Highly-pure zinc arsenide preparation device and method

A preparation device, a technology for zinc arsenide, applied in chemical instruments and methods, arsenic compounds, inorganic chemistry, etc., can solve the problems of high process temperature, high energy consumption, long process time, etc., and achieve short time, high efficiency and purity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

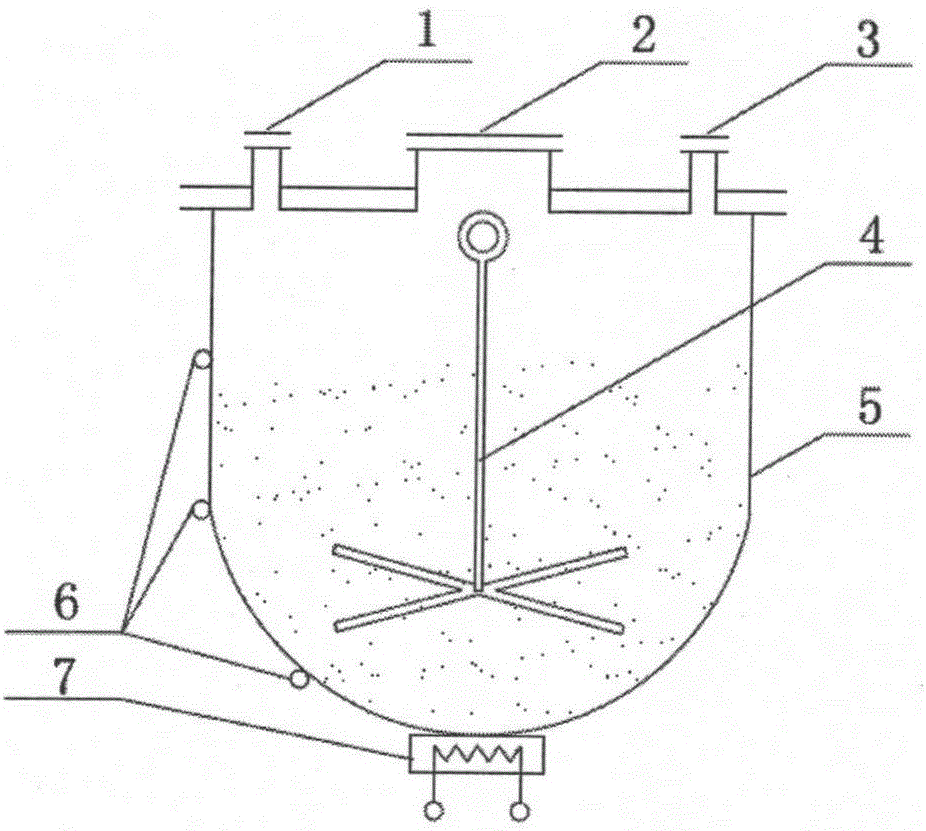

[0036] Such as figure 2 As shown, a preparation device for high-purity zinc arsenide includes a closed reactor 5, and the closed reactor 5 is provided with a protective gas inlet 1, a raw material charging port 2, an exhaust port 3, a temperature measuring element 6 and electric heater7. A product unloading rack 4 is arranged in the closed reactor 5 . The protective gas inlet 1 , the raw material charging port 2 and the exhaust port 3 are arranged on the top of the closed reactor 5 . The electric heater 7 is arranged at the bottom of the closed reactor 5 . The temperature measuring element 6 is arranged on the outer wall of the closed reactor 5 .

[0037] A method for preparing high-purity zinc arsenide, using the above-mentioned high-purity zinc arsenide preparation device, the specific steps are:

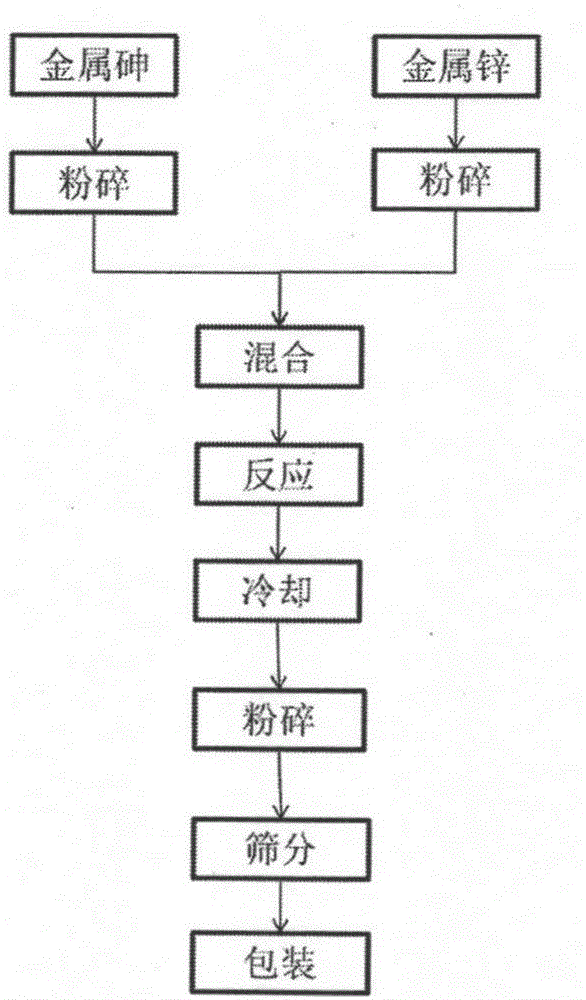

[0038] Raw material metal arsenic and metal zinc are pulverized with a ball ink pulverizer under nitrogen protection environment. Then pass through a sieving machine, sieve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com