Superfine ettringite, preparation method and application of superfine ettringite to cement-based grouting material

An ultra-fine calcium and alunite technology is applied in the application, preparation, and ultra-fine ettringite field of cement-based grouting materials, and can solve the problems that there is no ultra-fine such as nano-scale ettringite synthesis method and application, etc., To achieve the effect of easy industrial production, mild synthesis conditions, and promotion of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

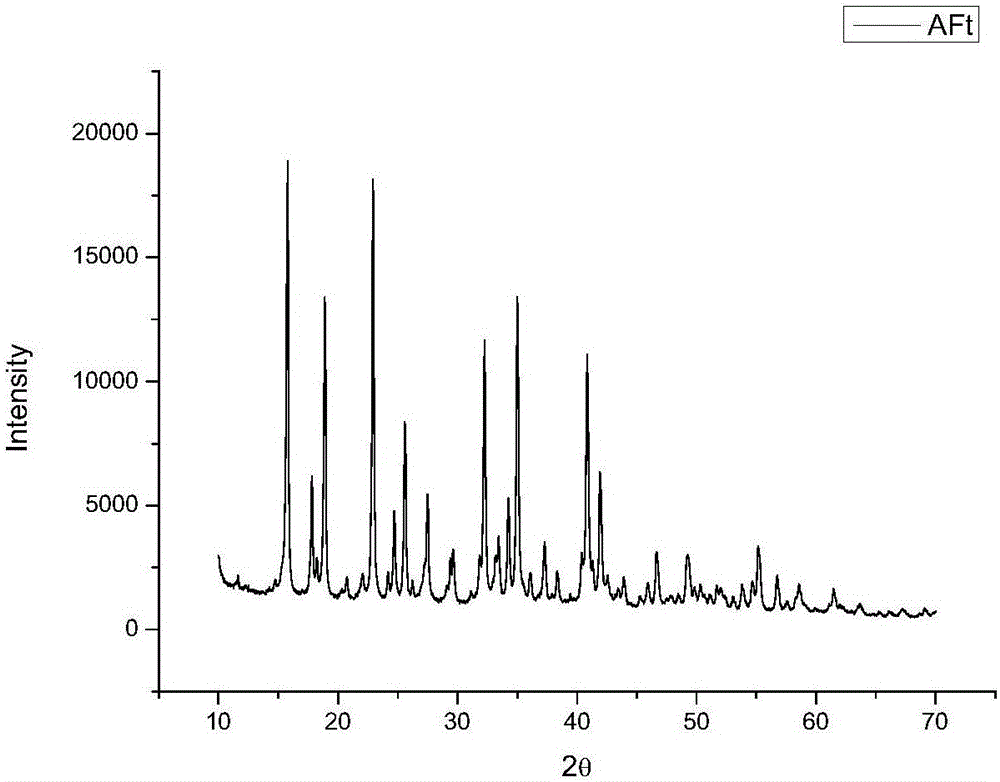

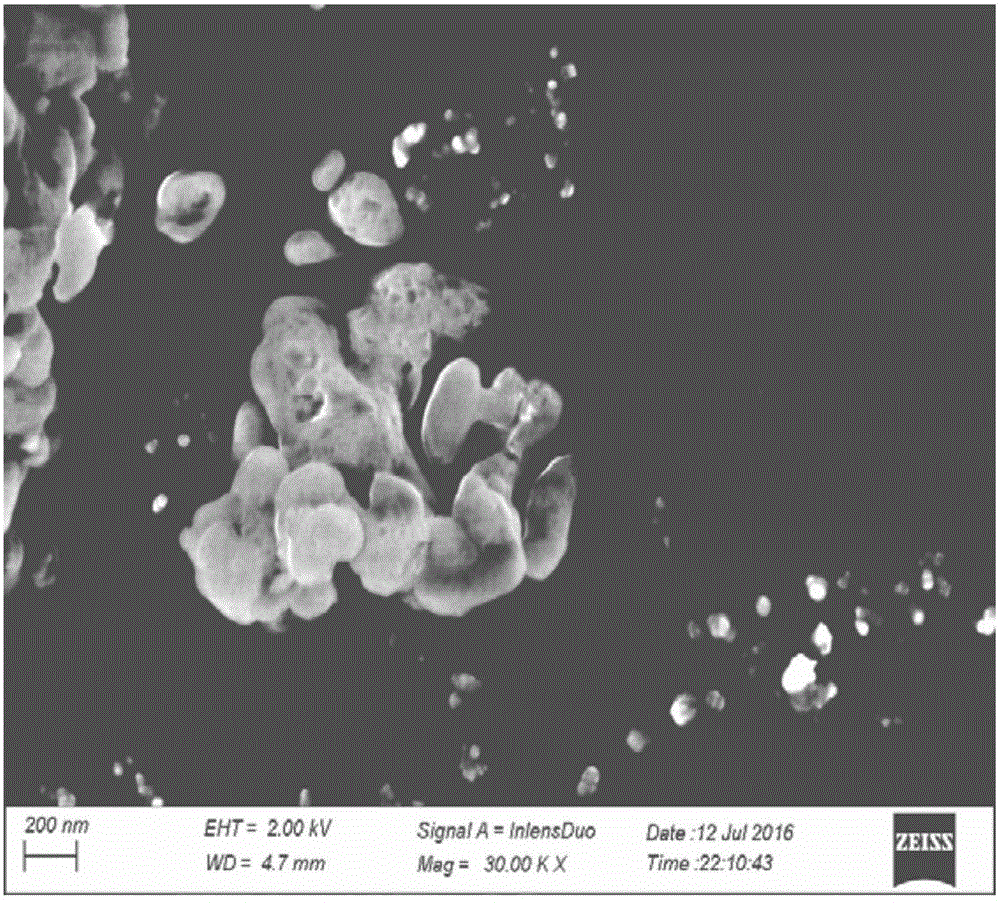

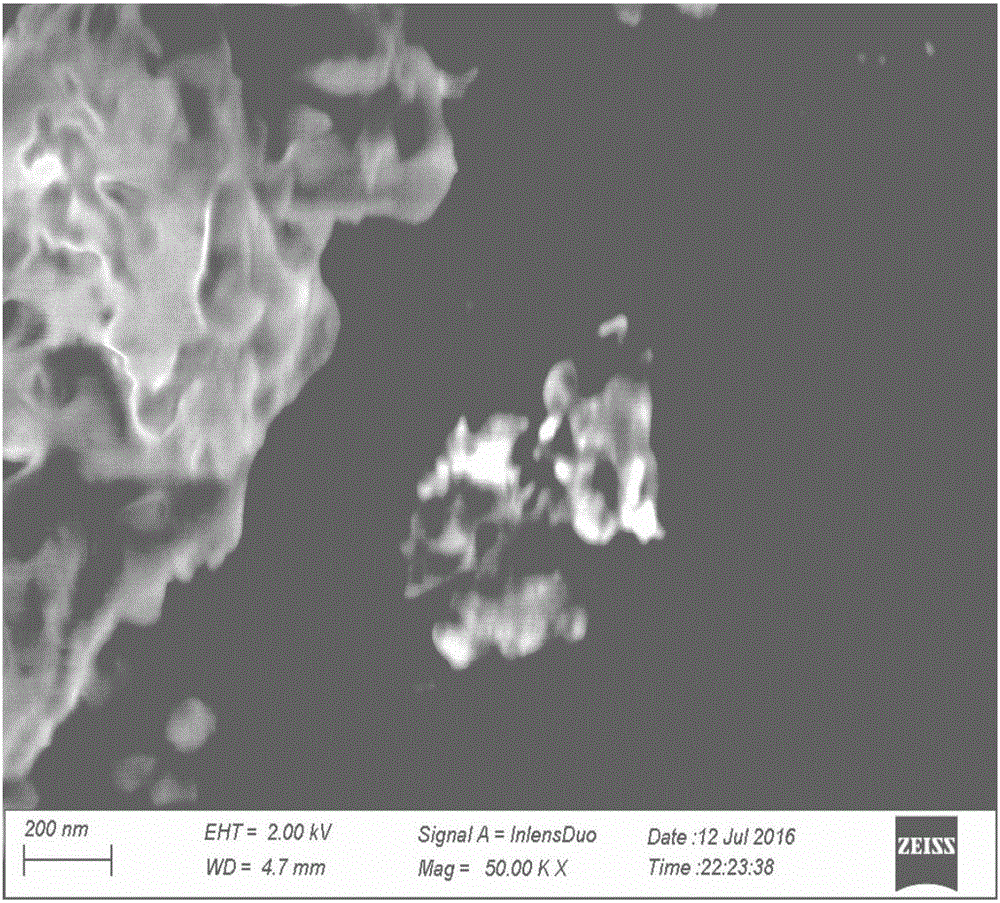

[0027] Preparation of ultrafine ettringite: weigh Ca(NO 3 ) 2 4H 2 O 35.423g (0.15mol) and polyhydroxy acid superplasticizer 0.3073g (0.5%) are dissolved in boiled and cooled deionized water, configured into 250ml salt solution; 2 (SO 4 ) 3 18H 2 O16.661g (0.025mol) was dissolved in boiled and cooled deionized water to form a 250ml salt solution; 12.0g (0.3mol) of NaOH was weighed and dissolved in boiled and cooled deionized water to form a 250ml alkaline solution; the three solutions Quickly mix in a full-return mixed explosion nucleation reactor, react for 2 minutes, then reflux and crystallize the slurry at 50°C for 10 hours, then centrifugally wash with hot water for 8 times until the pH value is about 7, and dry in an oven at 55°C , to obtain ultrafine ettringite, denoted as AFT-1.

[0028] Mix 75 parts of anhydrite, 20 parts of quicklime, 3 parts of ettringite (with a particle size of 0.005-2.0 μm), and 2 parts of naphthalene-based water reducer to obtain white mat...

Embodiment 2

[0031] Preparation of ultrafine ettringite: weigh Ca(NO 3 ) 2 4H 2 O 35.423g (0.15mol) and water reducer 0.9219g (1.5%) are dissolved in boiled and cooled deionized water, and are configured into 250ml salt solution; weigh Al 2 (SO 4 ) 3 18H 2 O 16.661g (0.025mol) was dissolved in boiled and cooled deionized water to be configured as 250ml salt solution; 12.0g (0.3mol) of NaOH was weighed and dissolved in boiled and cooled deionized water to be configured as 250ml alkali solution; the three solutions Quickly mix in a fully back-mixed explosive nucleation reactor, circulate vigorously for 2-3 minutes, then reflux and crystallize the slurry at 50°C for 10 hours, and then centrifugally wash with hot water (8-10 times) until the pH value is about 7. Dry in an oven at 55°C. Obtained superfine ettringite, which is denoted as AFT-2.

[0032] Mix 75 parts of anhydrite, 20 parts of quicklime, 3 parts of ettringite (with a particle size of 0.005-2.0 μm), and 2 parts of naphthalen...

Embodiment 3

[0036] Preparation of ultrafine ettringite: weigh Ca(NO 3 ) 2 4H 235.423g (0.15mol) of O and 1.5365g (2.5%) of water reducing agent were dissolved in boiled and cooled deionized water to configure 250ml salt solution; 2 (SO 4 ) 3 18H 2 O 16.661g (0.025mol) was dissolved in boiled and cooled deionized water to be configured as 250ml salt solution; 12.0g (0.3mol) of NaOH was weighed and dissolved in boiled and cooled deionized water to be configured as 250ml alkali solution; the three solutions Quickly mix in a fully back-mixed explosive nucleation reactor, circulate vigorously for 2-3 minutes, then reflux and crystallize the slurry at 50°C for 10 hours, and then centrifugally wash with hot water (8-10 times) until the pH value is about 7. Dry it in an oven at 55°C to obtain ultrafine ettringite, which is designated as AFT-3.

[0037] Mix 75 parts of anhydrite, 20 parts of quicklime, 3 parts of ettringite, and 2 parts of naphthalene-based water reducer evenly to obtain whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com