Production equipment and method for foamed ceramic

A technology for foaming ceramics and production equipment, which is applied in ceramic molding machines, ceramic molding workshops, manufacturing tools, etc., can solve the problems of rough surface patterns, poor decorative effect, and tearing patterns, and achieves short construction period and universal equipment. High performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

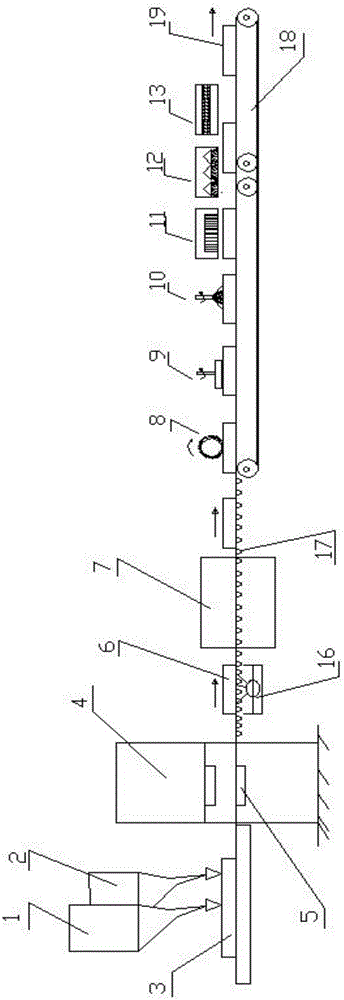

[0030] Embodiment 1: as figure 1 A schematic diagram of production equipment for foamed ceramics is shown. Its structure and process steps are as follows: the ceramic raw materials are batched, wet ball milled, and sprayed to granulate. The fabric in the material bin 1 and the bottom material in the bottom material bin 2 are sent to the secondary cloth in the mold cavity 5 of the press machine 4 through the powder feeding vehicle 3, and are pressed and formed. The green body 6 passes through the primer device 16, passes through the primer, is foamed and fired by the roller kiln 7, and then cooled, trimmed by the edge trimmer 8, and the surface is brushed by the surface brushing machine 9, 10, and the inkjet printing device 11 Inkjet printing decoration, spraying device 12 sprays transparent nano-silicon dioxide protective coating, curing 13 at 80-200 degrees Celsius for 50 minutes, wherein green body 6 is in roller kiln 7, curing machine 13; dryer 14 is transported by rollers,...

Embodiment 2

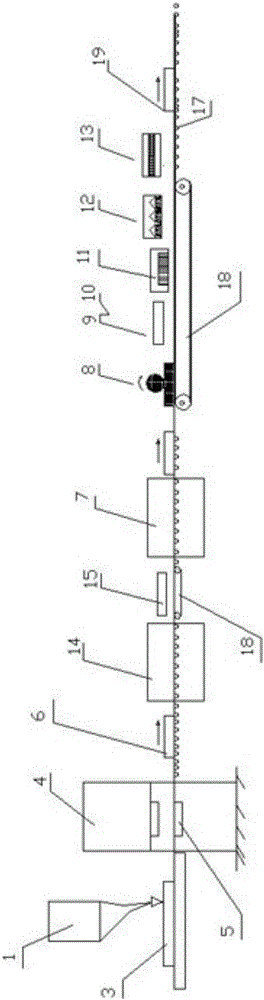

[0031] Embodiment 2: as figure 2 A schematic diagram of production equipment of another embodiment of a foamed ceramic is shown: its structure and process steps are: batching ceramic raw materials, dry grinding, and granulating. The powder is sent to the press 4 through the powder feeding vehicle 3 and pressed into the mold cavity 5 for pressing and molding, the drier 14 dries the body, the glazing machine 15 applies the surface glaze, the primer device 16 passes the primer, and foams through the roller kiln 7 Firing, cooling, trimming machine 8 trimming. Surface cleaning 10, inkjet printing device 11 inkjet printing decoration, spraying device 12 spraying transparent nano silicon dioxide protective coating, curing by curing machine 13 at 30-80 degrees Celsius.

[0032] In the production method of the above-mentioned equipment, raw material grinding can be processed by wet or dry processing, correspondingly there are atomization granulation and dry granulation. In order to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com