Dynamic testing device and dynamic testing method for burning speed of initiative laser type solid rocket propellant

A solid rocket, dynamic testing technology, applied in the use of devices that measure the time required to move a certain distance, radio wave measurement systems, chemical analysis using combustion, etc. The problems of inaccurate burning rate test of solid propellant have achieved the effect of high test accuracy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the following embodiments will specifically describe the inventive active laser type solid rocket propellant burning rate dynamic testing device and method in conjunction with the accompanying drawings.

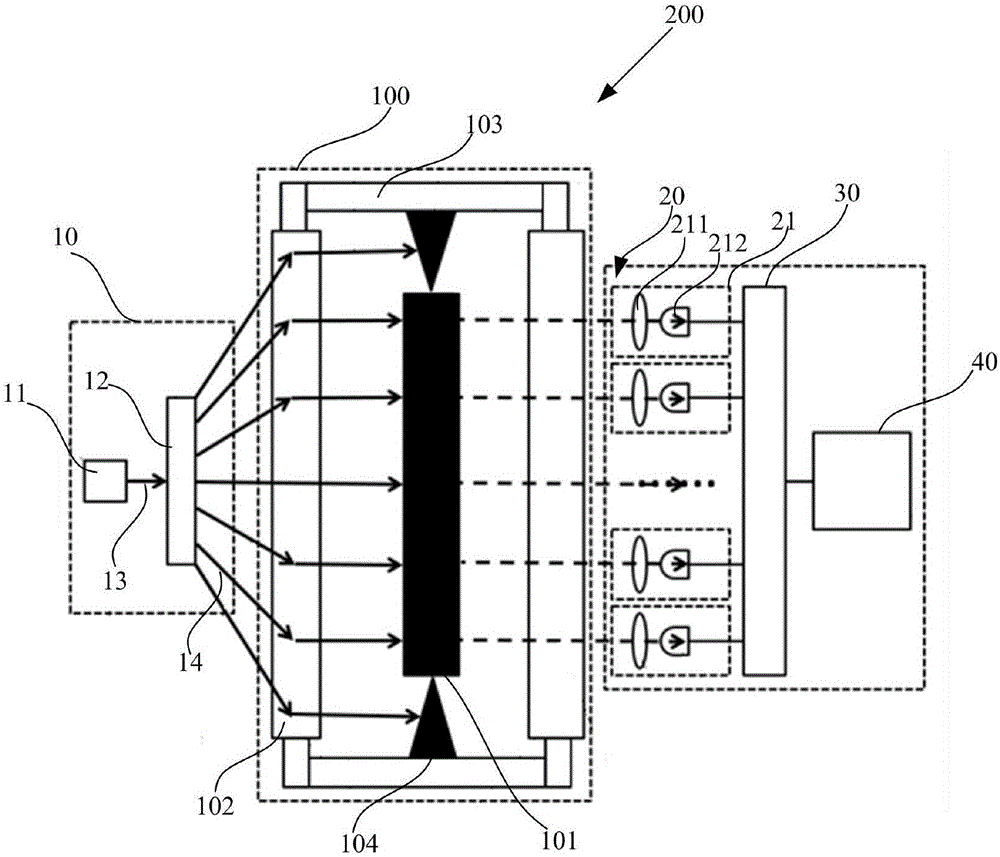

[0018] figure 1 It is a structural schematic diagram of the active laser type solid rocket propellant burning rate dynamic testing device of the present invention.

[0019] Such as figure 1 As shown, the active laser type solid rocket propellant burning rate dynamic test device 200 is used to dynamically test the burning rate of the medicine bar 101 in the combustion chamber 100 .

[0020] The combustion chamber 100 is an airtight container, the pressure in which can be adjusted, and is used for testing under specific experimental conditions. The combustion chamber 100 includes a combustion chamber main body 103 and two light-transmitting windows 102...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com