Full-automatic closed-loop testing system for fault indicator

A fault indicator, fully automatic testing technology, applied in the direction of instruments, measuring devices, measuring electrical variables, etc., can solve rough simulation of short circuit/ground fault, not suitable for batch fault indicator inspection, the console and the master station system are not integrated Together and other problems, to achieve the effect of simplifying the inspection method, high level of automation, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

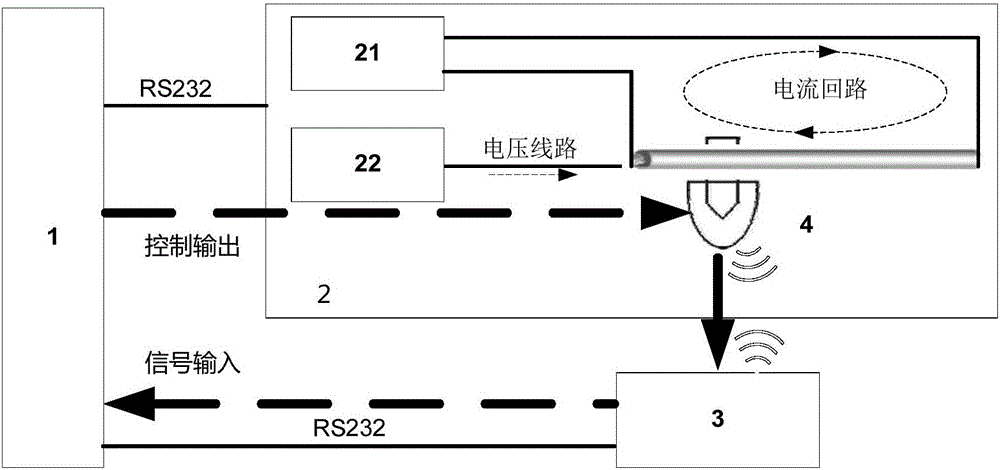

[0028] Such as figure 1 As shown, a closed-loop full-automatic testing system for a fault indicator includes a console 1 embedded with an analog master station, a testing unit 2 and a monitoring unit 3, and the console 1, testing unit 2, and monitoring unit 3 and the console 1 are connected in turn to form a closed loop, and the test unit 2 includes a voltage source 22 and a current source 21 connected to the console 1 respectively, and the voltage source 22 and the current source 21 are respectively connected to the fault indicator to be tested 4, the fault indicator 4 to be tested is connected to the monitoring unit 3, and the console 1 is connected to the fault indicator 4 to be tested.

[0029] The console 1 is connected to the voltage source 22, the current source 21 and the fault indicator 4 to be tested respectively through the RS232 bus. The fault indicator 4 to be tested is connected with the monitoring unit 3 through a wireless transmission network. The wireless tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com