Slow-release retarder for shrinkage-compensating concrete, preparation method and application thereof

A technology for compensating shrinkage and concrete, applied in the field of concrete admixtures, can solve problems such as troublesome joint filling construction, leaving hidden dangers, etc., to achieve the effect of improving the compensation effect, improving the limiting expansion rate, and meeting the construction requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

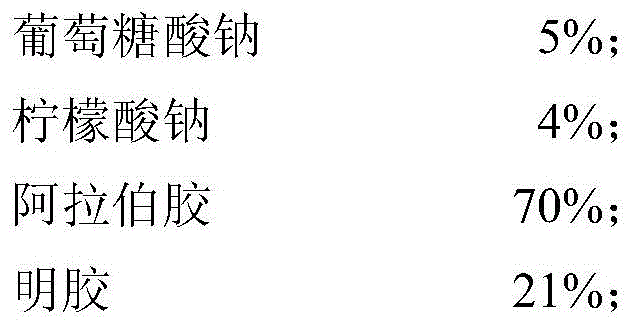

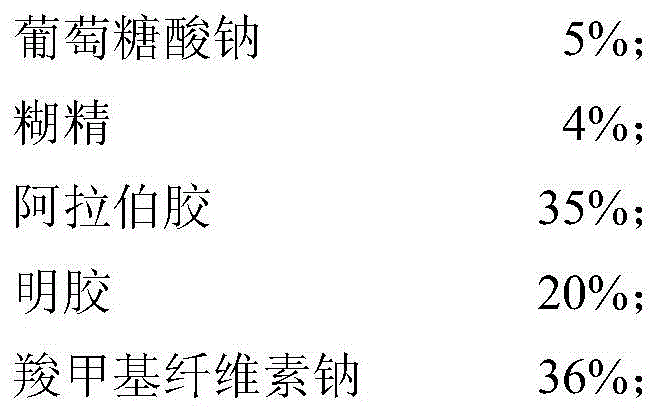

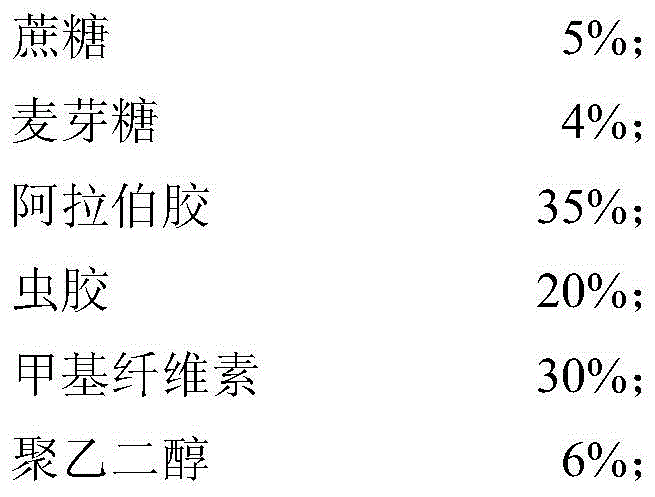

[0033] Calculate the following substances by mass:

[0034] Sodium Gluconate 5%;

[0035] Gum Arabic 95%;

[0036] Put it into a beaker, add water, dissolve at room temperature or properly (heating cannot make it boil), and keep stirring to accelerate the dissolution until there are no particles in the solution, then pour the solution into a suitable container, put the water in an oven at 90°C Completely evaporate to dryness, and grind through 80μm square hole sieve to prepare slow-release retarder.

Embodiment 2

[0038] Calculate the following substances by mass:

[0039] Sodium Gluconate 15%;

[0040] Gum Arabic 85%;

[0041] Put it into a beaker, add water, dissolve at room temperature or properly (heating cannot make it boil), and keep stirring to accelerate the dissolution until there are no particles in the solution, then pour the solution into a suitable container, put the water in an oven at 90°C Completely evaporate to dryness, and grind through 80μm square hole sieve to prepare slow-release retarder.

Embodiment 3

[0043] Calculate the following substances by mass:

[0044] Sodium Gluconate 9%;

[0045] Gum Arabic 91%;

[0046] Put it into a beaker, add water, dissolve at room temperature or properly (heating cannot make it boil), and keep stirring to accelerate the dissolution until there are no particles in the solution, then pour the solution into a suitable container, put the water in an oven at 90°C Completely evaporate to dryness, and grind through 80μm square hole sieve to prepare slow-release retarder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com