Slurry pump control device and control method thereof

A technology for control devices and mud pumps, applied in pump control, liquid variable displacement machinery, machines/engines, etc., can solve problems such as reduced construction efficiency, hidden dangers to workers' personal safety, and exhaust gas pollution, so as to eliminate potential safety hazards and save manpower Resources and the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

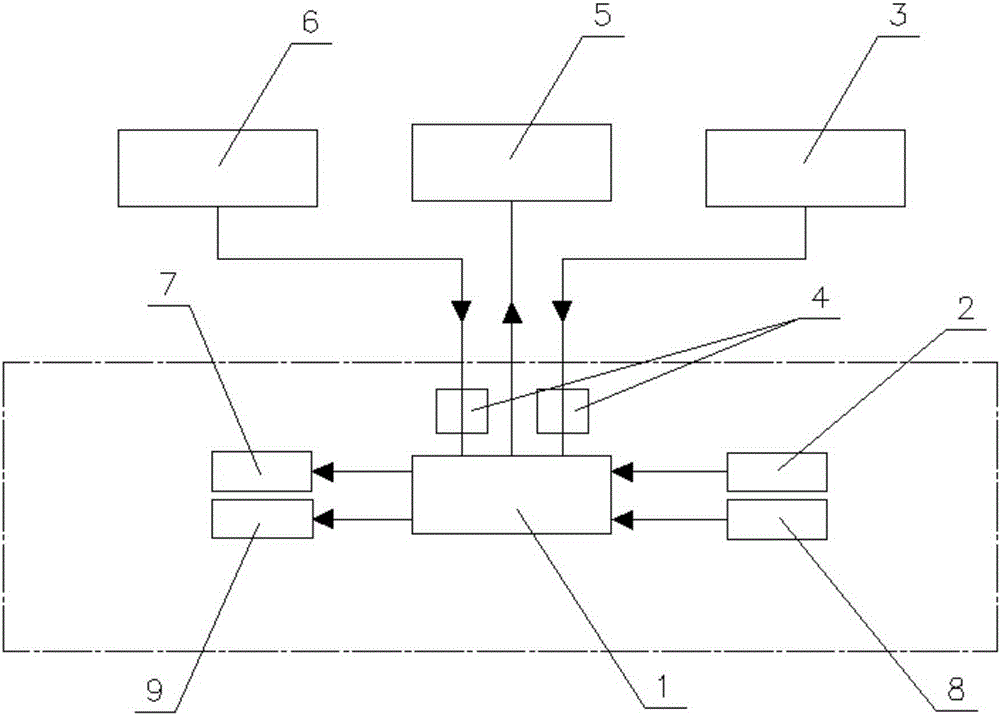

[0014] like figure 1 As shown, a mud pump control device includes a programmable controller 1, an operation panel 2, an engine sensor 3 and a transmitter 4; the operation panel 2 is connected with the programmable controller 1, and the programmable controller 1 is connected with the mud pump 5 connection, the engine sensor 3 is connected to the programmable controller 1 through the transmitter 4; the programmable controller 1 receives the instructions from the operation panel 2, and then sends the signal to the mud pump 5 to control the separation and closing of the clutch of the mud pump 5 And the engine start, flameout and accelerator opening of the mud pump 5; the engine sensor 3 sends the parameter information of the engine to the programmable controller 1 through the transmitter 4; when the programmable controller 1 determines that the engine is abnormal, it sends a specific command To the mud pump 5, the mud pump 5 executes a specific command, that is, the engine of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com