Method for vulcanization, reducing oxidation and enrichment of low-grade material containing arsenic, indium and germanium

A low-grade, material technology, used in the improvement of process efficiency, instruments, optics, etc., can solve the problems of high production cost, difficult to handle arsenic slag, and difficult metal recovery, and achieve the effect of low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

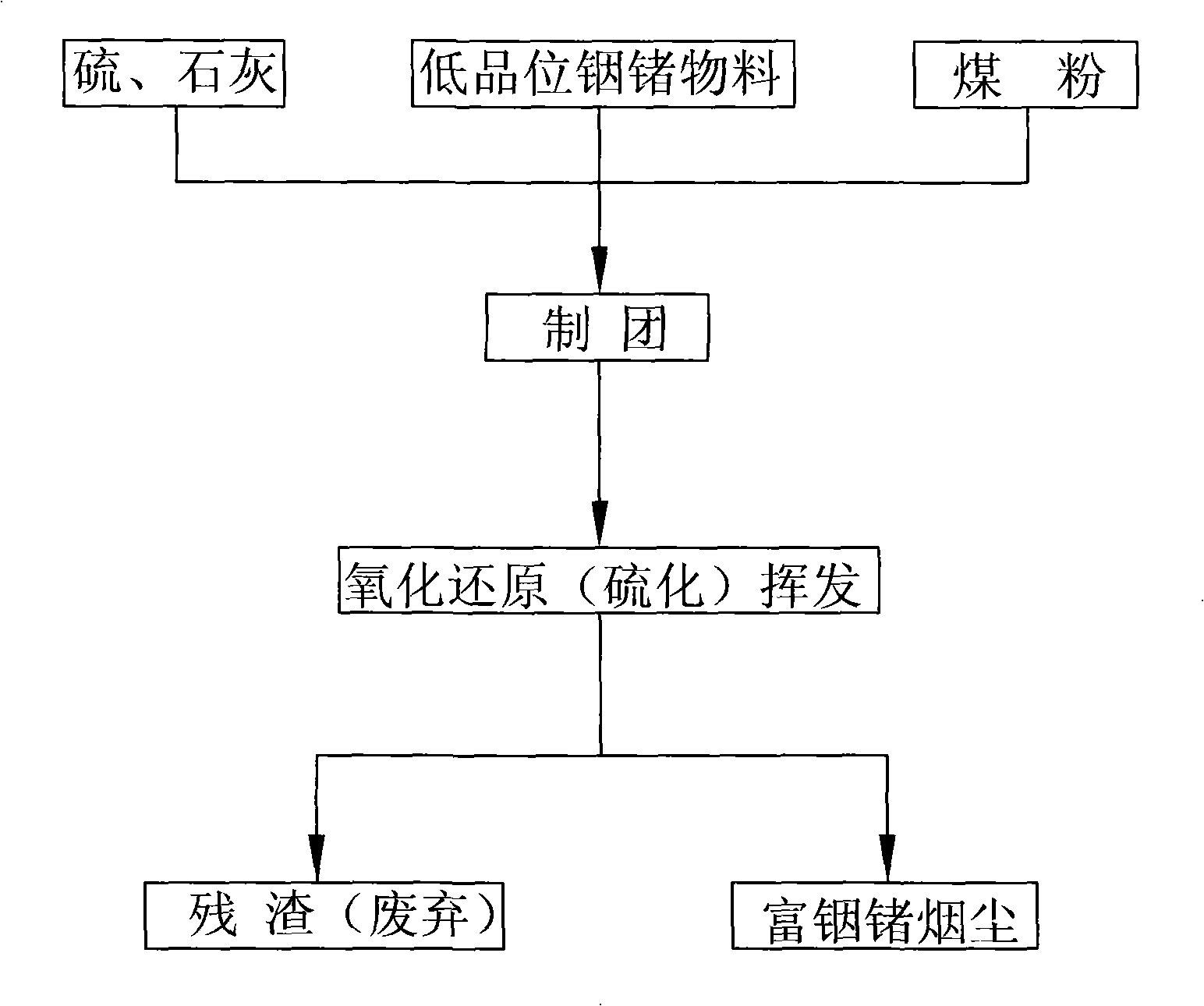

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0014] see figure 1 , a method for sulfidation and reduction-oxidation enrichment of low-grade materials containing arsenic, indium and germanium. The material containing indium, germanium, lead, zinc, and arsenic is mixed with a certain amount of elemental sulfur and anthracite powder, and the ratio is low-grade material containing arsenic, indium and germanium: lime : coal powder: sulfur = 100: 20: 10: 2, made into briquettes, at the same time adding a binder to make pellets, volatilized and volatilized in a shaft furnace, controlled temperature at 1000-1200 ° C, under a certain redox In the atmosphere, the volatilization time of vulcanization is 2 hours, the lead and zinc in the slag are below 2%, the content of indium and germanium can be reduced to about 30-300 g / ton, and the smoke and dust are leached when the end point of sulfuric acid is pH0. Substitution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com