High-temperature-resistant organic silicon-modified epoxy resin and method for preparing same

A technology of epoxy resin and silicone, which is applied in the field of high-temperature-resistant silicone-modified epoxy resin and its preparation, can solve the problems of poor compatibility and long reaction time, and achieve good storage stability, fast response, good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

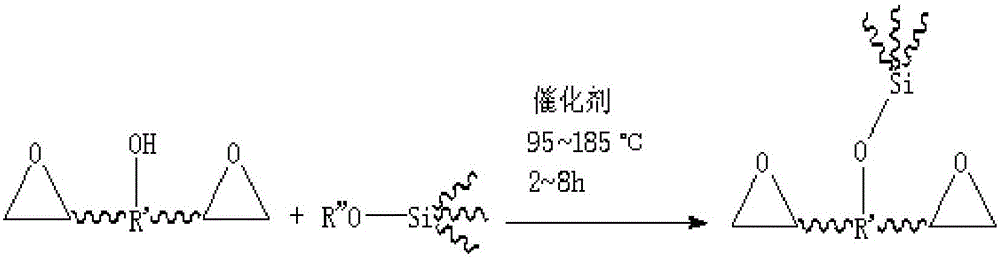

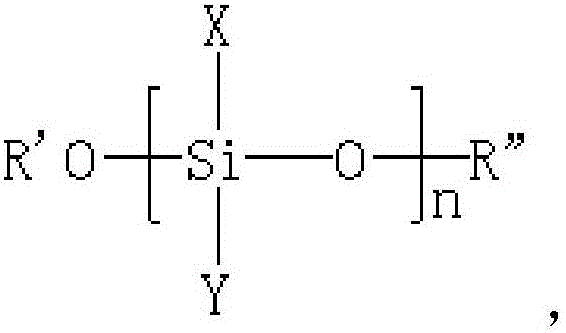

Method used

Image

Examples

Embodiment 1

[0030] Take 10g of silicone intermediate Dow Corning RSN-6018, 15g of epoxy resin E20, and 25g of a mixture of cyclohexanone and butyl acetate, and add them to a clean 500ml four-necked flask in sequence, stir slowly and heat up to 75°C, and wait for After mixing evenly, add 0.05g of zinc naphthenate, then heat up to 125°C, react for 4.5h, and continuously separate the water generated during the reaction, and lower the temperature to obtain a silicone-modified epoxy resin.

[0031] Obtained product technical indicators:

[0032] Initial decomposition temperature: 320°C;

[0033] Hardness: 5H;

[0034] Adhesion: Grade 1.

Embodiment 2

[0036] Take 10g of silicone intermediate Dow Corning RSN-6018, 30g of epoxy resin E20, and 40g of a mixture of cyclohexanone and butyl acetate, and add them to a clean 500ml four-neck flask in turn, stir slowly and heat up to 75°C, and wait for After mixing evenly, add 0.1 g of zinc naphthenate, then heat up to 145° C., react for 5.5 hours, and continuously separate out the water generated during the reaction, and lower the temperature to obtain a silicone-modified epoxy resin.

[0037] Obtained product technical indicators:

[0038] Initial decomposition temperature: 280°C;

[0039] Hardness: 5H;

[0040] Adhesion: Grade 1.

Embodiment 3

[0042] Take 10g of silicone intermediate Dow Corning RSN-6018, 45g of epoxy resin E20, and 55g of a mixture of cyclohexanone and butyl acetate, and add them to a clean 500ml four-necked flask in turn, stir slowly and heat up to 75°C, and wait for After mixing evenly, add 0.13 g of zinc naphthenate, then heat up to 155° C., react for 6 hours, and continuously separate out the water generated during the reaction, and cool down to obtain a silicone-modified epoxy resin.

[0043] Obtained product technical indicators:

[0044] Initial decomposition temperature: 240°C;

[0045] Hardness 4H;

[0046] Adhesion: Level 0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Onset decomposition temperature | aaaaa | aaaaa |

| Onset decomposition temperature | aaaaa | aaaaa |

| Onset decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com