Cichorium intybus inulin extracting method

A technology of chicory and inulin, which is applied in the field of producing inulin from chicory, which can solve the problems of low degree of continuous automatic production, high production cost, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

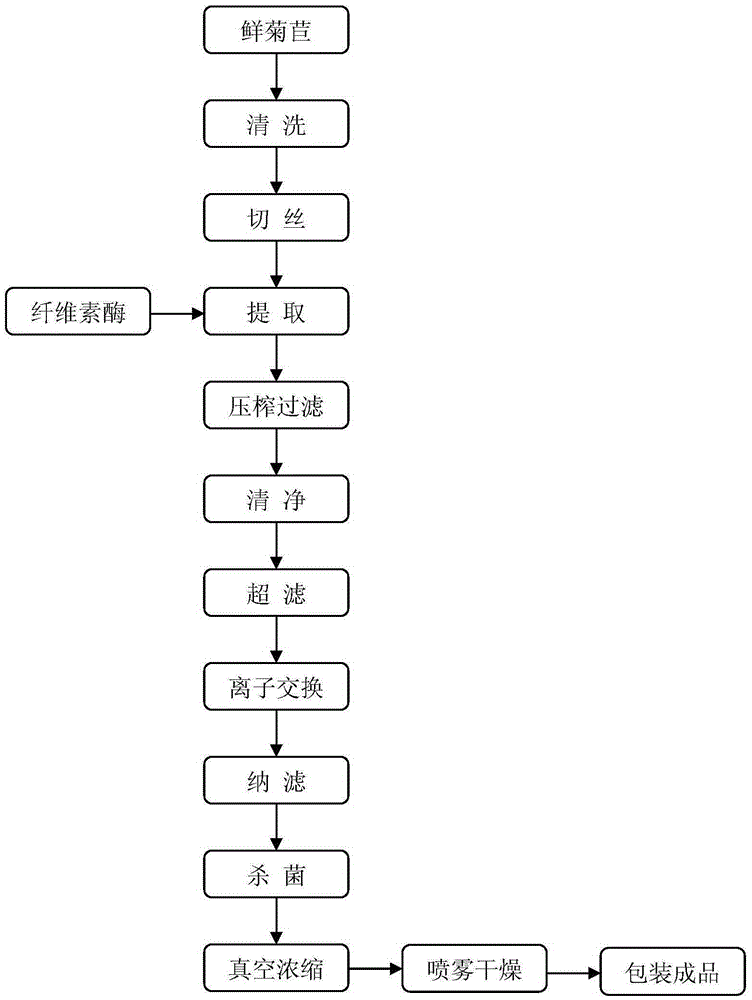

Method used

Image

Examples

Embodiment 1

[0016] Example 1 Weigh 5 tons of fresh chicory, wash and shred it, and transport it to a 30m 3 In the extraction tank, adjust the pH to 5.8-6.5, add 0.08 tons of cellulase, extract at 60°C for 3.0 hours, filter to remove the filter residue, and obtain a crude inulin extract. Under the conditions of temperature 35°C and pressure 1.5MPa, the feed liquid passes through a 0.5 μm ultrafiltration membrane to remove impurities such as ions and low-molecular organic matter, and then transfers it to a sterilizing tank at 95°C for pasteurization for 30 minutes to make the bacteria in the feed liquid Enzyme activity denatures, protein coagulates, cools to room temperature, and obtains a solution rich in inulin. Add 2.5% activated carbon to the tank, decolorize at 50°C for 30 minutes, filter to remove residual pigment; transfer the filtrate to a lime milk storage tank, add calcium hydroxide to adjust the pH to 10.0, treat at 80°C for 35 minutes, and filter to remove impurities; Pass ...

Embodiment 2

[0017] Example 2 Weigh 5 tons of fresh chicory, wash and shred it, and transport it to a 40m 3 In the extraction tank, adjust the pH to 5.8-6.5, add 0.12 tons of cellulase, extract at 60°C for 3.0 hours, filter to remove the filter residue, and obtain a crude inulin extract. Under the conditions of temperature 35°C and pressure 1.5MPa, the feed liquid passes through a 0.5 μm ultrafiltration membrane to remove impurities such as ions and low-molecular organic matter, and then transfers it to a sterilizing tank at 95°C for pasteurization for 30 minutes to make the bacteria in the feed liquid Enzyme activity denatures, protein coagulates, cools to room temperature, and obtains a solution rich in inulin. Add 2.5% activated carbon to the tank, decolorize at 50°C for 30 minutes, filter to remove residual pigment; transfer the filtrate to a lime milk storage tank, add calcium hydroxide to adjust the pH to 10.0, treat at 80°C for 35 minutes, and filter to remove other impurities; ...

Embodiment 3

[0018] Example 3 Weigh 5 tons of fresh chicory, wash and shred it, and transport it to a 50m 3 In the extraction tank, adjust the pH to 5.8-6.5, add 0.16 tons of cellulase, extract at 60°C for 3.0 hours, filter to remove the filter residue, and obtain a crude inulin extract. Under the conditions of temperature 35°C and pressure 1.5MPa, the feed liquid passes through a 0.5 μm ultrafiltration membrane to remove impurities such as ions and low-molecular organic matter, and then transfers it to a sterilizing tank at 95°C for pasteurization for 30 minutes to make the bacteria in the feed liquid Enzyme activity denatures, protein coagulates, cools to room temperature, and obtains a solution rich in inulin. Add 2.5% activated carbon to the tank, decolorize at 50°C for 30 minutes, filter to remove residual pigment; transfer the filtrate to a lime milk storage tank, add calcium hydroxide to adjust the pH to 10.0, treat at 80°C for 35 minutes, and filter to remove impurities; Pass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com