Patents

Literature

38 results about "Hydrogen arsenide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Information provided on Hydrogen arsenide (7784-42-1) is for reference only and is subject to change. There is no warranty of accuracy or completeness of any information contained herein. ALS Environmental does not sell chemicals, but offers analytical lab testing to determine the presence of various elements and chemical compounds.

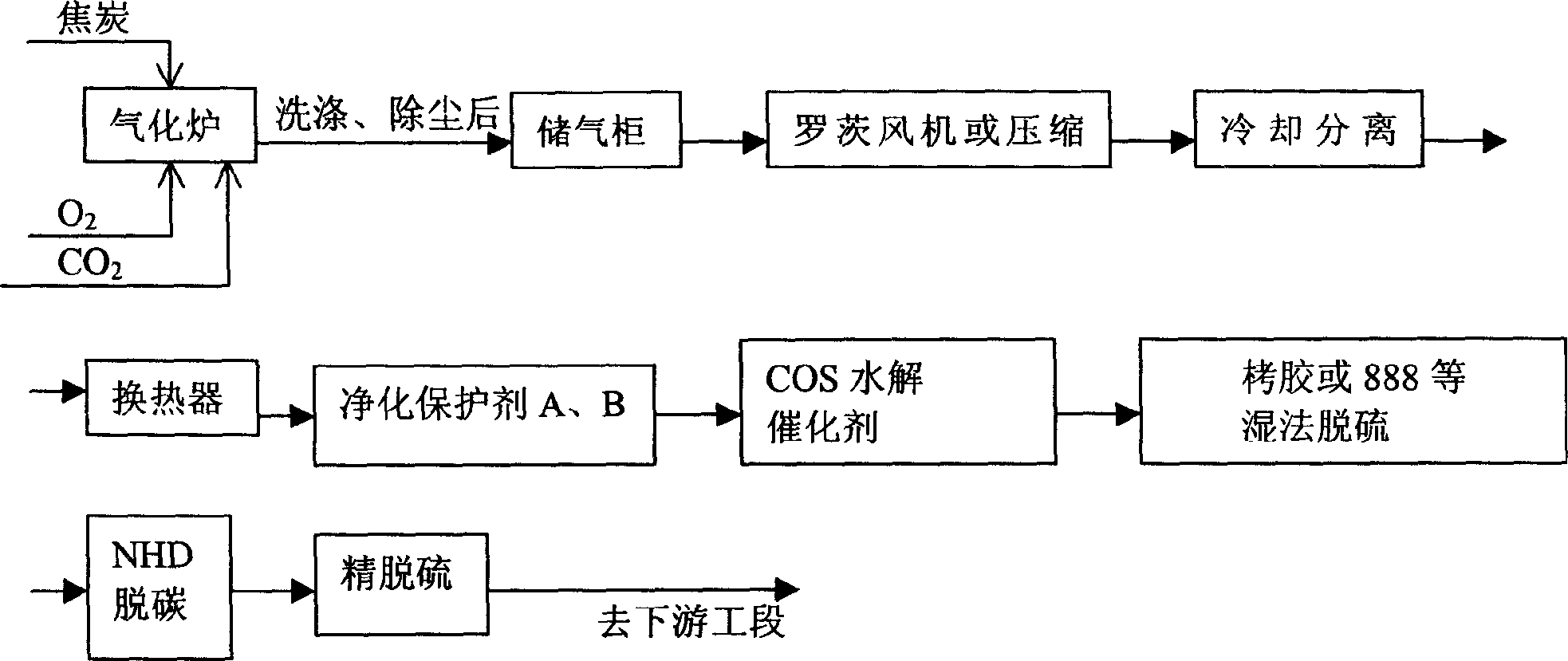

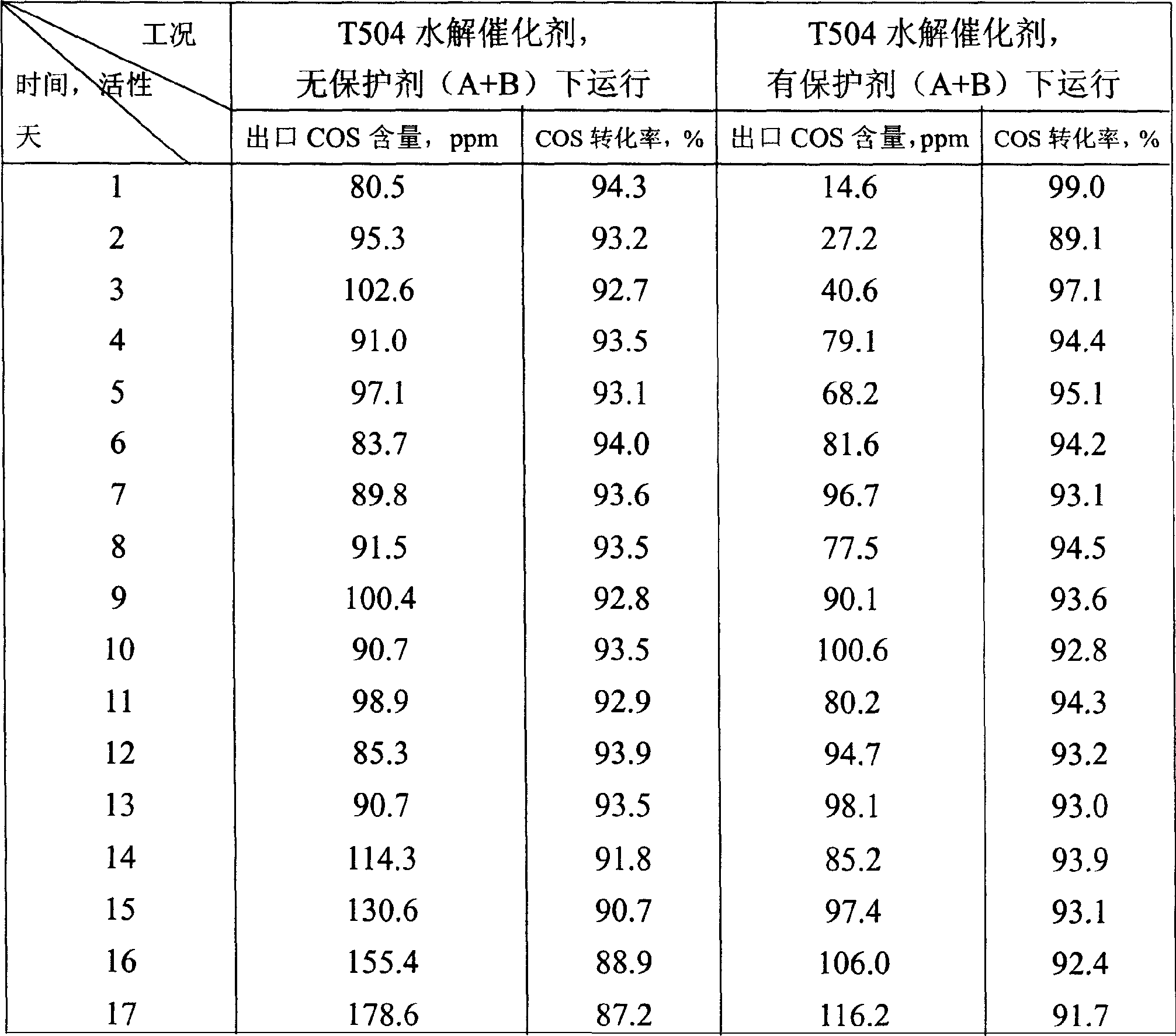

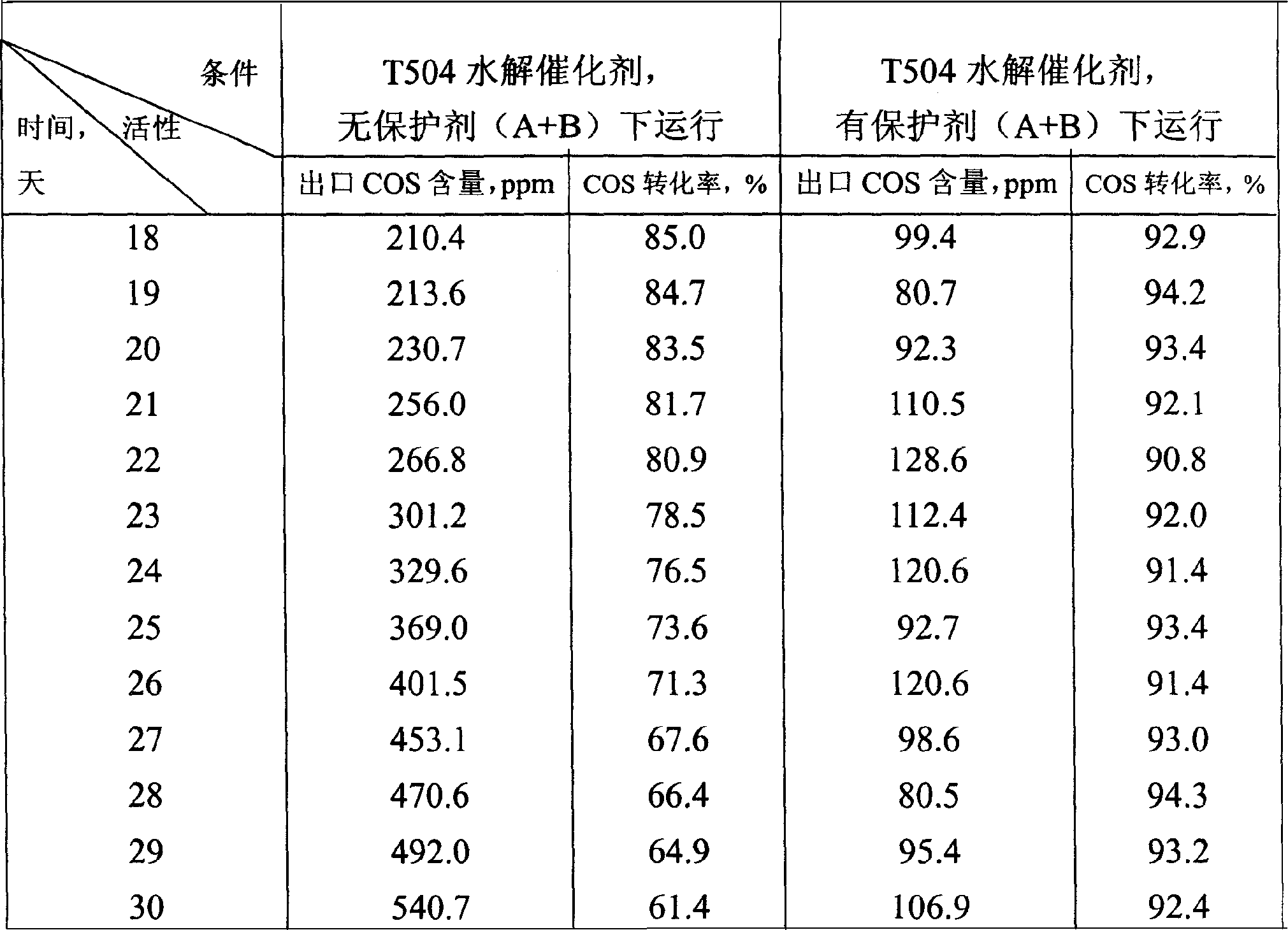

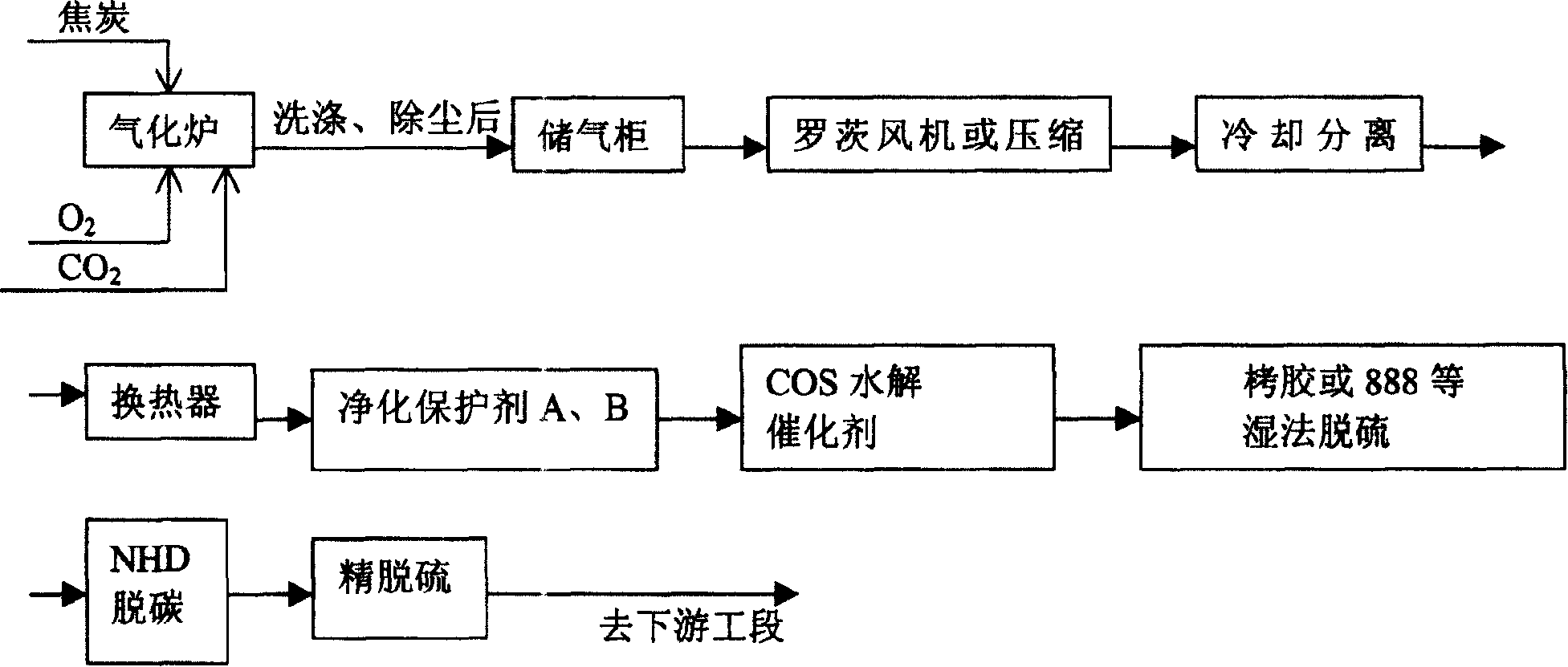

Process for preparing high purity carbon monoxide gas by desulfurization of organic sulfur at low and normal temperature

ActiveCN1844326AAchieve recyclingImprove and protect the ecological environmentCombustible gas purificationPoly(ethylene glycol) dimethyl etherDesorption

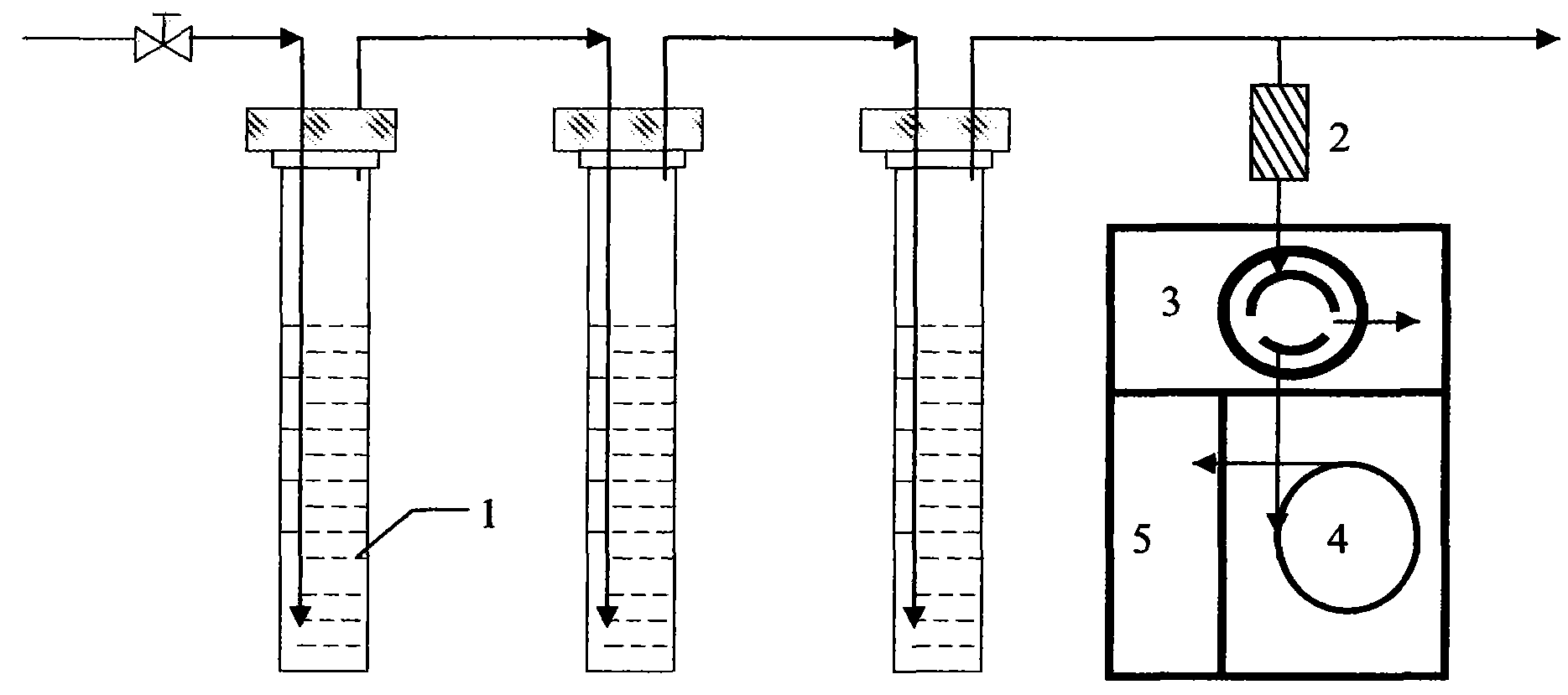

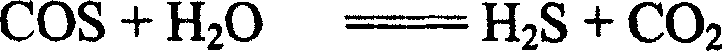

The invention relates to a technology for removing organic sulfur at a low or normal temperature to prepare high-purity carbonic oxide gas. The method consists of gasifying the coke with carbon monoxide or carbon dioxide to prepare the raw gases including 10 % -99 % CO, 0.1 %-90 % CO2, 0.001 %-2 % O2, 50-9000ppm COS, 10-10000ppm H2S, through gas storage holder, after pressurization and pyrogenation, entering purification tower filled with puripreservatives of A and B to remove hazardous materials including nitrogen oxide, hydrogen arsenide, hydrogen phosphide, hydrogen chloride, hydrogen nitrile, oxides of sulfur and sulfureted hydrogen, entering tower for removing organic sulfur filled with sulfur carbonyl hydrolyst, hydrolyzing 85%-95% of sulfur carbonyl for conversion into sulfureted hydrogen, at 20-150 DEG C, with a pressure of 0.1-10 MP, in which the refined raw gases can be used by productions of fine chemical industry including downstream acetate, dimethyl formamide,dimethyl ether, toluene diisocyanate or methyl diphenylene diisocyanate. The technology converts 85 %-95 % of sulfur carbonyl into sulfureted hydrogen, can adopt routine wet desulfurization to replace polyethylene glycol dimethyl ether desulfuration,can carry out cycle utilization of carbon dioxide and sulfur carbonyl of decarburized desorption gases of polyethylene glycol dimethyl ether, and can carry out zero discharge of poison material of sulfur carbonyl, which is good for environmental conservation.

Owner:HAISO TECH +1

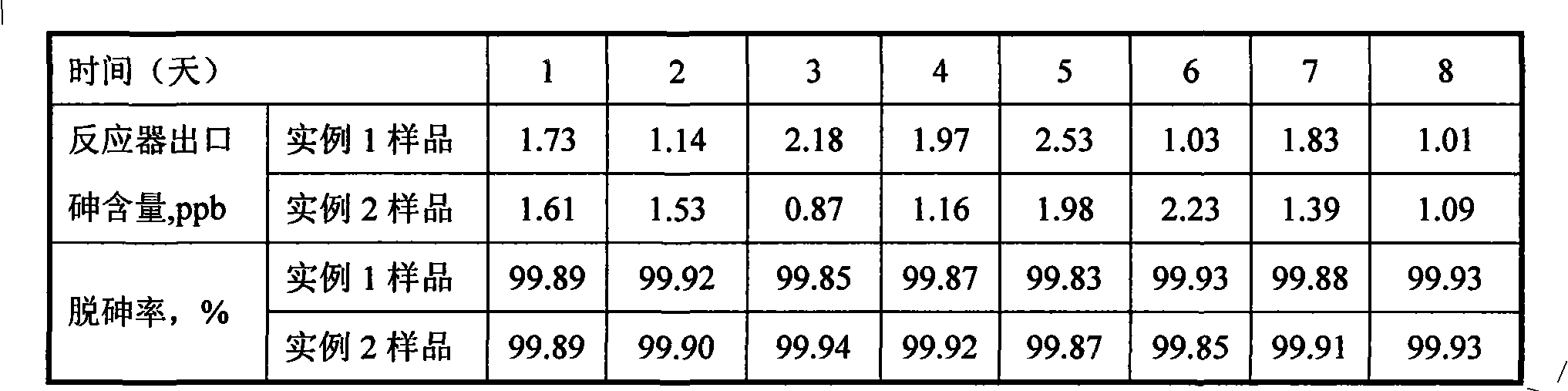

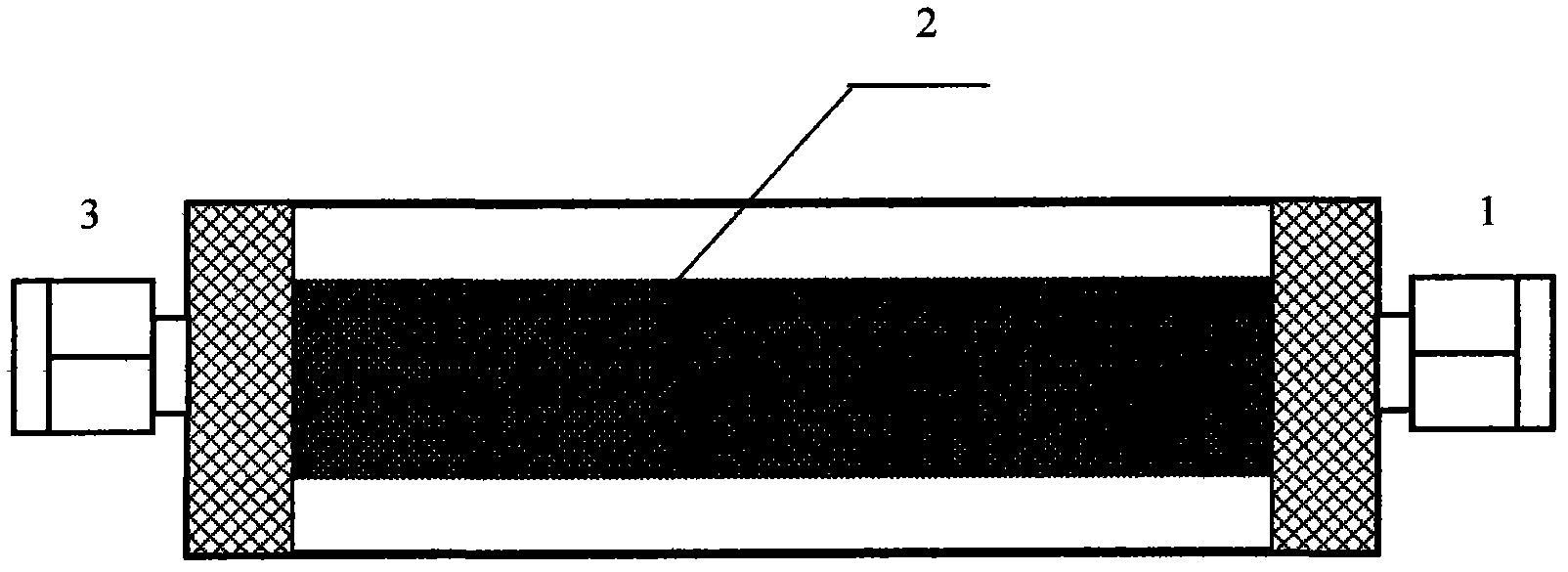

Purificant used for desulfuration of propylene and ethylene light hydrocarbon materials and preparation method thereof

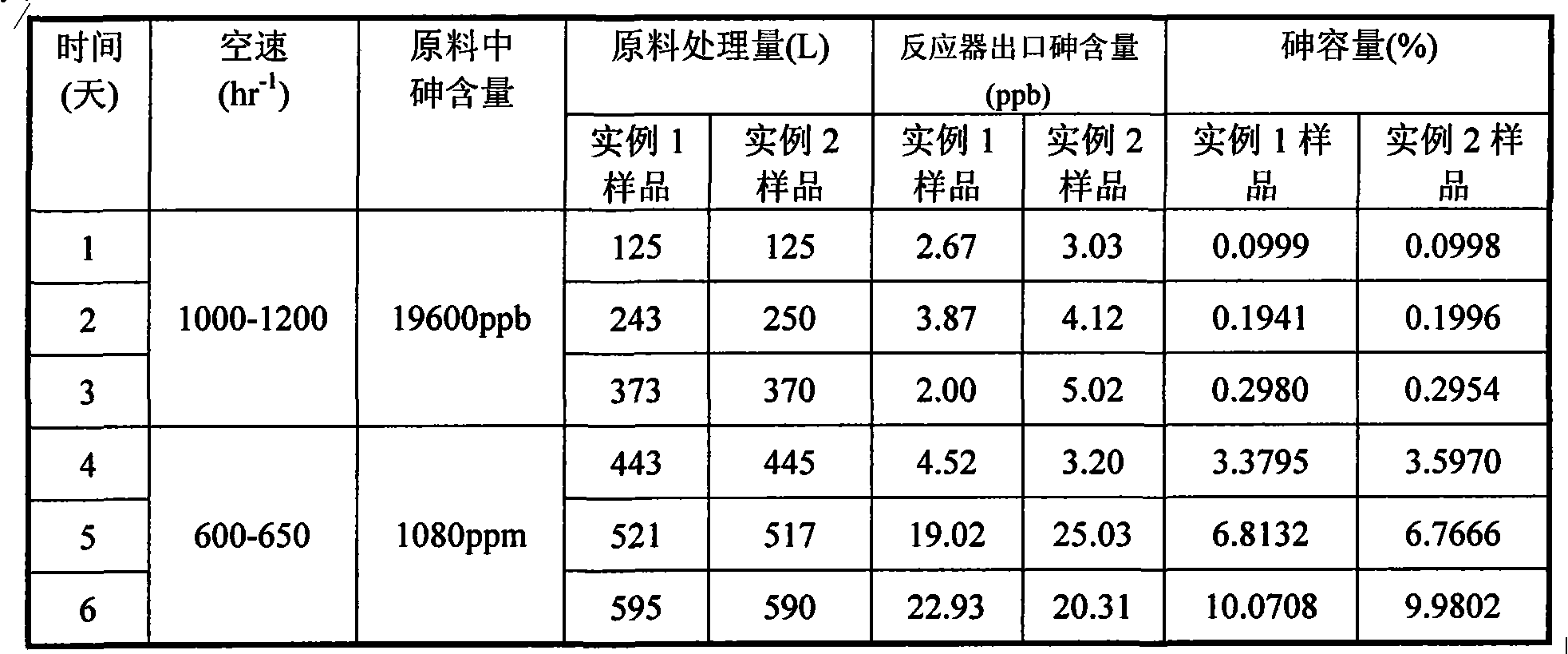

InactiveCN101602642AHigh precision of arsenic removalLarge arsenic capacityOther chemical processesAdsorption purification/separationHigh concentrationArsine

The invention relates to a purificant used for the desulfuration of propylene and ethylene light hydrocarbon materials. The purificant used for the desulfuration of propylene and ethylene materials takes alumina as a carrier, takes copper oxide as an active component, takes zinc oxide as an auxiliary agent and contains the following components according to the weight percent: 32-35% of CuO, 33-40% of ZnO and the balance of alumina. The purificant used for desulfuration does not need any preprocessing and can be directly used in the production technology of the desulfuration of the propylene and ethylene light hydrocarbon materials with high airspeed and high concentration of hydrogen arsenide. The purificant can be used at normal temperature, normal pressure and airspeed of 1200-2100hr-1, equivalent to the condition of the liquid airspeed of 4.5-8.0hr-1, and has the characteristics of high desulfuration precision and large arsenic capacity. The content of arsenic in raw materials can be removed from 1000ppm to less than 5ppb at normal temperature and normal pressure, the capacity of saturated arsenic reaches more than 30%, and the capacity of industrial effective arsenic is greater than 15%. Moreover, the purificant has a stronger desulfuration function.

Owner:LIAONING PROVINCE PETROLEUM CHEM IND PLANNING&DESIGNING INST

Purifier for adsorbing arsenic hydride and hydrogen phosphide in olefin tail gas and preparation method thereof

ActiveCN102806065AReduce contentSimple ingredientsOther chemical processesDispersed particle separationSimple componentAtmospheric pollution

The invention relates to a normal-temperature purifier for adsorbing arsenic hydride and hydrogen phosphide in an olefin tail gas, belonging to the atmospheric pollution purification field. The purifier comprises following components in percentages by mass: 0.5-5% of potassium permanganate, 1-10% of soluble copper salt, 1-10% of soluble zinc salt and 75-97.5% of active carbon; the active carbon is a carrier; the potassium permanganate, and the soluble copper salt and the soluble zinc salt are active components. The preparation method of the purifier comprises following steps: (1), preparing a mixed water solution of the potassium permanganate, the soluble copper salt and the soluble zinc salt; (2), loading the potassium permanganate, the soluble copper salt and the soluble zinc salt on the active carbon carrier by a dipping method to obtain a carrier loaded with active metals; and (3), drying the carrier loaded with active metals in a drying medium to obtain the finished product purifier. The purifier disclosed by the invention has the advantages of simple component, low cost and low usage cost; after the purification, the content of arsenic hydride and hydrogen phosphide is less than 10ppb (volume percentage).

Owner:CHINA PETROLEUM & CHEM CORP +1

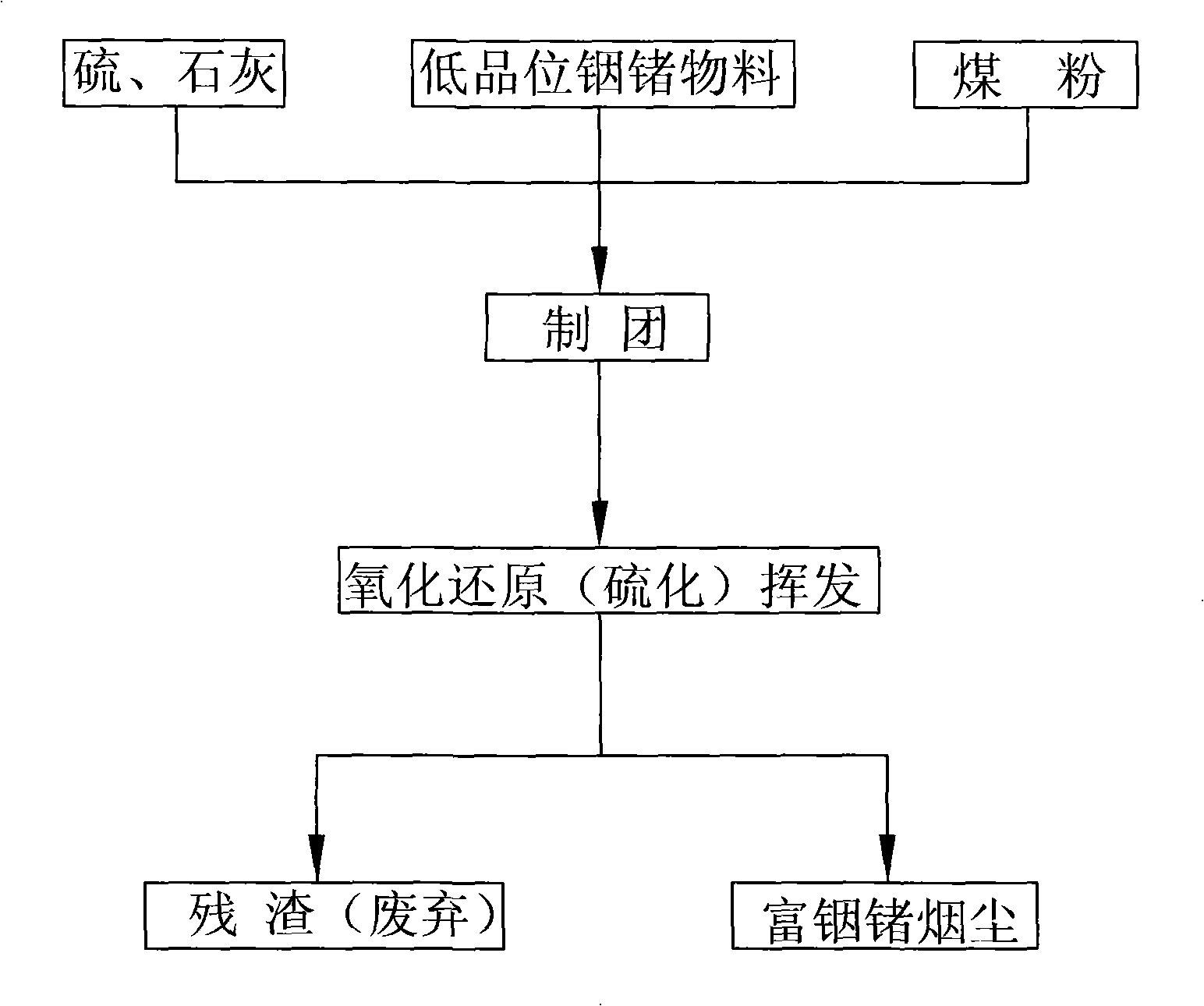

Method for vulcanization, reducing oxidation and enrichment of low-grade material containing arsenic, indium and germanium

ActiveCN101525693AFull recoveryReduce manufacturing costPhotography auxillary processesProcess efficiency improvementVulcanizationIndium

The invention relates to a method for the vulcanization, the reducing oxidation and the enrichment of a low-grade material containing arsenic, indium and germanium. The method comprises the following steps: compounding a certain amount of coal dust in a raw material containing indium, germanium, lead, zinc and arsenic as a reducer; meanwhile, adding elemental sulfur and a caking agent for briquetting by the weight ratio that the raw material containing the indium, the germanium, the lead, the zinc and the arsenic to lime to sulfur is equal to 100:20-40:5-10:2-4; making the material into a coalball or briquette shape, vulcanizing and volatilizing in a shaft furnace; controlling temperature to be below 1000 DEG C to 1200 DEG C and vulcanization volatilizes time to be from 1 hour to 3 hours under a certain oxidation reduction atmosphere, and the content of the lead and the zinc in slag to be less than 2 percent, and decreasing the content of the indium and the germanium to be 30 to 300 g / ton; leaching flue dust when a sulfur terminal has a pH value of 0.5 and replacing zinc powder for leaching liquid into indium-germanium concentrate ore. The method can take lower production cost to enrich valuable metals, such as indium, germanium, lead, zinc, silver and the like without drainage, the germanium, the indium and the zinc obtained in the flue dust can be leached by 95 percent when the pH value is 0.5, hydrogen arsenide can be separately treated, and the valuable metals of the lead, the zinc and the silver can be fully recycled.

Owner:SHENZHEN ZHONGJIN LINGNAN NONFEMET COMPANY

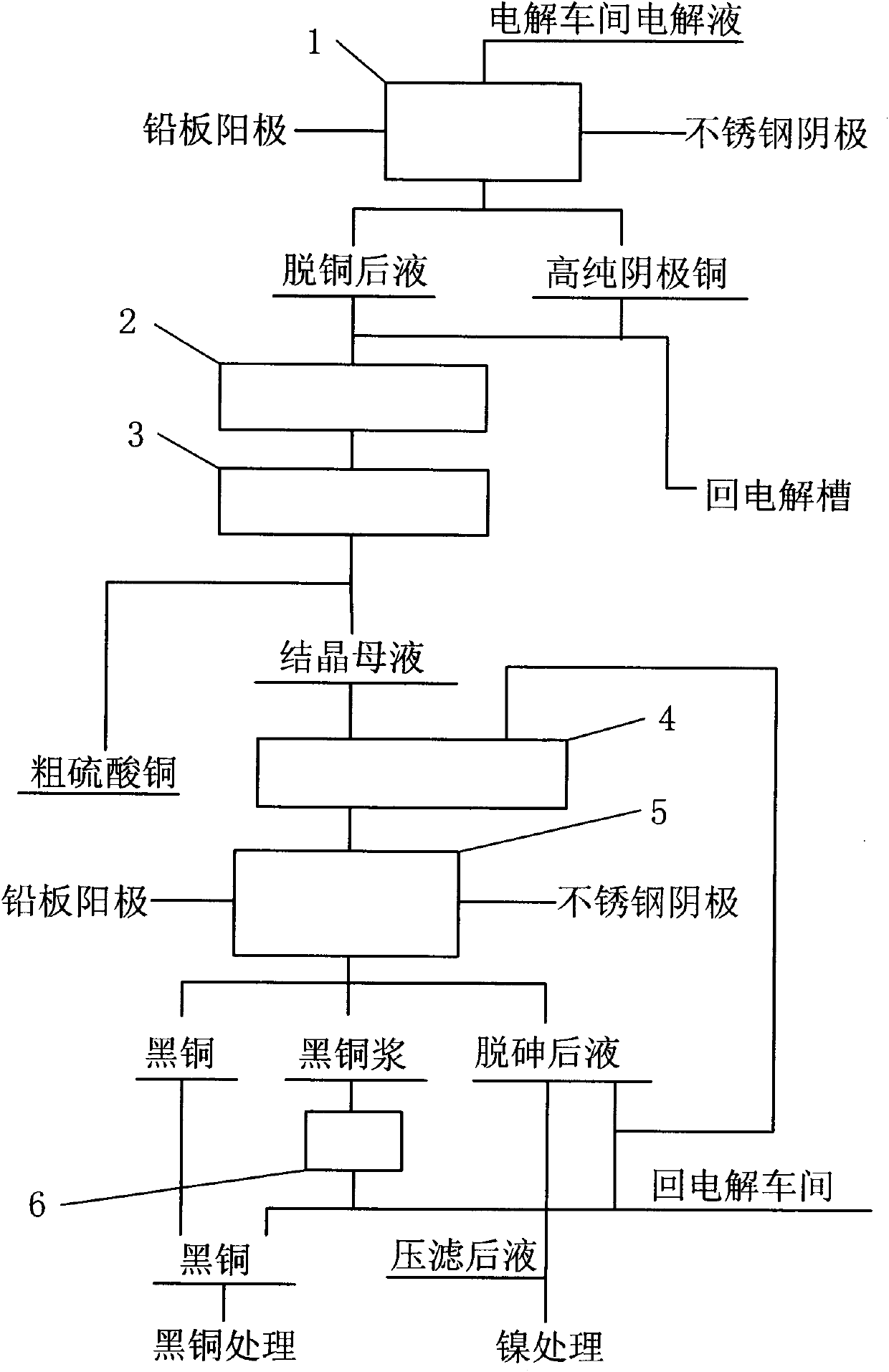

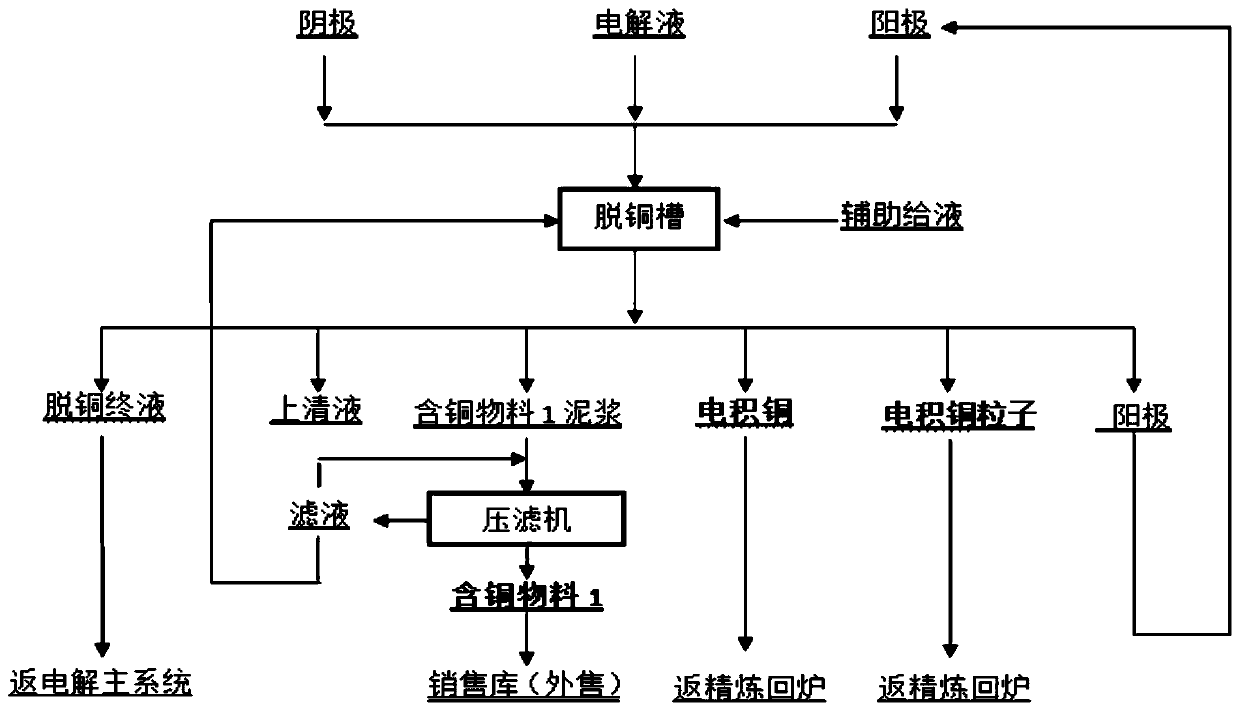

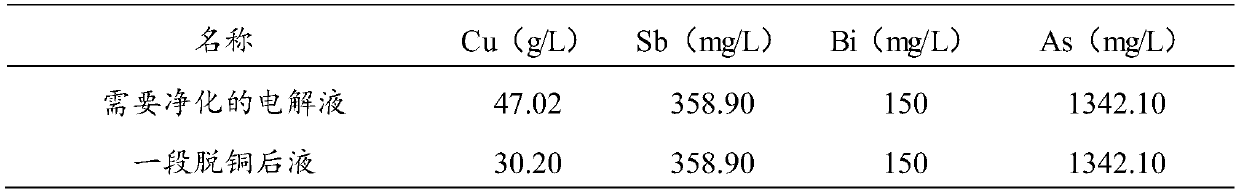

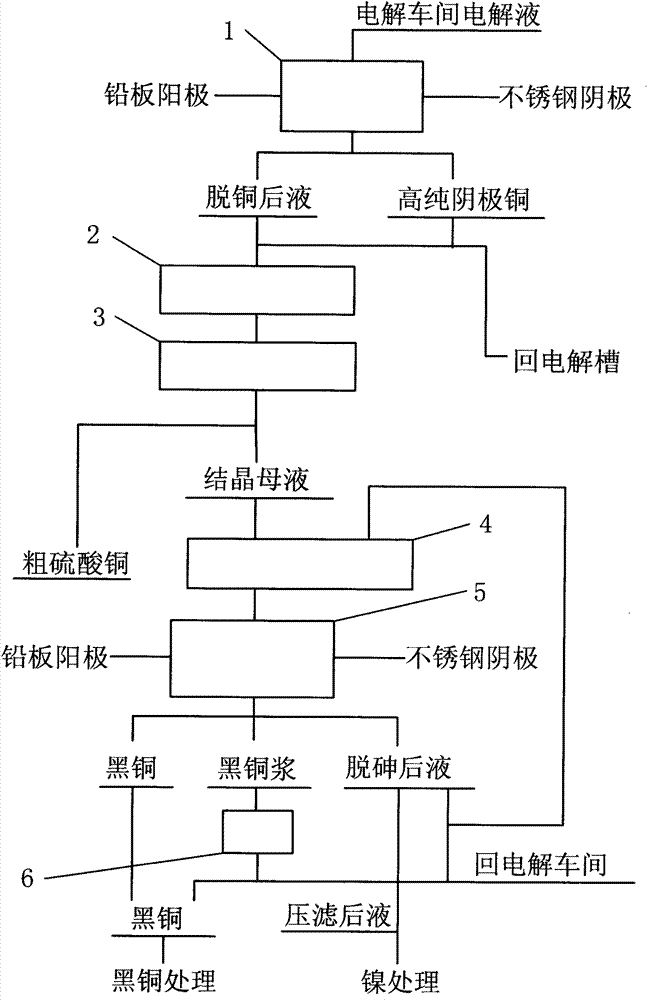

Method for purifying copper electrolyte with minimal chemical reacting dose

InactiveCN101906654AAvoid invalid removalEffective control of precipitationCellsElectrolysisChemical reaction

The invention relates to a method for purifying copper electrolyte, which belongs to the technical field of wet-process metallurgy. High-purity cathode copper, crude copper sulphate, black copper and nickel are obtained by the following steps of: removing copper by electro-deposition; evaporating and condensing liquid in vacuum after copper removal; crystallizing condensate after the copper removal to obtain copper sulfate; preparing electrolyte from which arsenic is removed; removing arsenic by the electro-deposition; and performing filter pressing on black copper slurry. Due to the adoption of the method of the invention, the electrolyte can be purified during copper electro-deposition and the arsenic is removed in the form of an arsenic-copper alloy, so that the production of hydrogen arsenide is controlled and the technical problem of realizing the purification of the copper electrolyte is solved. The method has the advantages of capability of preventing invalid removal of the copper and effectively controlling the separation of polluting AsH3, simple operation, low energy consumption and suitability for copper electrolytic purification process.

Owner:HULUDAO ZINC IND CO LTD

Method for purifying arsenic hydride gas in industrial waste gas

InactiveCN101402020ALow costLow releasabilityMolecular sieve catalystsDispersed particle separationFixed bedCalcination

The invention relates to a method for purifying hydrogen arsenide in industrial waste gas, which comprises the following steps: firstly, a mixed modified solution of a cobalt phthalocyanine solution and one ion or a plurality of ions of Fe<3+>, Mn<2+> and Ni<2+> is prepared; secondly, molecular sieve is placed into the modified solution, and modified molecular sieve catalyst is obtained after impregnation, drying and calcination; and thirdly, the modified molecular sieve catalyst is placed into a fixed bed reactor, and the industrial waste gas, including 80 to 90 volume percent of CO, less than 2 volume percent of O2 and 500 to 1600 milligrams per cubic meter of AsH3, undergoes solid catalysis, oxidation and purification, so that the content of the hydrogen arsenide in the industrial waste gas is reduced to below 0.3 milligram per cubic meter. The modified molecular sieve catalyst has high low-temperature activity, can be used in complex industrial gas atmosphere containing CO, H2S, SO2, COS, PH3 and so on, and has good selectivity on AsH3. The method can be applied in factories such as large-scale coke-oven plants, yellow phosphorus manufacturing plants, calcium carbide plants, and provides a feasible path for air pollution control and monocarbide chemical process development of China.

Owner:KUNMING UNIV OF SCI & TECH

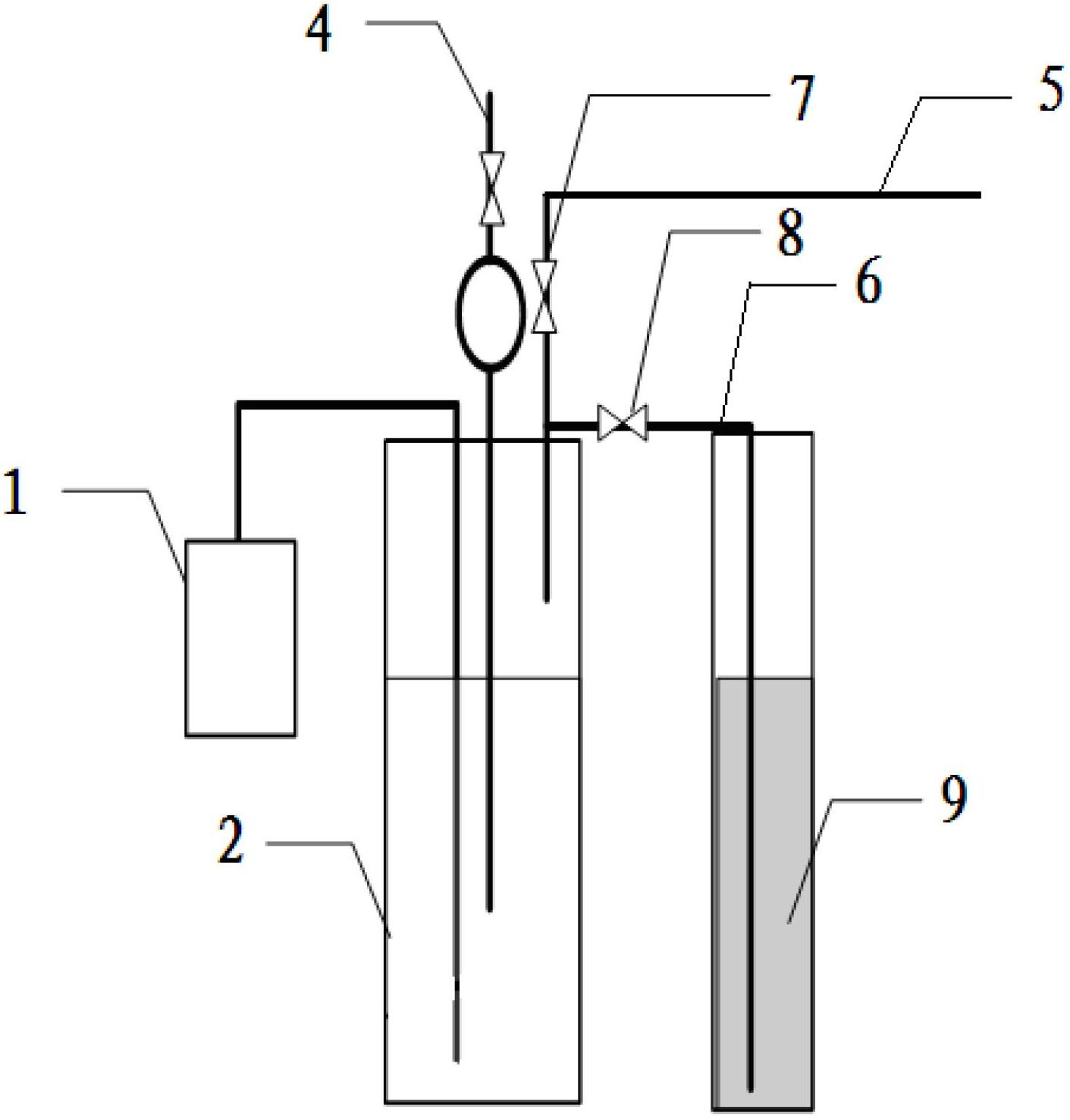

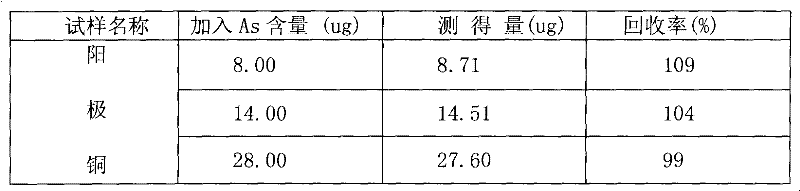

Method for detecting arsenic content in water body

ActiveCN102661925AReduce distractionsEffective interferencePreparing sample for investigationColor/spectral properties measurementsColor reactionHydrogen arsenide

The invention provides a method for detecting an arsenic content in a water body. The method comprises the following steps of: a) providing a sample to be detected, and mixing protonic acid with the sample to be detected containing hydrogen sulfide, so that the protonic acid and sulfide in the sample to be detected are reacted to generate the hydrogen sulfide; b) introducing air into the sample to be detected containing hydrogen sulfide, and removing hydrogen sulfide; c) mixing a reducing agent with the sample to be detected, so that an arsenious compound is reduced to be arsenic hydride; and d) absorbing arsenic hydride by using an absorbent and carrying out chromogenic reaction, detecting developed liquid through a spectrophotometry, and obtaining content of an arsenic element in the water body through calculation. The detection method provided by the invention not only can be used for effectively removing sulfide interference but also is environmentally-friendly and easy to operate. The invention further provides a device for detecting the arsenic content in the water body.

Owner:LIHE TECH (HUNAN) CO LTD

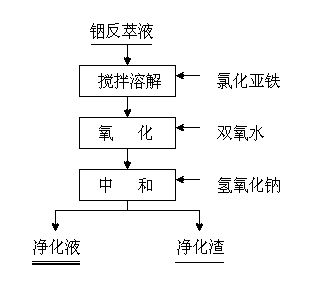

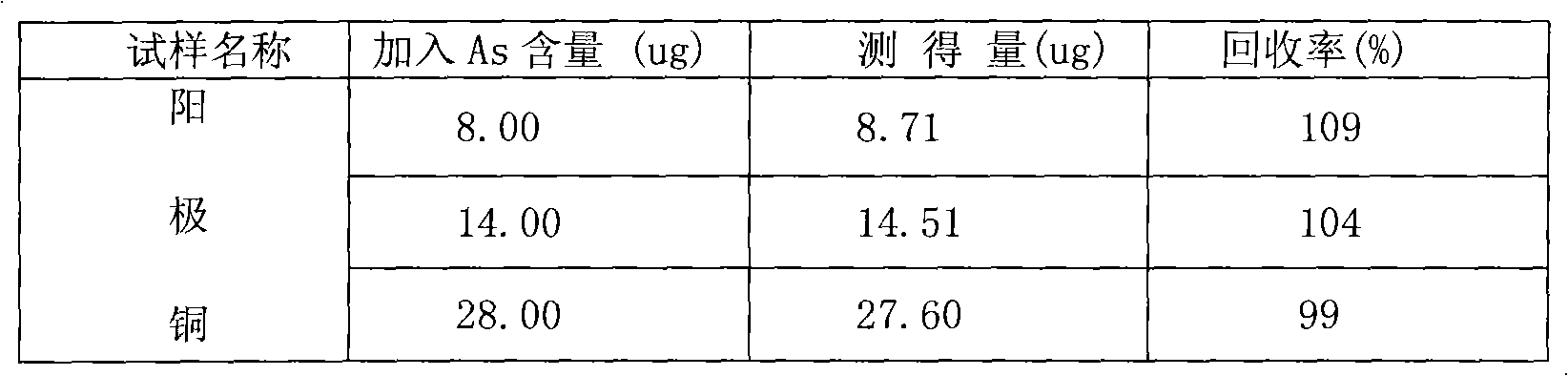

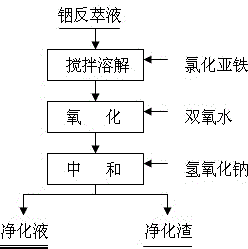

Purification method of indium back extraction solution

ActiveCN103014342AAvoid it happening againReduce consumptionProcess efficiency improvementIndiumPurification methods

The invention provides a purification method of indium back extraction solution, comprising the following steps: A, adding soluble ferrite in indium back extraction solution, and stirring for dissolving; B, under the condition of stirring, adding hydrogen peroxide, respectively oxidizing Fe2+ and Sn2+ in the solution into Fe3+ and Sn4+; C, adding sodium hydroxide till the pH value of the system is 2.0-2.5 so as to obtain neutralizer; and D, filtering so as to obtain scavenging solution and purifying residue. According to the purification method of indium back extraction solution provided by the invention, impurities in the indium back extraction solution such as ferrum, arsenium, stibium, bismuth, stannum and the like can be removed, the generation of poisonous gas hydrogen arsenide when indium back extraction solution displacement can be prevented, the consumption of zinc slabs in the displacement process is reduced, and conditions for obtaining high-grade crude indium in the next step are provided, and simultaneously valuable metals such as bismuth, stannum and the like are enriched so as to be beneficial for recycle. Simultaneously, the purification method provided by the invention is simple in technology, convenient to operate and low in production cost.

Owner:ZHUZHOU SMELTER GRP

Method for measuring arsenic by iodine solution absorption method

InactiveCN101788495AReduce usageReduce pollutionMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsHydrogenHydrazine compound

The invention discloses an accurate and reliable method for measuring arsenic by an iodine solution absorption method, which solves the problem that the traditional method produces poisonous waste liquor. In a H2SO4 medium greater than 3.6N, Zn reacts with an acid to produce nascent activated hydrogen; in the presence of KI and acidic SnCl2, As<5+> is reduced into As<3+>, and the trivalent arsenic reacts with the nascent activated hydrogen to produce hydrogen arsenide gas; and the hydrogen arsenide gas is absorbed by an iodine solution and is oxidized into quinquevalent arsenic. In a 0.25 equivalent sulfuric acid medium, the quinquevalent arsenic reacts with ammonium molybdate to produce yellow heteromolybdoarsenic acid. The heteromolybdoarsenic acid is reduced into arsenic molybdenum blue by hydrazine sulfatefor for colorimetric determination. The method for measuring arsenic by iodine solution absorption and the colorimetric determination of the arsenic molybdenum blue is more suitable for the analysis of As in raw materials for copper smelting and semi-finished products of matte anode copper; moreover, the use of poisonous and hazardous reagents is avoided, and environment pollution is reduced.

Owner:BAIYIN NONFERROUS GROUP

Method for germanium separation by inorganic precipitation of zinc hydrometallurgy solution

ActiveCN111996382ARealize the enrichment of germanium by inorganic precipitationAvoid introducingProcess efficiency improvementIon exchangeHydrometallurgy

Owner:KUNMING UNIV OF SCI & TECH

Technological method for producing acetylene by efficient calcium carbide process

ActiveCN107129830AImprove conversion rateHigh densityAcetylene gas generator detailsSolubilityInternal temperature

The invention provides a technological method for producing acetylene by an efficient calcium carbide process, which comprises the following steps: grinding calcium carbide, and then degressively adding into a vacuum reactor, wherein the internal temperature of the vacuum reactor is 45-55 DEG C and the vacuum reactor contains a mixture of a saturated salt solution and an alkaline water solution; controlling the temperature of the whole reaction system to be not higher than 70 DEG C; and introducing acetylene gas subjected to preliminary purification into an acidic water solution and concentrated sulfuric acid sequentially for carrying out secondary purification, so as to obtain highly pure acetylene gas. Compared with the prior art, the technological method provided by the invention has the following advantages: a generated pasty calcium hydroxide solid quickly settles so as to prevent the surface of powdered calcium carbide from being wrapped and affecting the continuous operation of the reaction; the gas production reaction is carried out under relatively mild conditions, and a baffle does not need to be arranged in the reactor; the solubility of non-polar acetylene gas in the solution is reduced, the solubility of polar gas, such as hydrogen sulfide, hydrogen phosphide and hydrogen arsenide, in the solution is increased, and the gas production rate and the acetylene gas purity are increased; and the reaction process and the preliminary purification process are carried out in one reactor, thereby saving the field.

Owner:HWASU

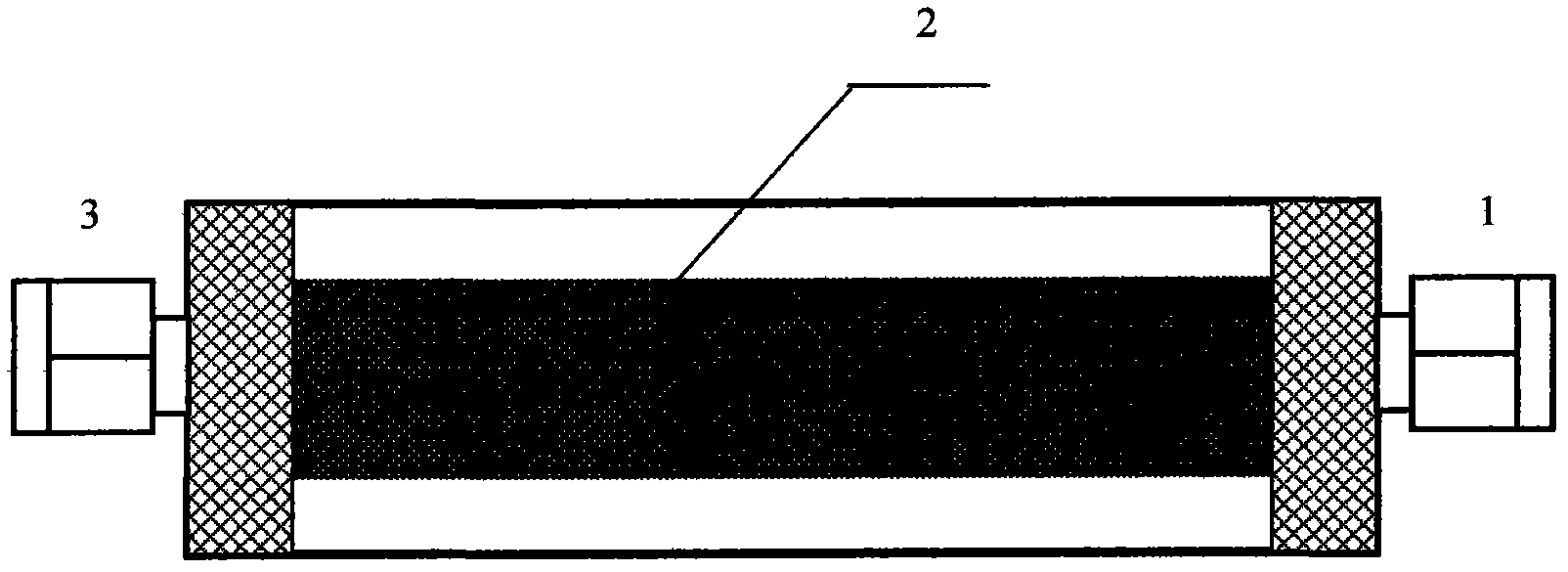

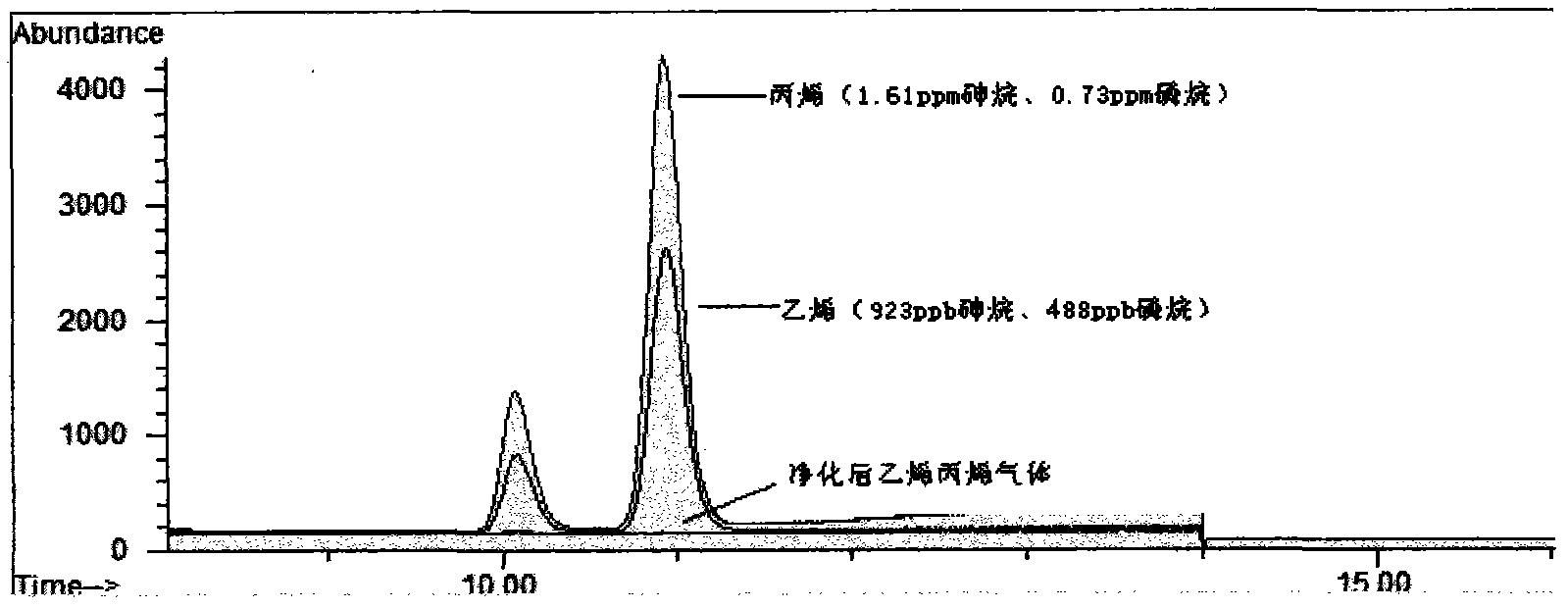

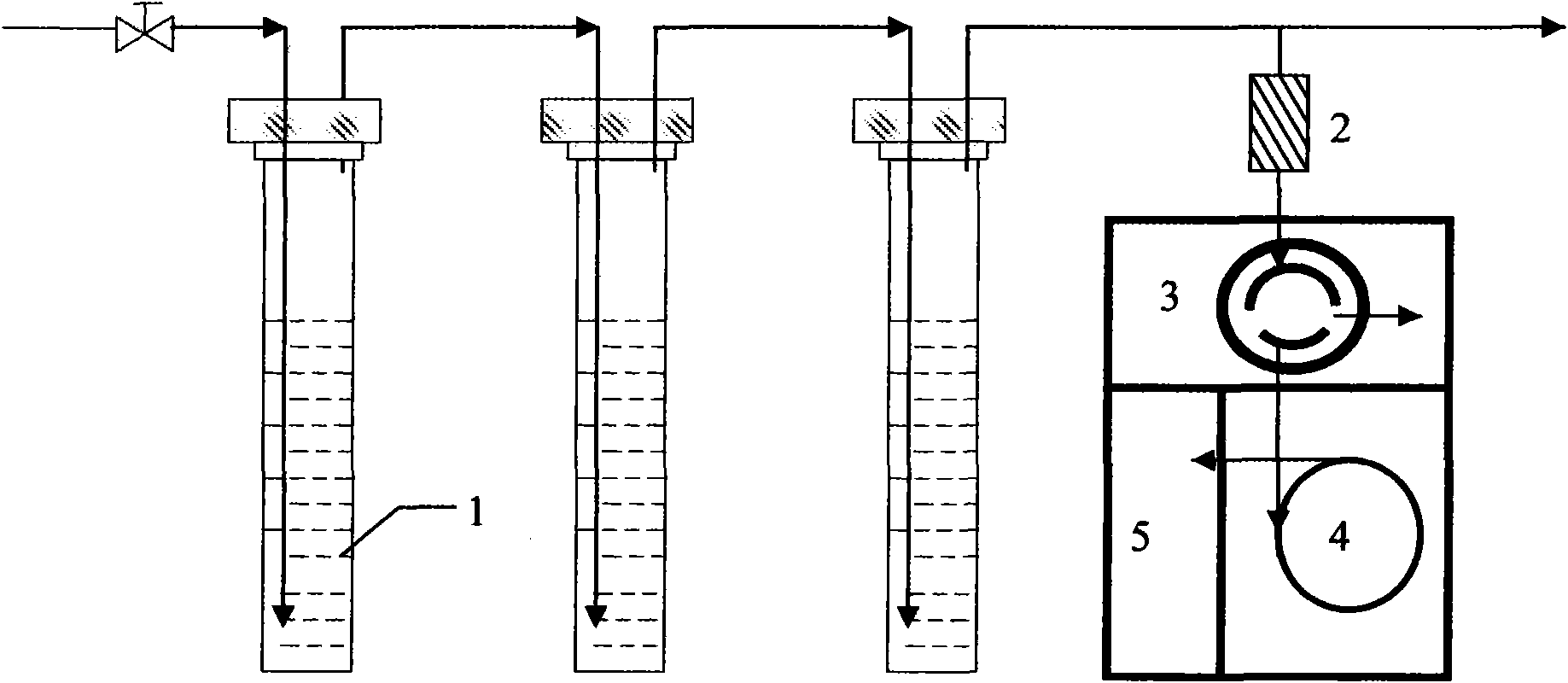

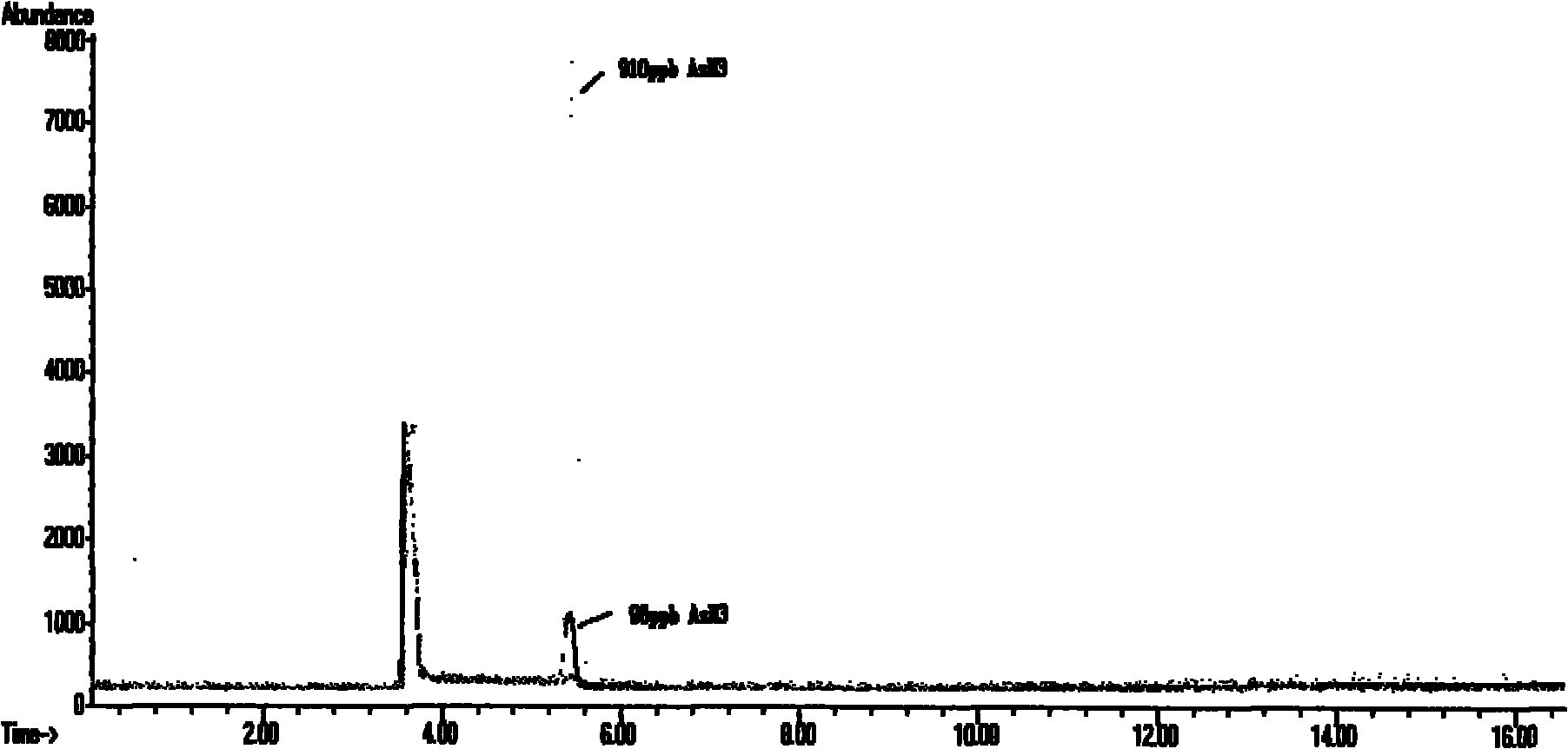

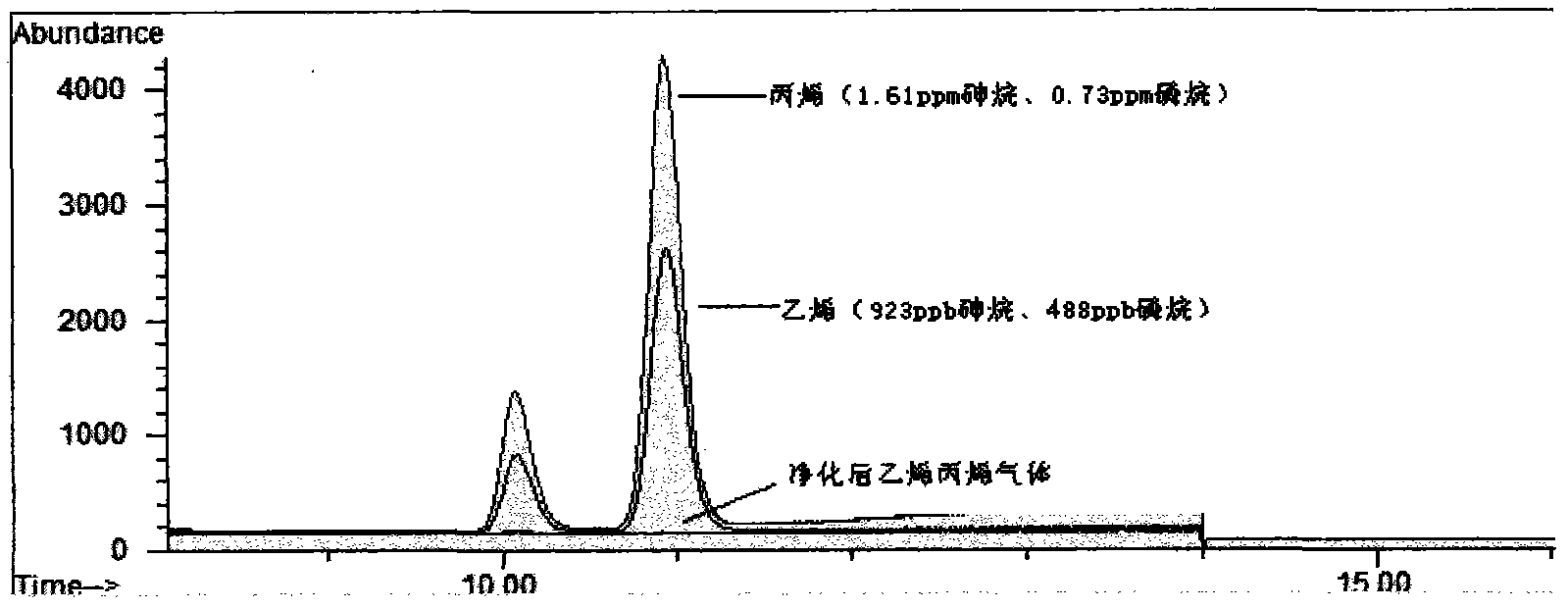

Copper salt absorption liquid for desorbing arsenic hydride from ethane and propene in gas phase and application thereof

ActiveCN102311301AHigh sensitivityMonitoring Arsine ContentComponent separationAbsorption purification/separationChromatographic separationGas phase

The invention relates to a copper salt absorption liquid for desorbing arsenic hydride from ethane and propene in gas phase and an online monitoring system. The absorption liquid is composed of the mixed liquid of bromine water, hydrogen peroxide, copper salt and inorganic acid. The online monitoring system comprises a sampling system, a gas-phase chromatographic separation system and a mass spectrum analysis system, wherein a six-way valve of the sampling system is used for sampling continuously; and the gas-phase chromatographic separation system is used for separating the arsenic hydride from the ethane and the propene, and then the mass spectrum analysis system is used for monitoring quantitatively. The absorption liquid provided by the invention has the advantages of simple ingredient and low cost. The arsenic hydride in the ethane and the propene can be desorbed to a content of smaller than 30ppb. The online monitoring system has the advantages of high sensitivity, low limit of detection and capability of rapidly reflecting the absorbing and purifying effect of the absorption liquid.

Owner:CHINA PETROLEUM & CHEM CORP +1

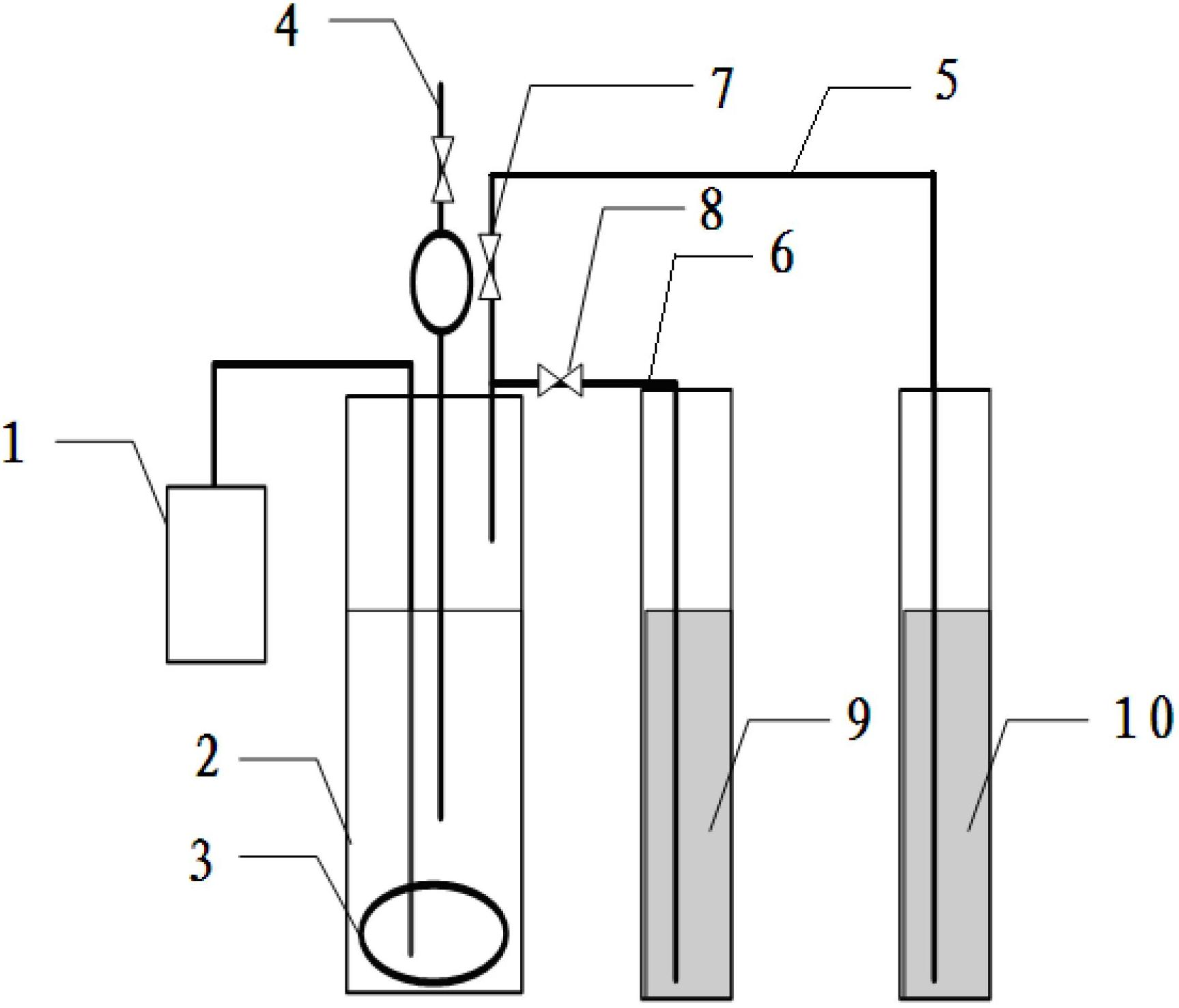

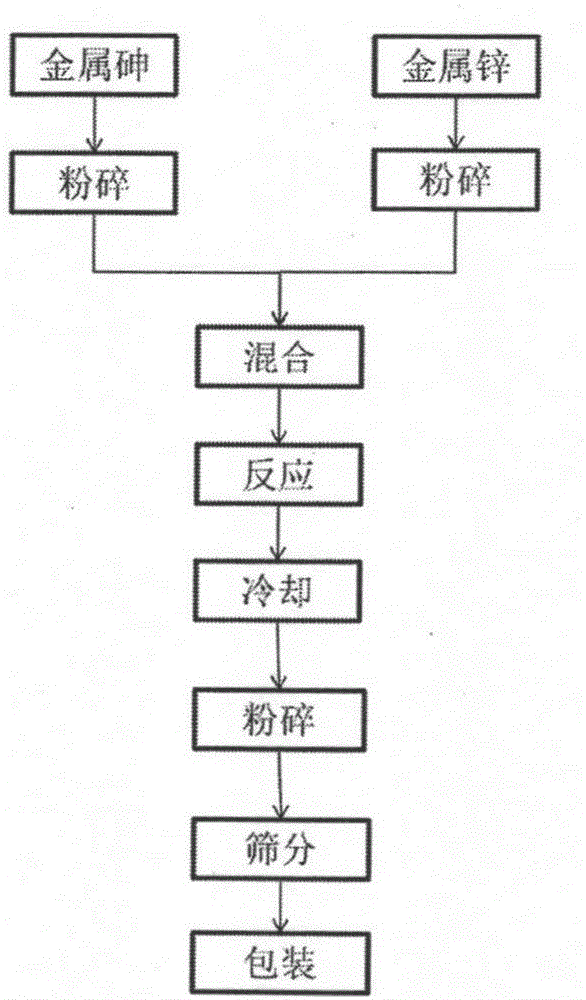

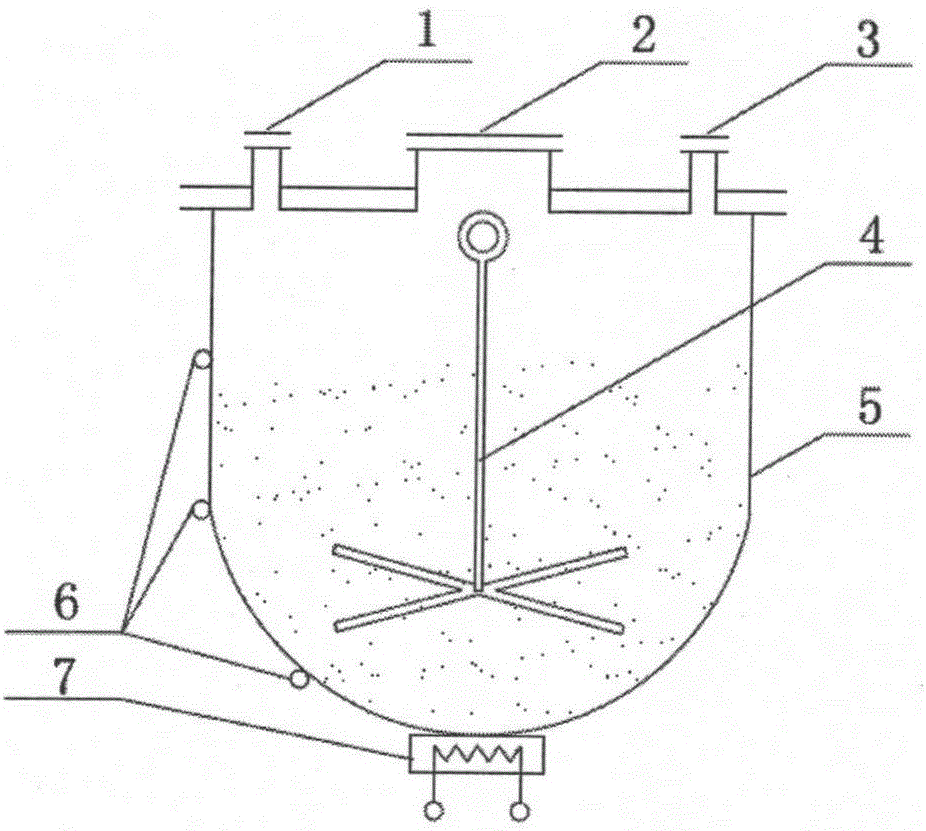

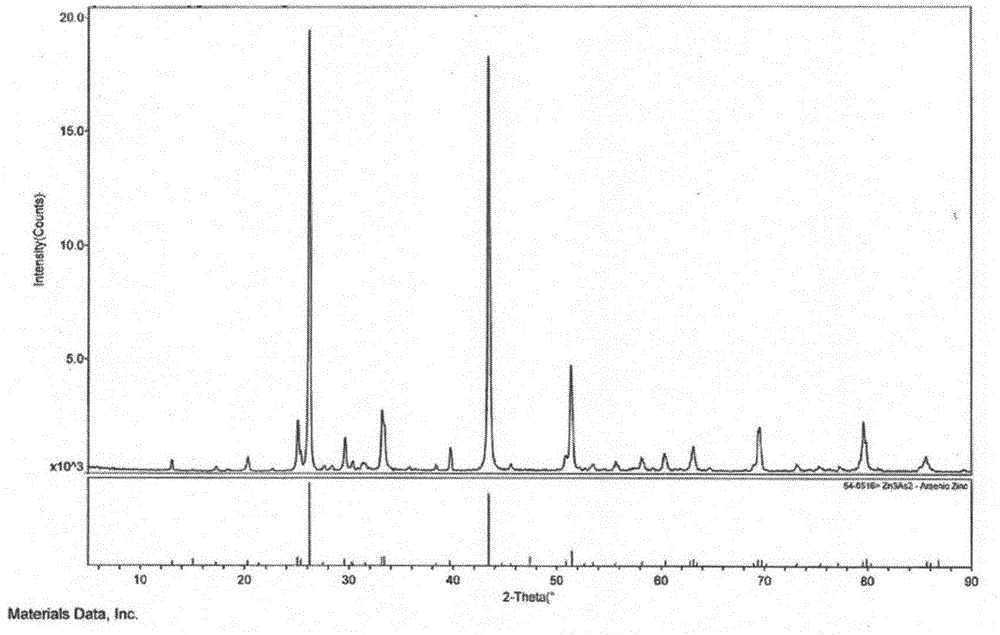

Highly-pure zinc arsenide preparation device and method

The invention provides a highly-pure zinc arsenide preparation device and method. The highly-pure zinc arsenide preparation method is characterized in that the highly-pure zinc arsenide preparation device is adopted, and the method comprises the following steps: crushing and mixing metal arsenic and metal zinc under the protection of nitrogen, and filling a closed reactor with the above obtained mixture from a raw material charging opening; triggering a reaction of the metal arsenic and the metal zinc in the reactor under the protection of nitrogen by heating of an electric heater, stopping heating after the reaction starts, and allowing heat regenerated in the reaction to make the reaction continuously goes on; and naturally cooling the above obtained reaction product under the protection of nitrogen after the reaction ends in order to obtain highly-pure zinc arsenide. Highly-pure nitrogen blowing is continuously adopted in the reaction process to remove impurities in order to obtain the highly-pure zinc arsenide product. Zinc arsenide with a tetragonal crystal structure is obtained through natural cooling after reaction ending, and is used for producing hydrogen arsenide gas as a raw material.

Owner:SHANGHAI ZHENGFAN TECH

Preparation and use method of rapid detecting agent for measuring arsenic in water body

ActiveCN106198416AAvoid wastingEasy to useColor/spectral properties measurementsSodium acetatePotassium borohydride

The invention relates to a preparation and use method of a rapid detecting agent for measuring arsenic in a water body, and belongs to the technical field of environment monitoring. The rapid detecting agent comprises arsenic detecting powder I, arsenic detecting powder II and arsenic detecting pieces III, wherein the arsenic detecting powder I is prepared by evenly mixing potassium borohydride / sodium borohydride, sodium acetate and copper sulfate according to the ratio of (5-15):2:1, the arsenic detecting powder II is prepared by evenly mixing silver sulfate, ammonium bisulfate, polyvinyl alcohol and sodium sulfate according to the ratio of (0.1-1):(2-10):(0.1-0.5):(20-80) and grinding the materials into powder, and the arsenic detecting pieces III are prepared by evenly mixing, drying and tabletting phosphoric acid and monopotassium phosphate according to the ratio of 1:(5-20). The arsenic content can be obtained by putting a to-be-detected water sample in a generation bottle of an arsenide hydrogen generation device, adding the arsenic detecting powder I, dissolving the arsenic detecting powder II in Baijiu, pouring the liquid in an absorption pipe and conducting measuring through a chromometer or spectrophotometer. The rapid detecting agent is simple in process, stable in quality and safe and convenient to carry, transport and use. The method is suitable for rapid field or site detection of trace arsenic in surface water, underground water, domestic sewage, industrial wastewater and other water bodies.

Owner:TONGJI UNIV

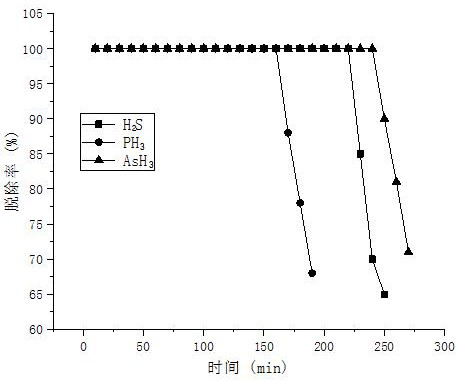

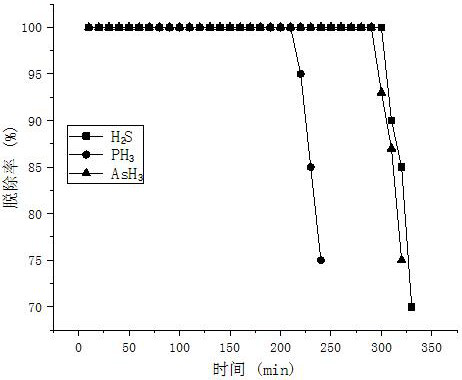

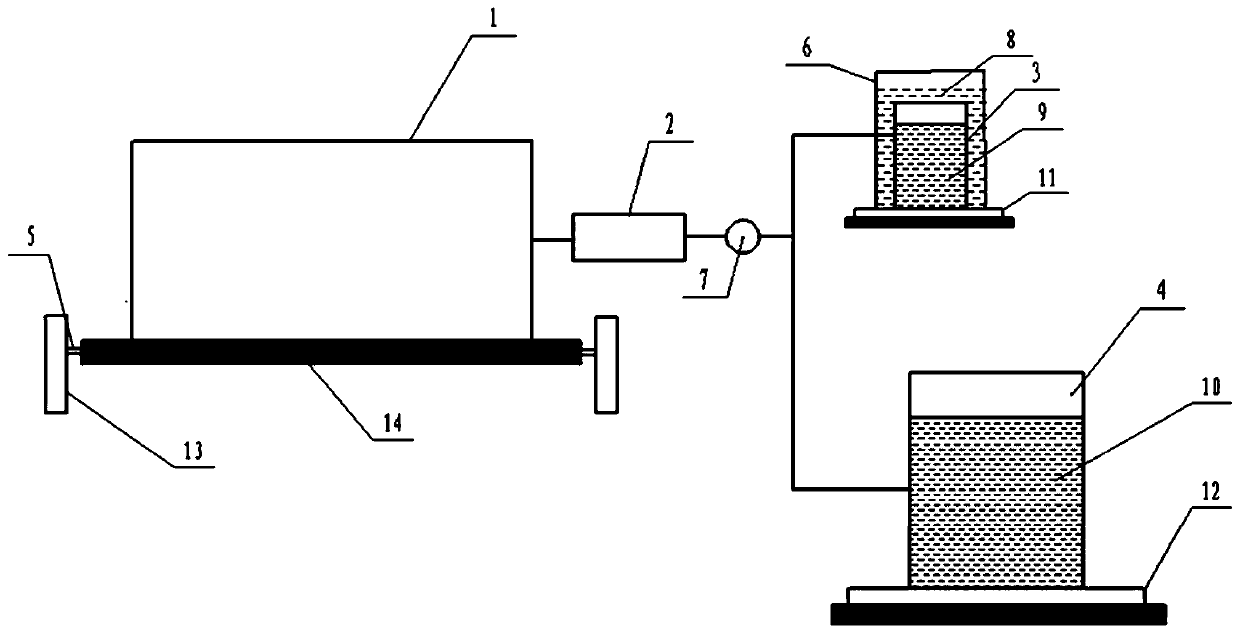

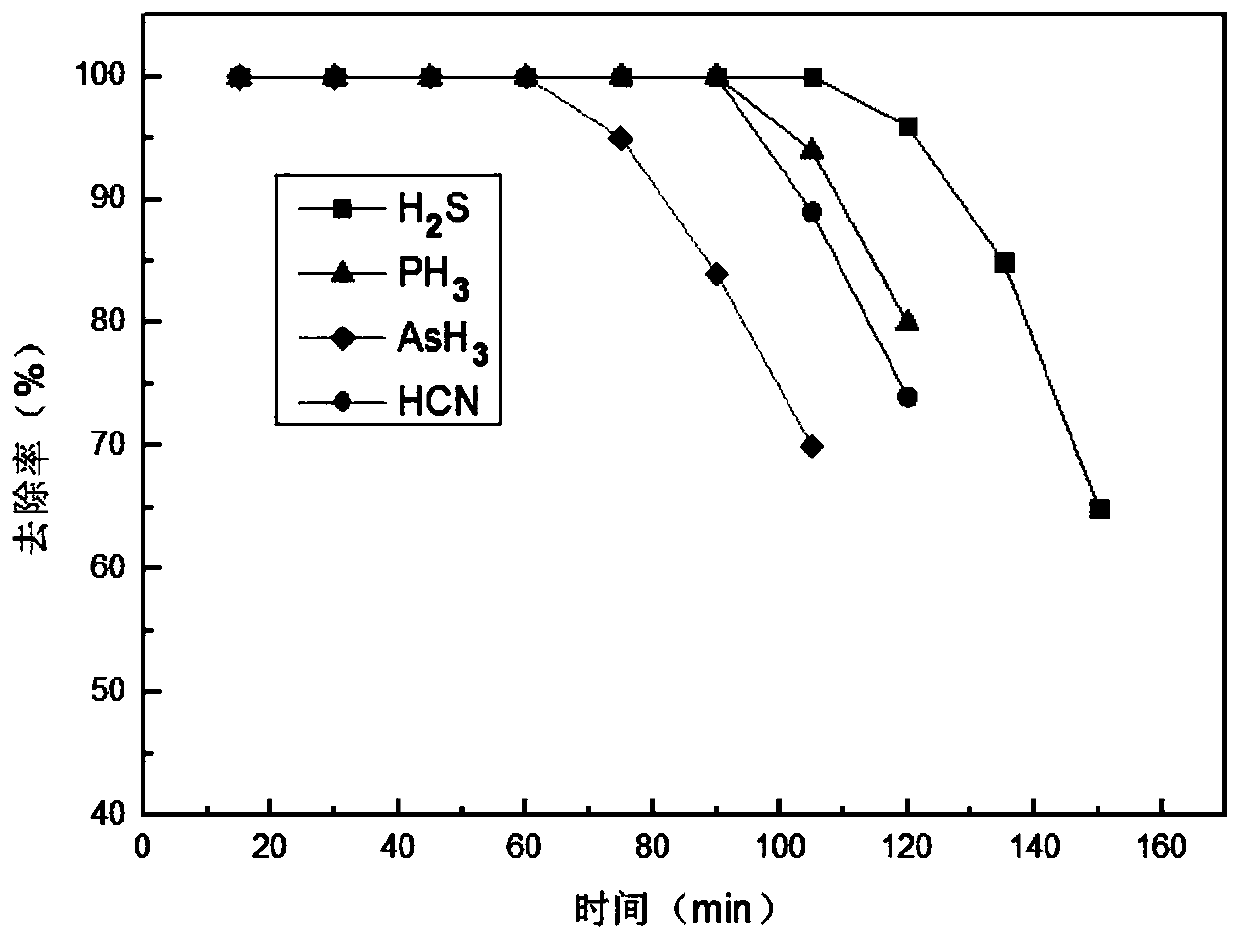

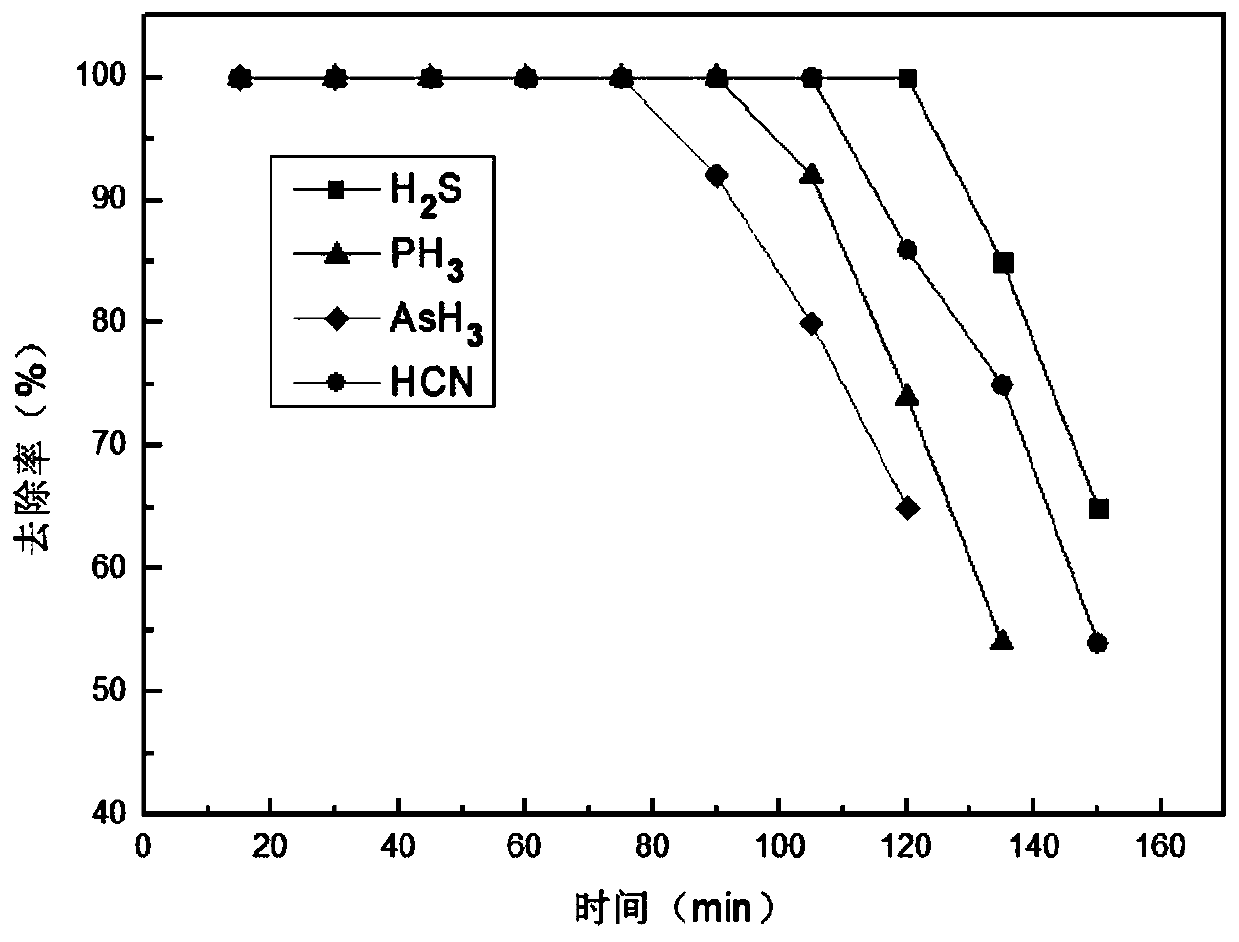

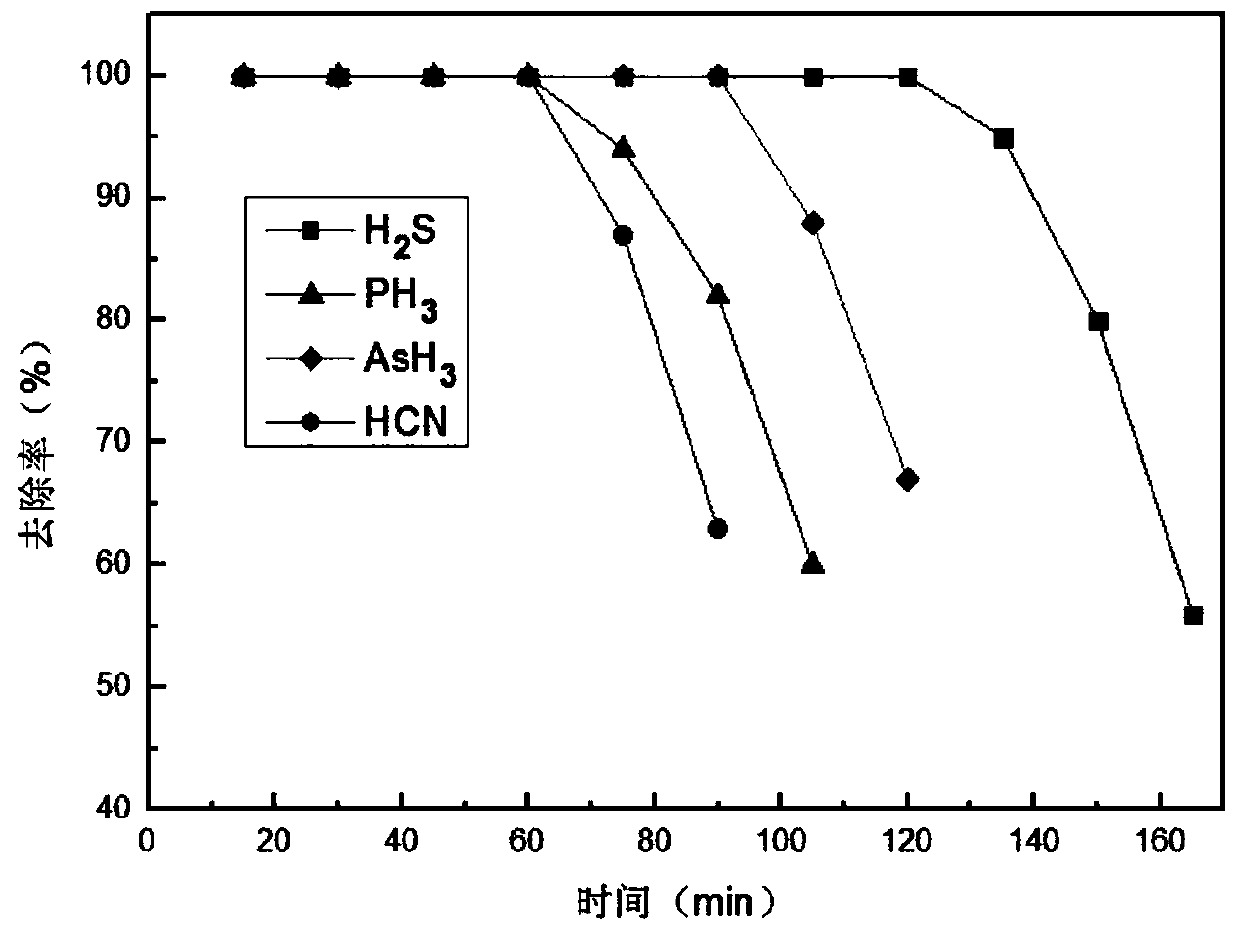

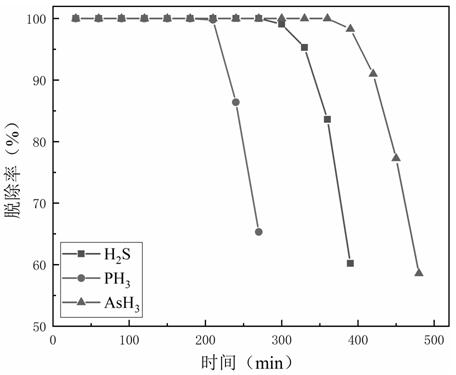

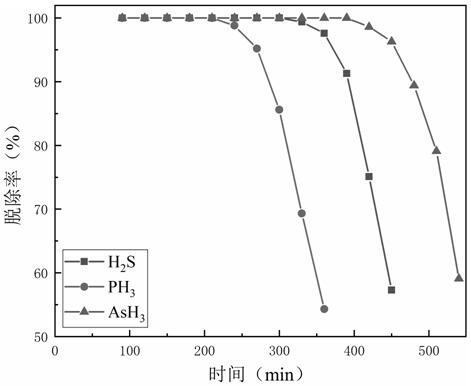

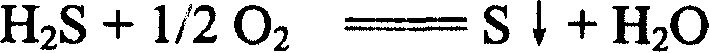

Application of plasma modified catalyst in removal of hydrogen sulfide, hydrogen phosphide and arsenic hydride

InactiveCN112657558AEasy to prepareReduce energy consumptionOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationPtru catalystPhysical chemistry

The invention discloses an application of a plasma modified catalyst in removal of hydrogen sulfide, hydrogen phosphide and arsenic hydride, which comprises the following steps: introducing a gas containing hydrogen sulfide, hydrogen phosphide and arsenic hydride into a reactor filled with the plasma modified catalyst, and removing hydrogen sulfide, hydrogen phosphide and arsenic hydride at 60-90 DEG C; the MOFs generate more unsaturated metal active sites and a large number of active free radicals through low-temperature plasma discharge, and the prepared plasma modified catalyst is applied to removal of hydrogen sulfide, hydrogen phosphide and arsenic hydride, has a good removal effect at a low temperature, can be widely applied to simultaneous removal of H2S, PH3 and AsH3 in various gas sources. The method is suitable for industrial application and market promotion.

Owner:KUNMING UNIV OF SCI & TECH

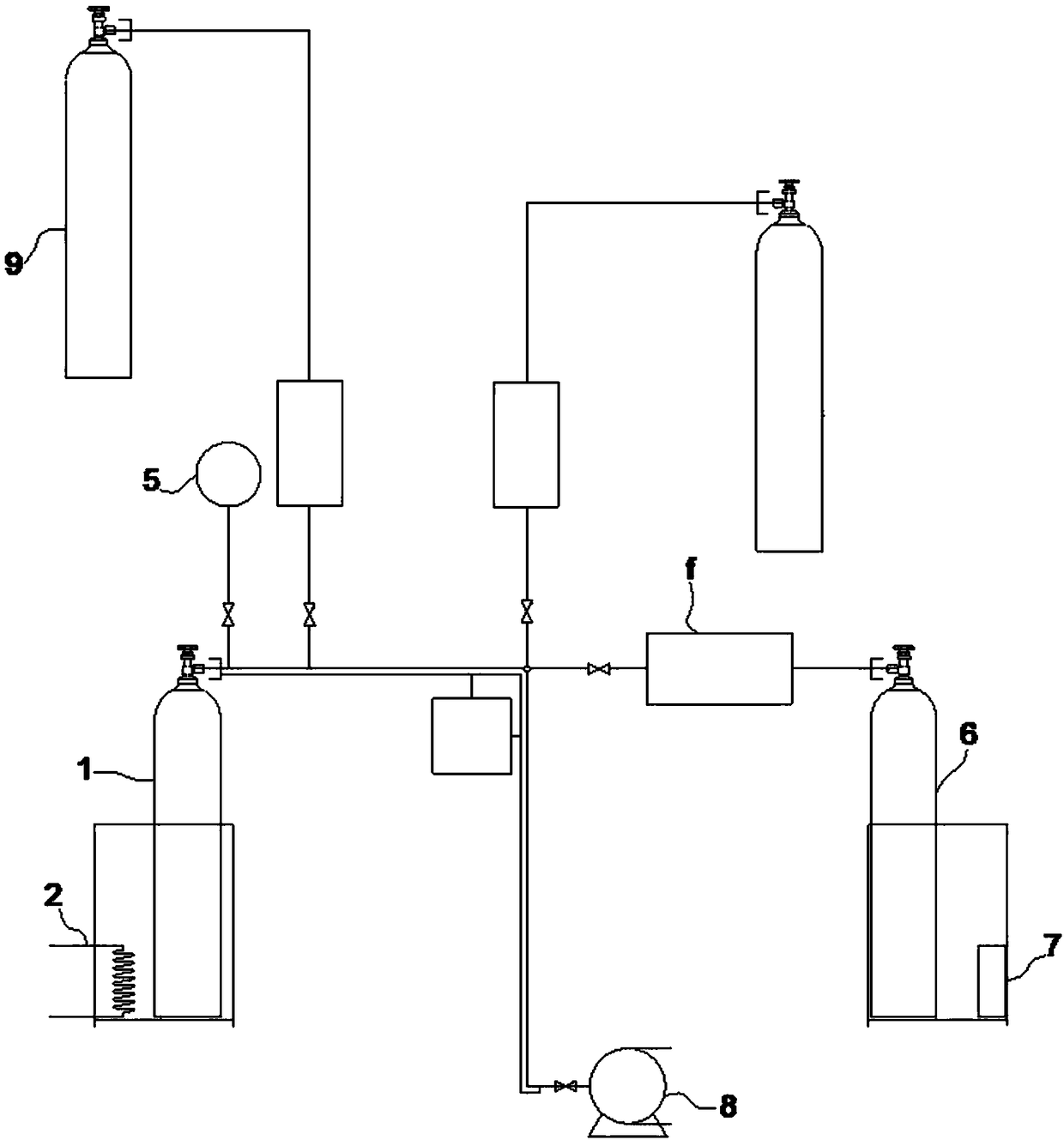

Preparation device and method for hydrogen arsenide gas standard substances in nitrogen

PendingCN109884218AGood time stabilityAvoid accidentsComponent separationMaterial analysis by electric/magnetic meansLiquid stateTotal nitrogen

The invention belongs to the field of development and preparation of gas standard substances, and particularly relates to a preparation device and method for hydrogen arsenide gas standard substancesin nitrogen. A cooling and liquid nitrogen gasification purging mode is used, so that gaseous hydrogen arsenide with concrete rank poison maintains a liquid state in the transferring process; the accident causing possibility due to leakage of the hydrogen arsenide is avoided; meanwhile, complete no-residue transfer is realized; meanwhile, used purging gas is diluent gas, so that the preparation result cannot be influenced; the total nitrogen gas consumption can be obtained in a mass comparator metering mode; and the precision is ensured. The method has the advantages that the operation is safe, convenient and fast; the precision is high; and in addition, the obtained hydrogen arsenide gas standard substances in nitrogen have high uniformity and stability.

Owner:SHANDONG NON METALLIC MATERIAL RES INST

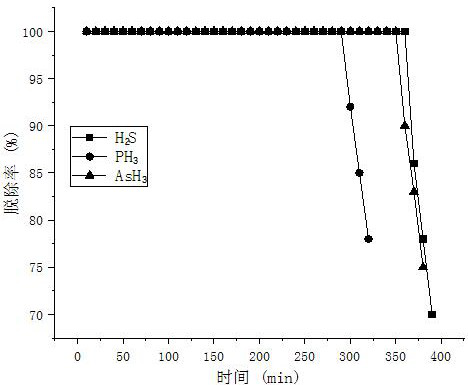

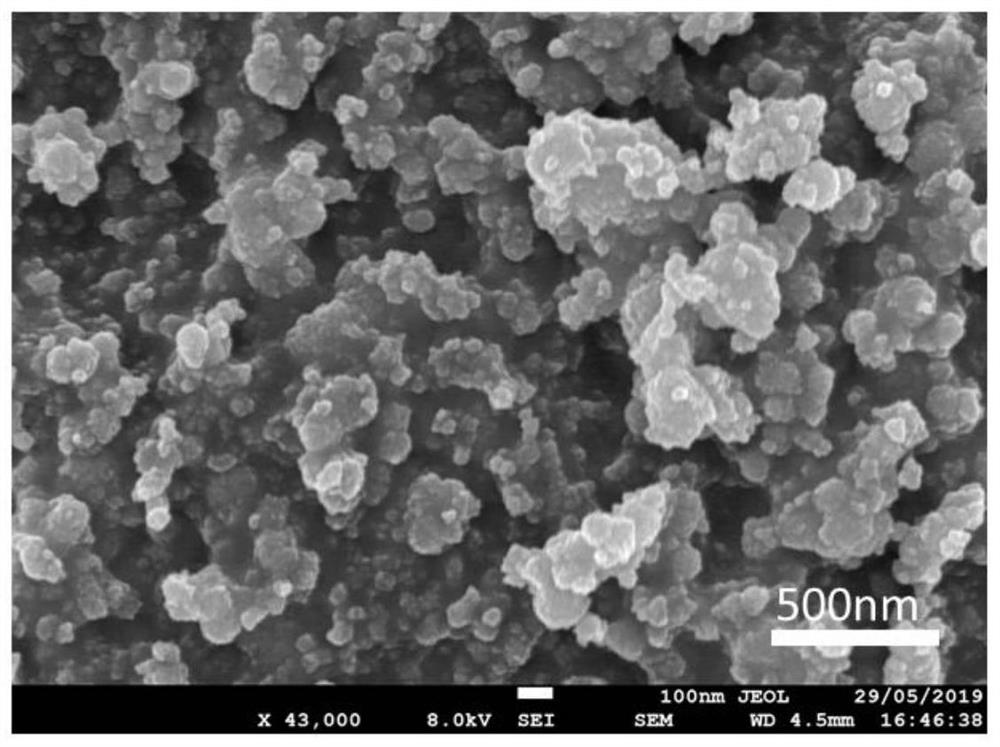

White carbon black core-shell structure catalyst and preparation method and application thereof

InactiveCN111450835AImprove performanceImprove conversion rateHeterogenous catalyst chemical elementsDispersed particle separationPtru catalystAtmospheric pollution

The invention provides a white carbon black core-shell structure catalyst and a preparation method and application thereof, and belongs to the technical field of air pollution control. According to the white carbon black core-shell structure catalyst provided by the invention, SiO2 is used as the core, and a CuO-CeO2-MgO compound is used as the shell. According to the invention, precipitated whitecarbon black and a plurality of metal salts are used as raw materials; the white carbon black particles are wrapped with oxides of copper, cerium and magnesium by using a coprecipitation method; andthe obtained core-shell structure catalyst is stable in performance, can be stably used in the atmosphere of coexistence of hydrogen sulfide, hydrogen phosphide, arsenic hydride and hydrogen cyanide,has a good effect of simultaneously removing various gases such as AsH3, HCN, H2S and PH3 in reductive industrial furnace tail gas, and has the advantages of stable structure, good adaptability, higher conversion rate and the like.

Owner:KUNMING UNIV OF SCI & TECH

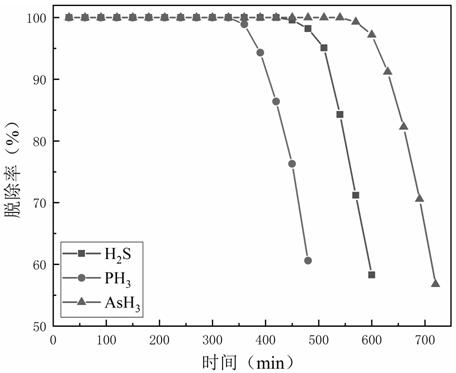

Method for removing hydrogen sulfide, hydrogen phosphide and arsenic hydride by using low-temperature plasma modified alumina-based catalyst

InactiveCN113457438AAdjustable surface acidity and alkalinityLarge specific surface areaCatalyst carriersGas treatmentPtru catalystRotary evaporator

The invention discloses a method for removing hydrogen sulfide, hydrogen phosphide and arsenic hydride by using a low-temperature plasma modified alumina-based catalyst, and belongs to the field of material preparation and air pollution prevention and control. The method comprises the following steps: immersing alumina particles into ultrapure water, carrying out ultrasonic pretreatment, and drying; grinding the dried aluminum oxide particles into powder, carrying out metal loading on the aluminum oxide powder by adopting a rotary evaporator, drying, and then roasting the dried sample by using a microwave muffle furnace; tabletting, grinding and screening the roasted sample, and modifying under a certain condition by using low-temperature plasma. Compared with a traditional modification method, the low-temperature plasma modification catalyst can achieve high-functionalization and high-added-value surface treatment, equipment is simple, the operation process does not have harmful effects on the environment, the modification time is short, and the method is an energy-saving and pollution-free clean type environment-friendly technology; and the alumina-based catalyst modified by the low-temperature plasma has a good removal effect on hydrogen sulfide, hydrogen phosphide and arsenic hydride gas.

Owner:KUNMING UNIV OF SCI & TECH

Method for recovering indium from indium-contained materials in zinc smelting

The invention discloses a method for recovering indium from indium-contained materials in zinc smelting. The method comprises the following steps: (A) the reduction leaching is performed on the indium-contained materials under microwave conditions to obtain reduction leaching liquid; (B) under ultrasonic conditions, limestone powder emulsion is used for performing neutralization, hydrolysis and indium sinking on the reduction leaching liquid to obtain iron-contained solution and indium-enriched first gypsum slag; (C) under acid conditions, indium in the first gypsum slag is leached out to obtain indium-enriched solution and second gypsum slag; (D) Cu2+ in the indium-enriched solution is reduced as a simple substance Cu, and Fe3+ is reduced as Fe2+ to obtain reduced liquid; and (E) charcoalpowder is used for purifying and decontaminating the reduced liquid to obtain purifying liquid; and the purifying liquid is extracted. The method has the advantages of generation of no hydrogen arsenide and no emulsifying phenomenon and high recovery rate of indium; and under microwave and ultrasonic effects, ions can be quickly exchanged to accelerate the reaction speed.

Owner:欧艳

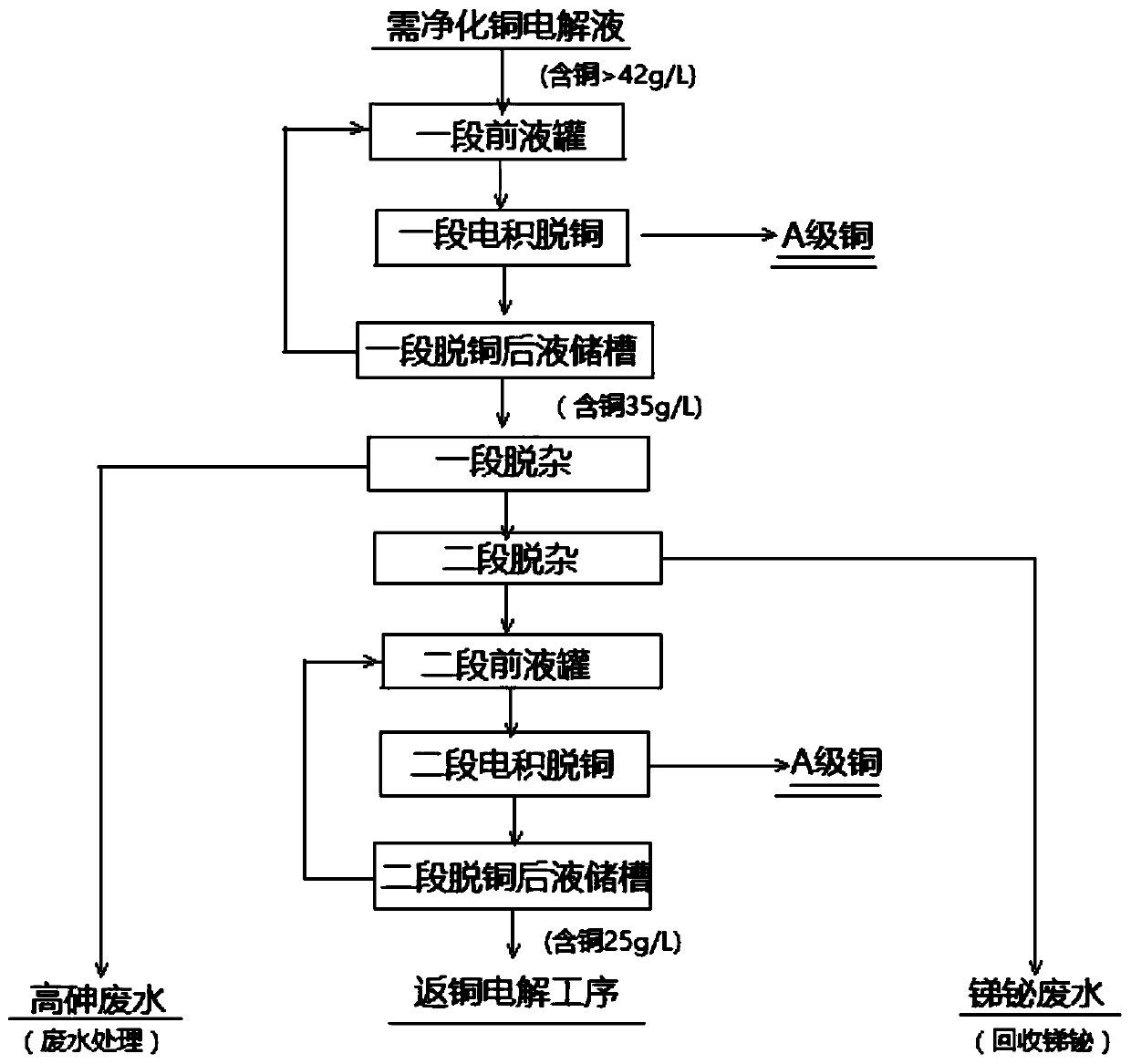

A method for purifying copper electrolyte by two removals and two accumulations

ActiveCN109536992BAvoid it happening againGood arsenic removal effectPhotography auxillary processesProcess efficiency improvementElectrolytic agentSlag

The invention provides a method for purifying a copper electrolyte through two-stage decoppering and two-stage electrodeposition. The method comprises the following steps that S1, first-stage electrodeposition decoppering is carried out on a to-be-purified copper electrolyte of which the concentration of cooper ions is greater than 42 g / L, so that the concentration of the cooper ions is reduced to29-35 g / L, and A-grade copper and a first-stage decoppered liquid are obtained respectively; S2, first-stage impurity removal is carried out on the first-stage decoppered liquid by adopting an arsenic precipitating agent, the arsenic precipitating agent is an antimony hydroxide hydrate, and first-stage impurity removal slag and a first-stage liquid after impurity removal are obtained respectively; S3, second-stage impurity removal is carried out on the first-stage liquid after impurity removal, so that the concentration of antimony and bismuth is reduced, and a second-stage liquid after impurity removal is obtained; S4, second-stage electrodeposition decoppering is carried out on the second-stage liquid after impurity removal, and a second-stage decoppered liquid of which the concentration of A-grade copper and copper ions is less than 25 g / L is obtained respectively. The method for purifying the copper electrolyte through the two-stage decoppering and two-stage electrodeposition hasthe advantages that it can be ensured that the quality of electro-deposited copper meets an A-class copper standard, the generation of arsenic hydride is avoided, the working environment is better, the impurity removal energy consumption is low, and the running cost is low.

Owner:YANGGU XIANGGUANG COPPER

Method for measuring arsenic by iodine solution absorption method

InactiveCN101788495BMeet the content rangeMeet the actual productionMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsMolybdenum bluePollution

The invention discloses an accurate and reliable method for measuring arsenic by an iodine solution absorption method, which solves the problem that the traditional method produces poisonous waste liquor. In a H2SO4 medium greater than 3.6N, Zn reacts with an acid to produce nascent activated hydrogen; in the presence of KI and acidic SnCl2, As<5+> is reduced into As<3+>, and the trivalent arsenic reacts with the nascent activated hydrogen to produce hydrogen arsenide gas; and the hydrogen arsenide gas is absorbed by an iodine solution and is oxidized into quinquevalent arsenic. In a 0.25 equivalent sulfuric acid medium, the quinquevalent arsenic reacts with ammonium molybdate to produce yellow heteromolybdoarsenic acid. The heteromolybdoarsenic acid is reduced into arsenic molybdenum blue by hydrazine sulfatefor for colorimetric determination. The method for measuring arsenic by iodine solution absorption and the colorimetric determination of the arsenic molybdenum blue is more suitable for the analysis of as in raw materials for copper smelting and semi-finished products of matte anode copper; moreover, the use of poisonous and hazardous reagents is avoided, and environment pollution is reduced.

Owner:BAIYIN NONFERROUS GROUP

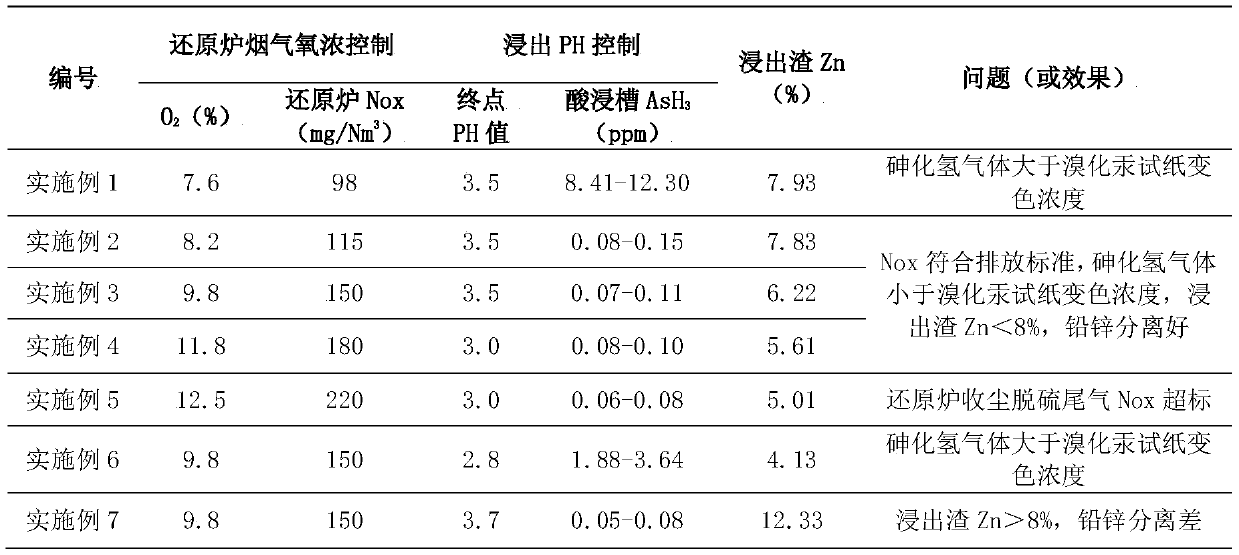

Method for inhibiting arsenic hydride gas during sulfuric acid leaching of high-arsenic-lead-zinc smoke dust

ActiveCN111363928AEasy to separatePrevent escapeProcess efficiency improvementMaterials scienceClean water

The invention relates to a method for inhibiting arsenic hydride gas during sulfuric acid leaching of high-arsenic-lead-zinc smoke dust produced by a lead reduction furnace, and belongs to the technical field of nonferrous metallurgy. The method comprises the following steps that a secondary tuyere is formed in an ascending section of the reduction furnace, air is continuously blown in, and the oxygen content in flue gas is controlled, so that volatile arsenic, lead, zinc steam and other metal steam are oxidized, and the single mass of metal in the smoke dust is controlled; and the high-arsenic-lead-zinc smoke dust is pulped through using clear water, leaching is carried out through using only one section of weak acid, the concentration of added dilute acid, the leaching process and an endpoint pH value are controlled, and after solid-liquid separation is carried out on a leached ore pulp, zinc is recovered from a filtrate, and filter residues are returned to an intensified smelting furnace to recover lead. By means of the method, the arsenic, the zinc and the like in the high-arsenic-lead-zinc smoke dust can be oxidized completely, the NOx content of dust-collected and desulfurized tail gas meets emission standard, the high-concentration arsenic hydride gas, formed by a small amount of metal elementary substances wrapped by metal oxides in the smoke dust and the leached arsenic, can be prevented from escaping, the content of Zn in the filter residues is smaller than or equal to 8.00%, and the zinc and the lead are well separated.

Owner:YUNNAN HONGCHI RESOURCE INTEGRATION UTILIZATION CO LTD

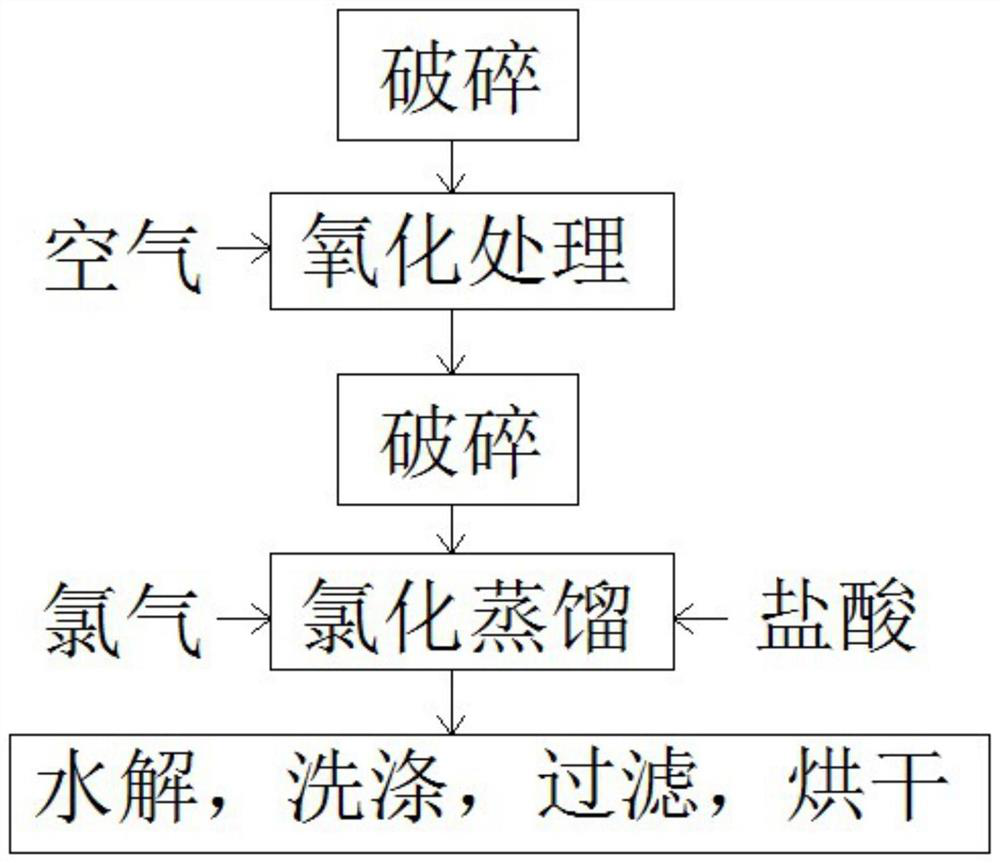

Method for recovering germanium from copper-lead-zinc-arsenic-germanium materials

InactiveCN113403488AFully oxidizedReduce production pollutionGermanium dioxideProcess efficiency improvementDistillationWater chlorination

The invention discloses a method for recovering germanium from a copper-lead-zinc-arsenic-germanium material. The method specifically comprises the following steps of 1, crushing the copper-lead-zinc-arsenic-germanium materials, adding an oxidizing agent, and uniformly mixing to obtain a mixture; 2, carrying out oxidation treatment on the mixture obtained in the step 1; 3, crushing the metal oxide obtained in the step 3; 4, mixing the crushed metal oxide with hydrochloric acid, performing chlorination distillation, condensing and collecting to obtain germanium tetrachloride; and 5, hydrolyzing, washing, filtering and drying the germanium tetrachloride to obtain crude germanium dioxide. The production pollution is small, the arsenic hydride generation condition is destroyed, hydrogen and arsenic hydride gas do not exist, the harm is reduced, and during heating oxidation, four-section temperature rising type heating is adopted, so that elements in the materials are fully oxidized.

Owner:YANGZHOU NINGDA NOBLE METAL CO LTD

Passivation treatment process for cylinders of electronic grade arsine, phosphine and their mixture gases

ActiveCN106185850BNo reduction in purityArsenic/antimony hydridesSolid state diffusion coatingVacuum pumpingMetallurgy

Owner:HEFEI ZHENGFAN ELECTRONICS MATERIAL

Method for purifying copper electrolyte with minimal chemical reacting dose

The invention relates to a method for purifying copper electrolyte with minimal chemical reacting dose, which belongs to the technical field of wet-process metallurgy. High-purity cathode copper, crude copper sulphate, black copper and nickel are obtained by the following steps of: removing copper by electro-deposition; evaporating and condensing liquid in vacuum after copper removal; crystallizing condensate after the copper removal to obtain copper sulfate; preparing electrolyte from which arsenic is removed; removing arsenic by the electro-deposition; and performing filter pressing on black copper slurry. Due to the adoption of the method of the invention, the electrolyte can be purified during copper electro-deposition and the arsenic is removed in the form of an arsenic-copper alloy, so that the production of hydrogen arsenide is controlled and the technical problem of realizing the purification of the copper electrolyte with the minimal chemical reacting dose is solved. The method has the advantages of capability of preventing invalid removal of the copper and effectively controlling the separation of polluting AsH3, simple operation, low energy consumption and suitability for copper electrolytic purification process.

Owner:HULUDAO ZINC IND CO LTD

Process for preparing high purity carbon monoxide gas by desulfurization of organic sulfur at low and normal temperature

ActiveCN100387692CProtection securityGuaranteed service lifeCombustible gas purificationPoly(ethylene glycol) dimethyl etherDesorption

The invention relates to a technology for removing organic sulfur at a low or normal temperature to prepare high-purity carbonic oxide gas. The method consists of gasifying the coke with carbon monoxide or carbon dioxide to prepare the raw gases including 10 % -99 % CO, 0.1 %-90 % CO2, 0.001 %-2 % O2, 50-9000ppm COS, 10-10000ppm H2S, through gas storage holder, after pressurization and pyrogenation, entering purification tower filled with puripreservatives of A and B to remove hazardous materials including nitrogen oxide, hydrogen arsenide, hydrogen phosphide, hydrogen chloride, hydrogen nitrile, oxides of sulfur and sulfureted hydrogen, entering tower for removing organic sulfur filled with sulfur carbonyl hydrolyst, hydrolyzing 85%-95% of sulfur carbonyl for conversion into sulfureted hydrogen, at 20-150 DEG C, with a pressure of 0.1-10 MP, in which the refined raw gases can be used by productions of fine chemical industry including downstream acetate, dimethyl formamide,dimethyl ether, toluene diisocyanate or methyl diphenylene diisocyanate. The technology converts 85 %-95 % of sulfur carbonyl into sulfureted hydrogen, can adopt routine wet desulfurization to replace polyethylene glycol dimethyl ether desulfuration,can carry out cycle utilization of carbon dioxide and sulfur carbonyl of decarburized desorption gases of polyethylene glycol dimethyl ether, and can carry out zero discharge of poison material of sulfur carbonyl, which is good for environmental conservation.

Owner:HAISO TECH +1

Purification method of indium back extraction solution

ActiveCN103014342BAvoid it happening againReduce consumptionProcess efficiency improvementIndiumPurification methods

Owner:ZHUZHOU SMELTER GRP

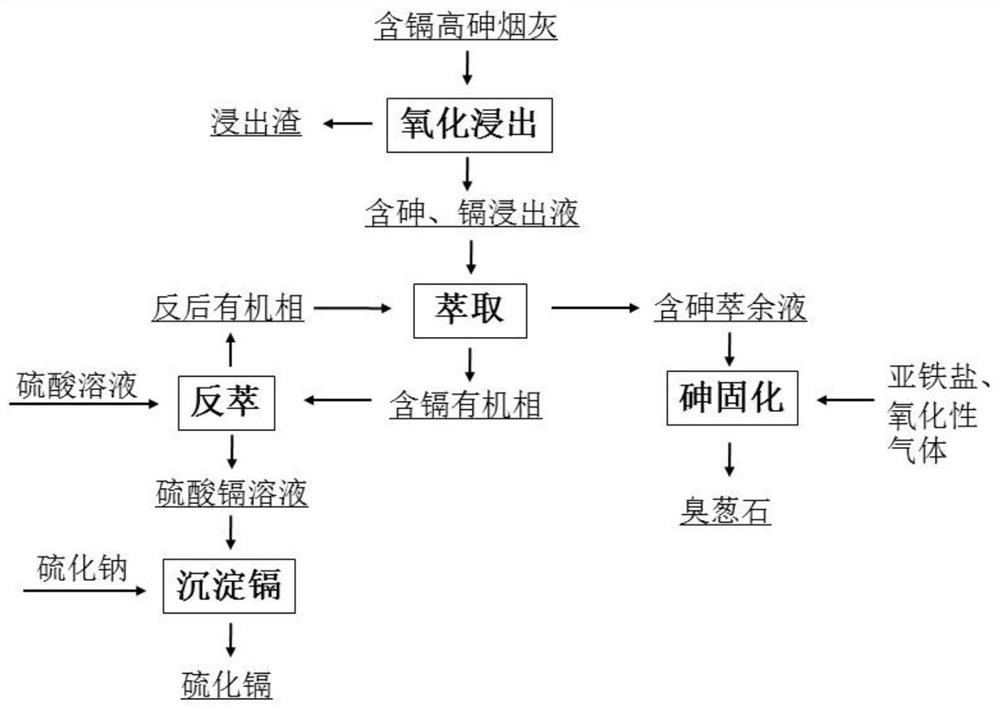

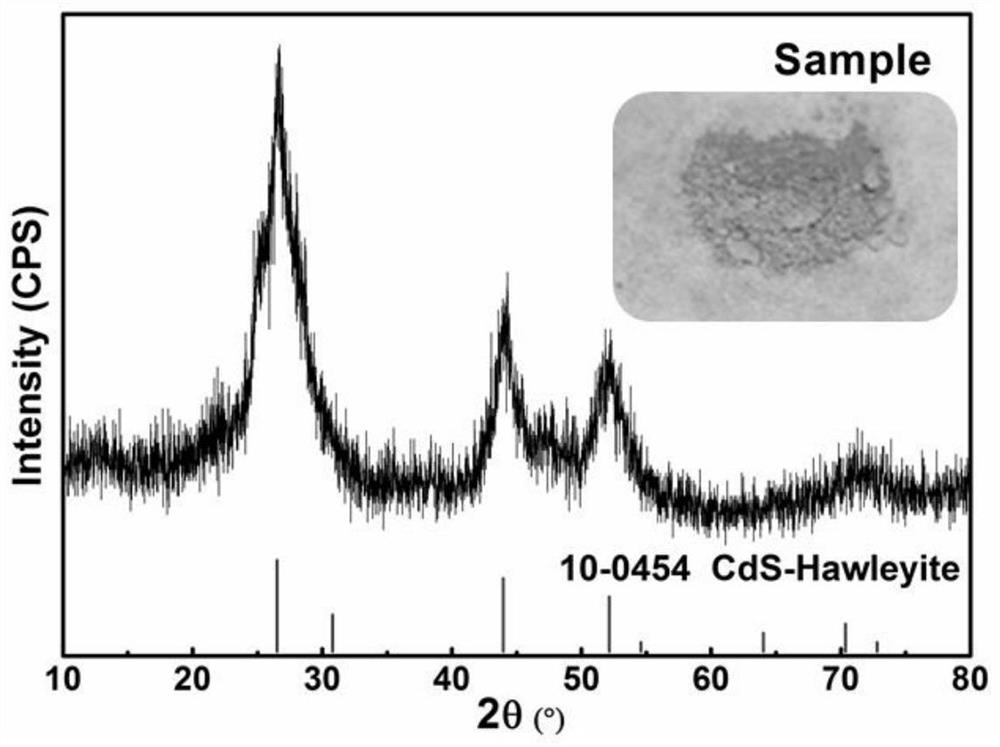

A method for recovering cadmium from cadmium-containing high arsenic soot

ActiveCN111041221BHardened securityCuring Handling SafetyIron compoundsProcess efficiency improvementFerrous saltsRaffinate

Owner:CENT SOUTH UNIV

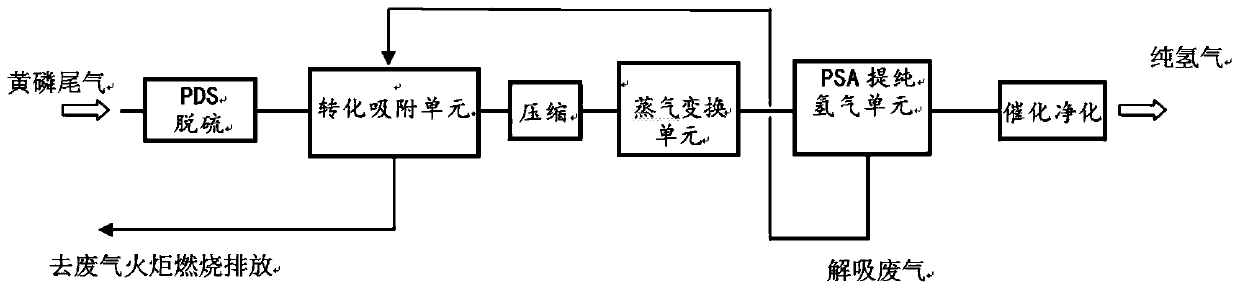

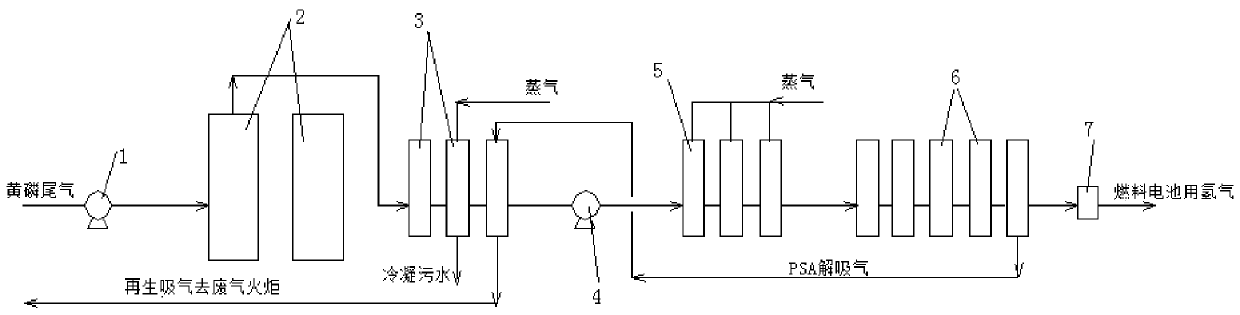

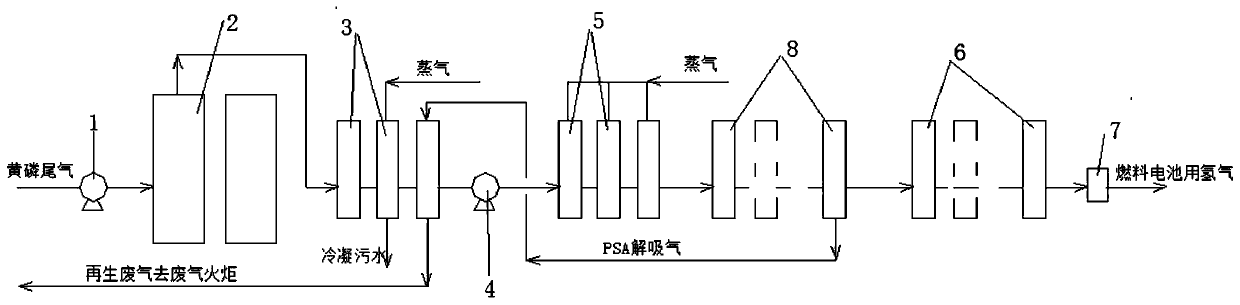

Method for preparing hydrogen for fuel cell from yellow phosphorus tail gas

PendingCN111362229AMeet the requirements of using hydrogenGas treatmentHydrogen separationOrganic sulfide compoundPtru catalyst

The invention belongs to the field of hydrogen extraction and particularly relates to a method for preparing hydrogen from industrial waste gas. The method is characterized in that yellow phosphorus tail gas sequentially passes through a PDS unit which is used for removing hydrogen sulfide and a part of sulfide in an organic form, a conversion and adsorption unit which is used for removing hydrogen phosphide, arsenic hydride, hydrogen sulfide and organic sulfide, a conversion unit which is used for reacting carbon monoxide in the yellow phosphorus tail gas with water vapor under the action ofa catalyst to generate hydrogen and carbon dioxide, and a PSA / H2 pressure swing adsorption hydrogen purification unit, thereby obtaining hydrogen; and the hydrogen passes through a catalytic purification unit so as to remove oxygen and trace hydrogen sulfide in the hydrogen, so the content of oxygen in the obtained hydrogen is lower than 5 ppm, the content of sulfide is lower than 0.004 ppm, the content of carbon dioxide is lower than 2 ppm, the content of water is lower than 5 ppm, the content of nitrogen is lower than 100 ppm, the content of hydrogen and impurities reaches the GB / T37244-2018standard, and the hydrogen meets requirements on hydrogen for the fuel cell.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Purifier for adsorbing arsenic hydride and hydrogen phosphide in olefin tail gas and preparation method thereof

ActiveCN102806065BReduce contentSimple ingredientsOther chemical processesDispersed particle separationPotassium manganateAtmospheric pollution

The invention relates to a normal-temperature purifier for adsorbing arsenic hydride and hydrogen phosphide in an olefin tail gas, belonging to the atmospheric pollution purification field. The purifier comprises following components in percentages by mass: 0.5-5% of potassium permanganate, 1-10% of soluble copper salt, 1-10% of soluble zinc salt and 75-97.5% of active carbon; the active carbon is a carrier; the potassium permanganate, and the soluble copper salt and the soluble zinc salt are active components. The preparation method of the purifier comprises following steps: (1), preparing a mixed water solution of the potassium permanganate, the soluble copper salt and the soluble zinc salt; (2), loading the potassium permanganate, the soluble copper salt and the soluble zinc salt on the active carbon carrier by a dipping method to obtain a carrier loaded with active metals; and (3), drying the carrier loaded with active metals in a drying medium to obtain the finished product purifier. The purifier disclosed by the invention has the advantages of simple component, low cost and low usage cost; after the purification, the content of arsenic hydride and hydrogen phosphide is less than 10ppb (volume percentage).

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com