Method for manufacturing microbridge of uncooled infrared focal plane detector and structure thereof

A focal plane detector, uncooled infrared technology, applied in the direction of electric radiation detectors, etc., can solve the problems of not too much contribution, no signal response, contribution, etc., to reduce the proportion of invalid absorption, improve absorption efficiency, and improve absorption The effect of proportion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

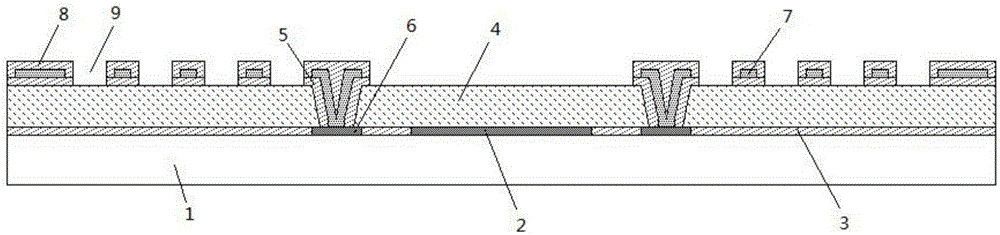

[0053] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

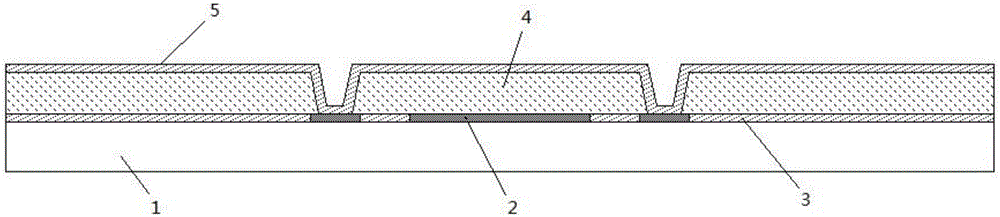

[0054] An embodiment of the present invention provides a method for making an uncooled infrared focal plane detector microbridge, see Figure 1 to Figure 8 , its specific process steps are as follows:

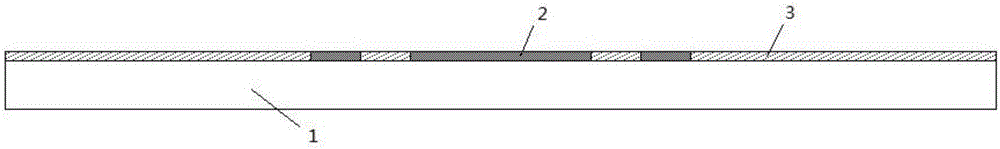

[0055] Such as figure 1 As shown, the reflective layer 2 is made on the wafer with the readout circuit 1 as the base, the material used for the reflective layer 2 is metal, and the thickness of the metal film is The reflection rate of reflective layer 2 metal to infrared light of specific wavelength (such as 8 ~ 14um) is more than 99%. After etching the reflective layer 2, an insulating dielectric layer 3 is deposited on the pattern of the reflective layer 2. The insulating dielectric layer 3 can be made of Si 3 N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com