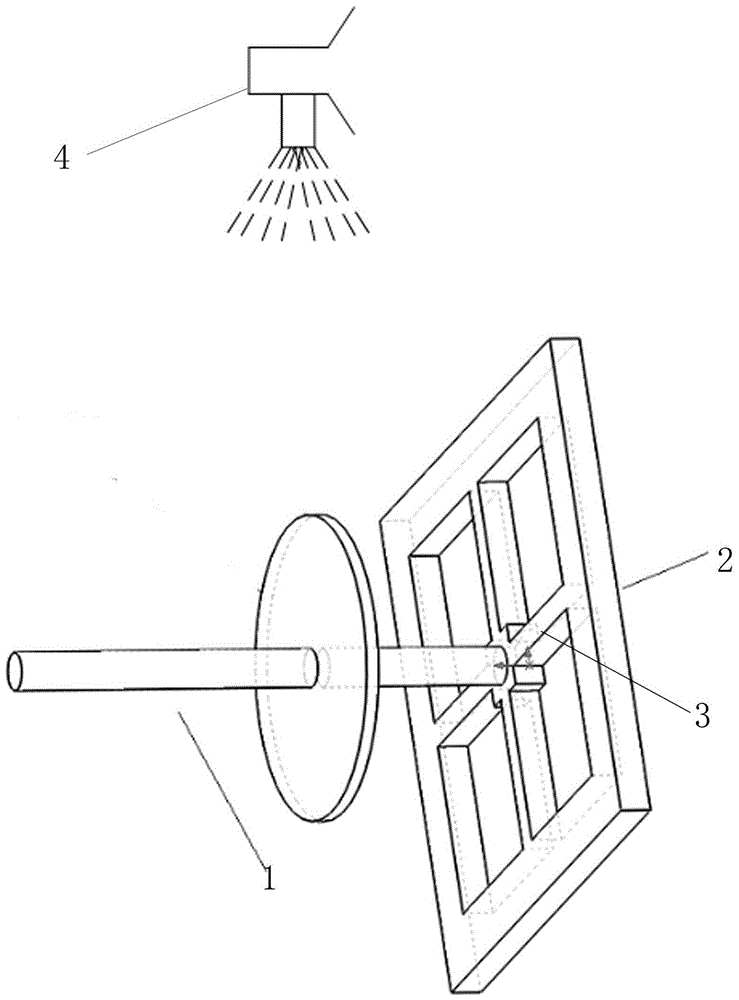

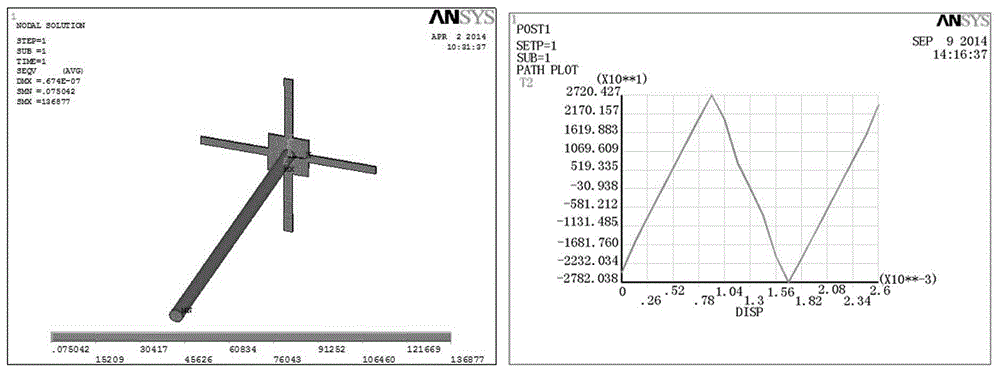

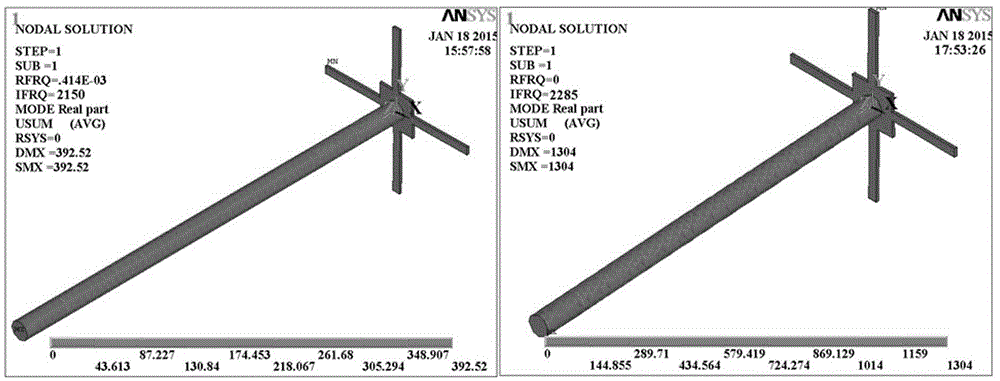

[0024] A mining MEMS anemometer electric insulation self-cleaning packaging method, comprising the following steps: (a) Parylene film deposition: put the vector anemometer into the film deposition system, add 3.2 grams of parylene particles to the trough of the film deposition system , turn on the parylene film deposition system, and after 2 hours at -100°C, a dense parylene film of 2 microns is deposited on the surface of the vector anemometer (the instrument required for this step is produced by SCS, model is PDS2010); (b) use ICP etching machine to process Parylene film, and use SF 6 For plasma treatment, the settings of the ICP etching machine are as follows: the chamber pressure is set to 30mT (1mT is 0.133Pa, 30mT is 3.99Pa, about 0.00004 atmospheres), the RF power of the upper and lower electrodes is 700w and 45w respectively, SF 6 The flow rate is 90sccm, and the etching can be completed after 420s at a temperature of 20°C. At this time, a highly hydrophobic surface is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com