Sound-absorbing cotton for noise-reduction automobile exhaust pipe

A technology of automobile exhaust and sound-absorbing cotton, which is applied in the direction of exhaust devices, noise reduction devices, mechanical equipment, etc., can solve the problem that the exhaust pipe does not have a noise reduction function, and achieves simple structure, excellent sound absorption performance, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

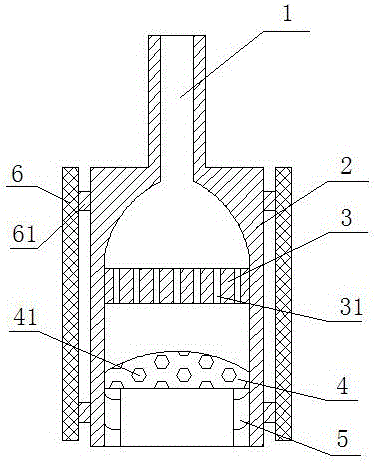

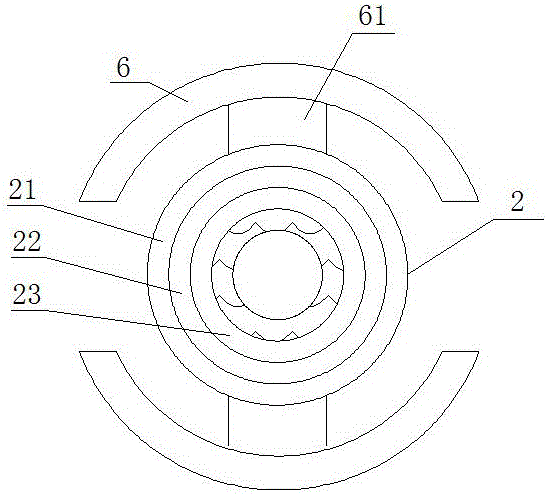

[0024] like Figure 1 to Figure 2 As shown, the present invention provides a noise reduction automobile exhaust pipe, which includes an intake pipe 1, a noise reduction cavity 2 communicated with the intake pipe 1, and a noise reduction plate 6 arranged on the outer wall of the noise reduction cavity 2. Enter the noise reduction cavity 2 for noise reduction. The noise reduction plate 6 is connected to the outer wall of the noise reduction cavity 2 through the connecting plate 61 .

[0025] Specifically, the inner space on the side of the noise reduction cavity 2 communicating with the air intake pipe 1 gradually increases in the intake direction, so that the exhaust pressure entering the noise reduction cavity 2 is reduced to achieve the purpose of noise reduction.

[0026] Further, a diverter 3 is arranged inside the noise reduction cavity 2; the diverter 3 is provided with several diverter channels 31; One side of the diverter 3 is provided with a hemispherical inner tank ...

Embodiment 2

[0030] Sound-absorbing cotton for noise reduction automobile exhaust pipe, composed of 40% epoxy resin, 45% polyether polyol DMN-3050, 5% diethanolamine, 5% 1,4-butanediol, 2% isobutyl vinyl ether and Made from 3% N-tert-butyl-2 benzothiazole sulfenamide.

Embodiment 3

[0032] The preparation method of sound-absorbing cotton for noise reduction automobile exhaust pipe, the steps are as follows:

[0033] 1), add epoxy resin, diethanolamine and 1,4-butanediol into the mixer A and mix well, adjust the constant material temperature to 25°C, and adjust the speed of the mixer to 3000r / min;

[0034] 2) Pour the polyether polyol DMN-3050, isobutyl vinyl ether and N-tert-butyl-2 benzothiazole sulfenamide preheated to 25°C into the mixture A in turn, and stir for 5 minutes to obtain mixed material B;

[0035] 3) Pour the mixed material B into a sound-absorbing cotton mold preheated to 40°C, and demold it after 5 minutes to obtain a sound-absorbing cotton product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com