Preparation method of acidically-decomposable high-temperature-resistant gel blocking agent

A plugging agent and high temperature resistance technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as difficult to remove plugs, limited application range, and insufficient high temperature resistance effect, and achieve high temperature resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

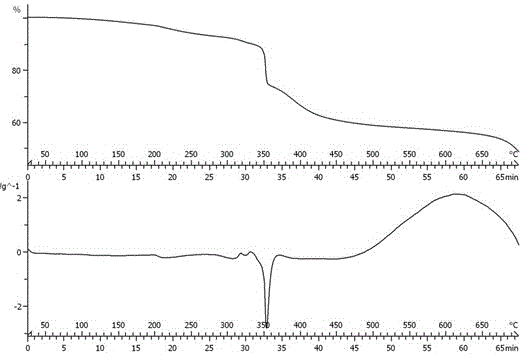

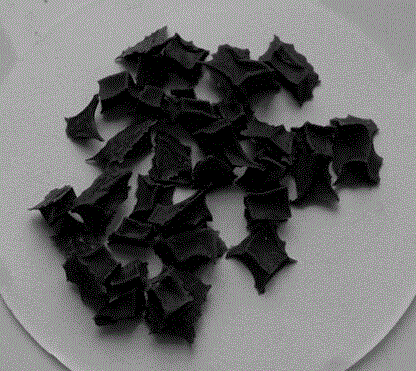

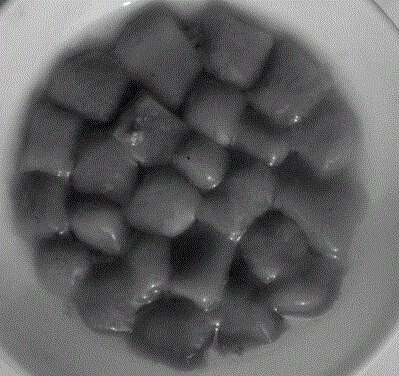

Image

Examples

Embodiment 1

[0050] The invention discloses a preparation method of an acidification-decomposable anti-high temperature gel plugging agent, which mainly includes two parts, one is to modify bentonite; the other is to prepare the gel plugging agent.

[0051] The modification method of bentonite is as follows:

[0052] Weigh 1 to 3 parts by weight of sodium hydroxide, 2 to 5 parts by weight of NaOH 2 CO 3 , and the balance is water, which is added to the reaction vessel, and the temperature is raised to 80°C to 90°C under stirring. Weigh 7-12 parts by weight of bentonite and slowly add it into the reaction vessel, keep stirring during the adding process, raise the temperature to 100°C after the addition is completed, and react at 100°C for 4 hours. After the reaction, cool to room temperature, wash and dry the reactant to obtain modified bentonite.

[0053] The preparation method of gel plugging agent is as follows:

[0054] (1) The modified bentonite is formulated into a modified benton...

Embodiment 2

[0078] Change the holding time after raising the temperature to 100°C in the bentonite modification reaction to 3.5 hours; change the water bath heating time in the gel sealing agent preparation reaction to 4.5 hours, and change the drying time to 8.5 hours. Other conditions are the same as the implementation example 1.

Embodiment 3

[0080] Change the holding time after raising the temperature to 100°C in the bentonite modification reaction to 4.5 hours; change the water bath heating time in the gel sealing agent preparation reaction to 5.5 hours, and change the drying time to 9.5 hours. Other conditions are the same as the implementation example 1.

[0081] After comparing the gel plugging agents prepared in the above three examples, it is concluded that the three have the advantages of high temperature resistance, high toughness, and easy acid decomposition compared with other existing gel plugging agents. , and the performance of the gel plugging agent prepared in Example 1 is more prominent among the three.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com