Composite concrete grinding-assistant reinforcing agent

A grinding aid enhancer and composite technology, applied in the field of composite grinding aids, can solve the problems of insignificant increase in strength, insignificant increase in yield, easy volatility, etc., so as to improve the utilization rate of waste and optimize the cement fineness gradation. , the effect of improving the dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A kind of composite cement grinding aid strengthening agent, it adopts following method to make:

[0023] First, add 500kg of polycarboxylic acid copolymer, 90kg of triisopropanolamine, 100kg of triethanolamine, 40kg of propylene glycol, and 70kg of ethylene glycol into the reaction vessel, heat to 50-60°C and stir for 0.5-1.5 hours to make uniform mixing to make 1 No. mixture; then add 50kg esterifying agent, 250kg carbonamide, 180kg calcium formate, and 20kg coagulation regulator into 700kg water, and stir fully at 50-60°C for 0.5-1.0 hours to make No. 2 mixture; then mix 1 No. mixture is maintained at 50-60°C, slowly poured into No. 2 mixture while stirring, and fully stirred for 0.5-1.5 hours to obtain a brown liquid that is not easy to precipitate and the composite cement grinding aid enhancer of the present invention.

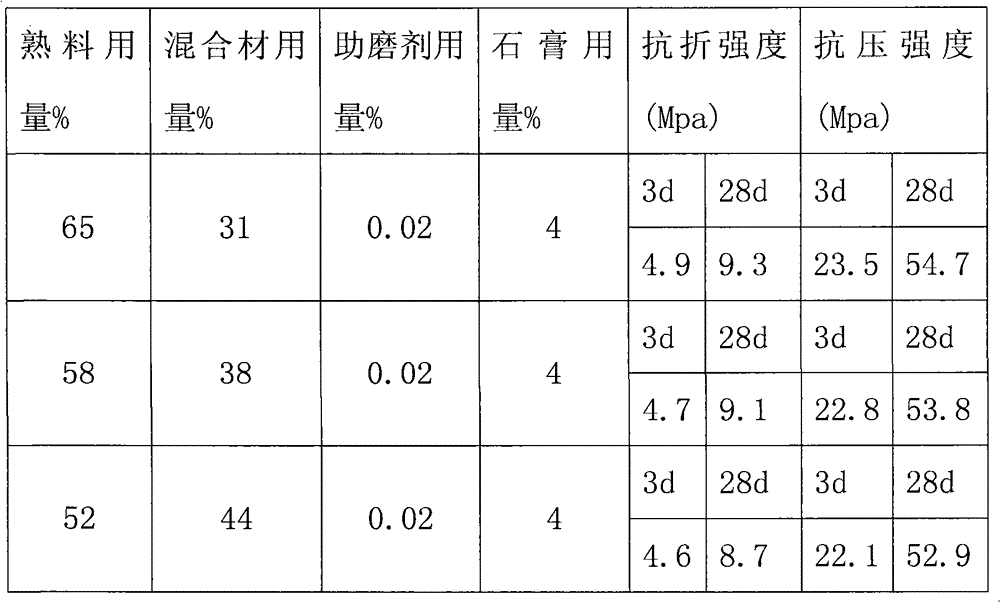

[0024] The composite cement grinding aid enhancer of the present invention has an obvious grinding aid effect on cement when the added amount is 2...

Embodiment 2

[0027] A kind of composite cement grinding aid strengthening agent, it adopts following method to make:

[0028] First, add 300kg of polycarboxylic acid copolymer, 60kg of triisopropanolamine, 70kg of triethanolamine, 25kg of propylene glycol, and 45kg of ethylene glycol into the reaction vessel, heat to 50-60°C and stir for 0.5-1.5 hours to uniformly mix to make 1 No. mixture; then add 100kg esterifying agent, 180kg carbonamide, 200kg calcium formate, 20kg coagulation regulator into 1000kg water, and stir fully at 50-60°C for 0.5-1.0 hours to make No. 2 mixture; then mix 1 No. mixture is maintained at 50-60°C, slowly poured into No. 2 mixture while stirring, and fully stirred for 1 hour to obtain a brown liquid that is not easy to precipitate and the composite cement grinding aid enhancer of the present invention.

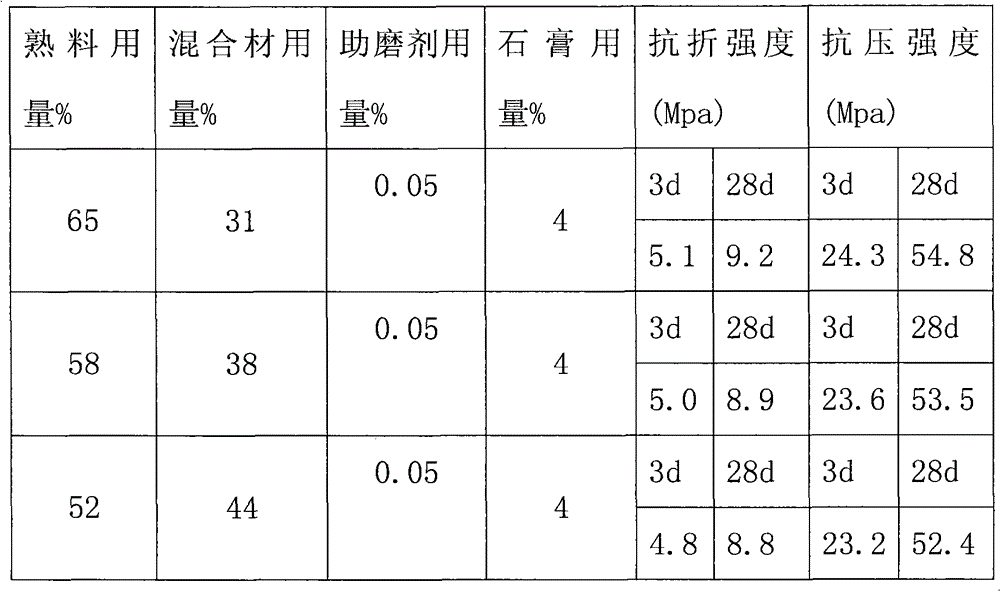

[0029] The composite cement grinding aid enhancer of the present invention has an obvious grinding aid effect on cement when the addition amount is 5 / 10,000, and ...

Embodiment 3

[0032] A kind of composite cement grinding aid reinforcing agent, it adopts following method to make:

[0033] First, 280kg of polycarboxylic acid copolymer, 50kg of triisopropanolamine, 55kg of triethanolamine, 15kg of propylene glycol, and 40kg of ethylene glycol are added to the reaction vessel, heated to 50-60°C and stirred for 0.5-1.5 hours to make uniform mixing to make 1 No. 2 mixture; then add 250kg esterifying agent, 150kg carbonamide, 150kg calcium formate, 10kg coagulation regulator into 1000kg water, and fully stir at 50-60°C for 0.5-1.0 hours to make No. 2 mixture; then 1 No. mixture is maintained at 50-60°C, slowly poured into No. 2 mixture while stirring, and fully stirred for 0.5-1.5 hours to obtain a brown liquid that is not easy to precipitate and the composite cement grinding aid enhancer of the present invention.

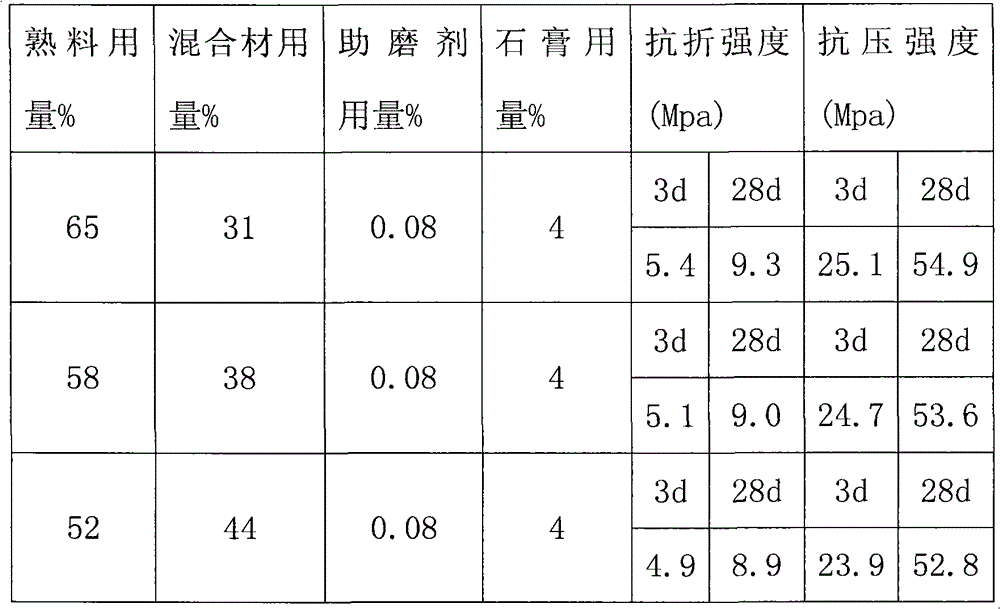

[0034] The composite cement grinding aid enhancer of the present invention has an obvious grinding aid effect on cement when the addition amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com