A motor that suppresses high-frequency vibration and noise without an external filter inductor

A filter inductor and high-frequency vibration technology, applied in the direction of suppressing electromagnetic interference, etc., can solve the problems of insignificant influence on the total vibration level, large inductance volume, and large switching loss, etc., and achieve light weight, small system volume, and small switching loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

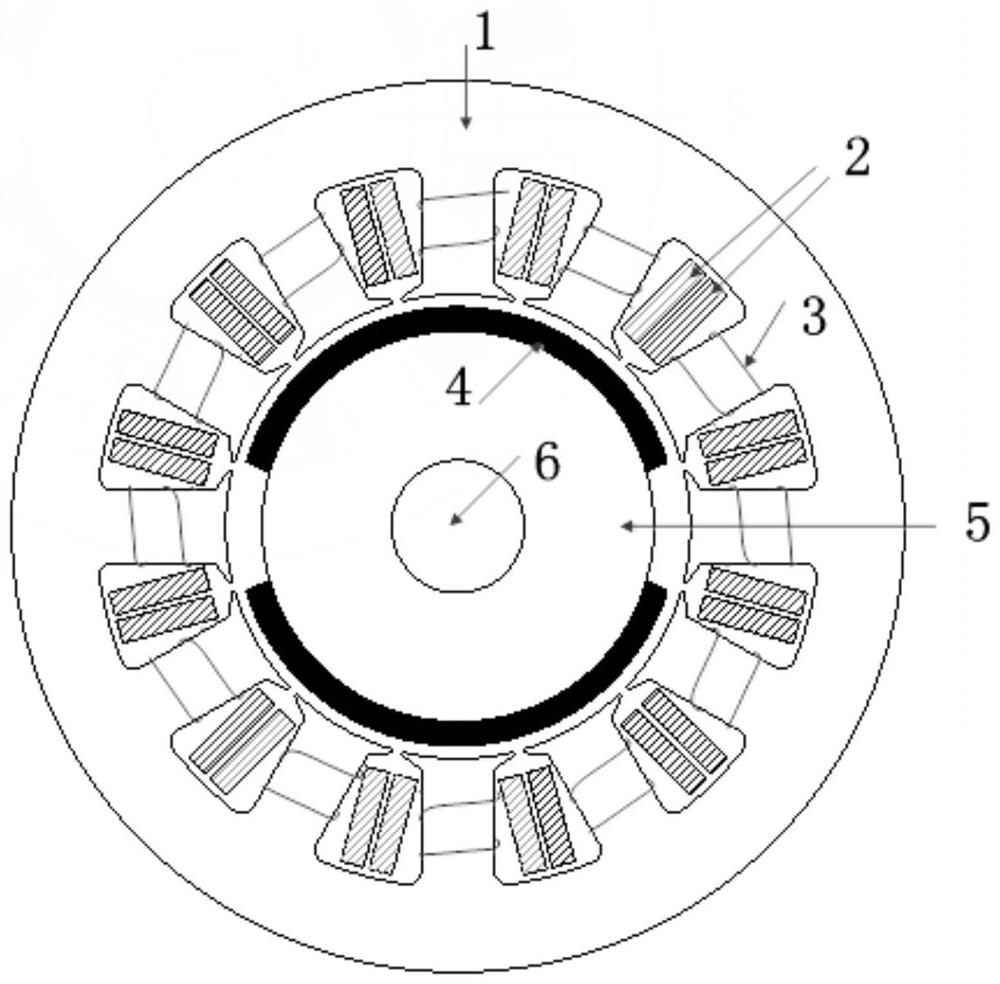

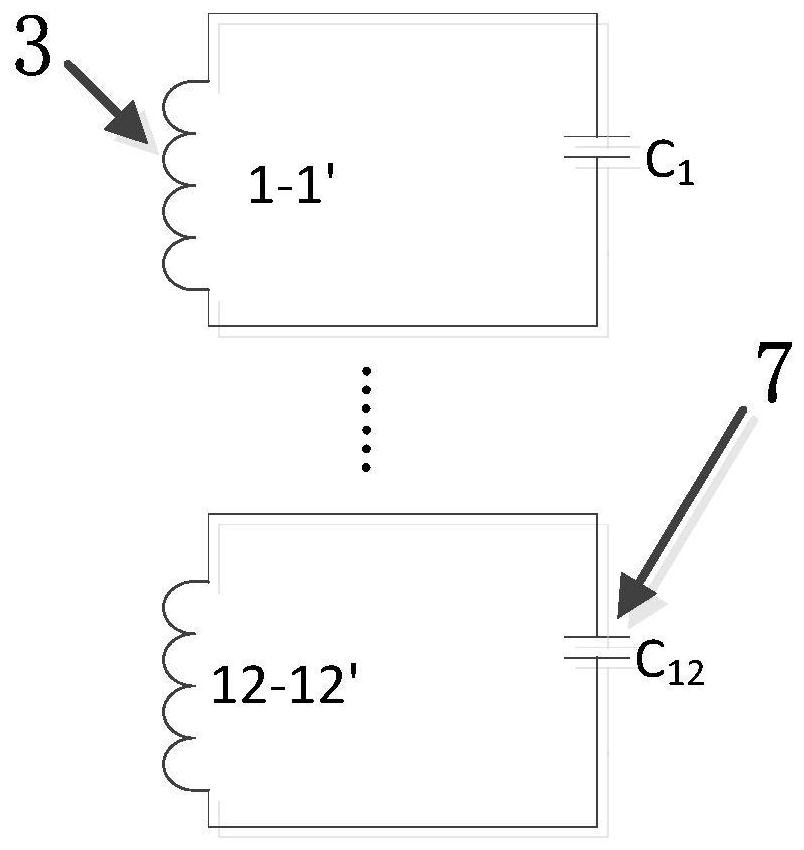

[0031] Such as Figure 4 As shown, the main winding 2 adopts a three-phase winding, and only the A-phase winding is shown in the figure. The stator filter winding 3 is arranged around each stator tooth, and the number of coils of the stator filter winding 3 is set as many teeth as the motor has; the number of turns of each coil of the stator filter winding 3 can be set as required. Figure 4 The middle stator filter winding 3 has a total of 12 coils, 1-1' constitutes a coil, 2-2' constitutes a coil, ..., 12-12' constitutes a coil.

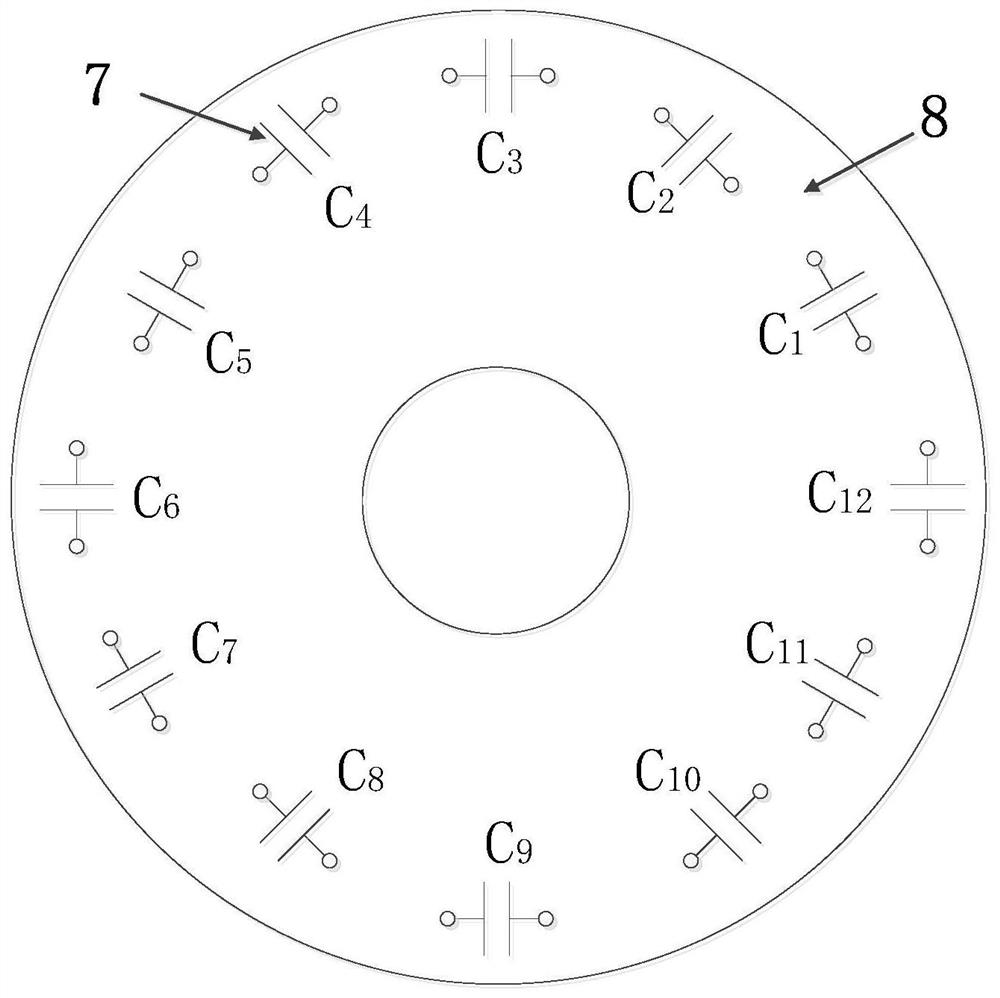

[0032] Such as image 3 As shown, there are a total of 12 independent loops composed of stator filter winding 3 and filter device 7 in this embodiment, of which 1-1’,...12-12’ are figure 2 The coil of the stator filter winding 3 shown in C 1 ,...C 12 It is the filter capacitor.

[0033] Such as figure 2 As shown, the capacitance C 1 ,...C 12 It is arranged on the circuit board 8. In this embodiment, the circuit board 8 is fixed on the end cover and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com