A kind of shrinkage-reducing polycarboxylate water-reducing agent and preparation method thereof

A technology of polycarboxylate and water reducer, applied in the field of concrete admixture, can solve the problems of affecting the stability of polycarboxylate water reducer, limiting polycarboxylate water reducer, affecting the setting time of concrete, etc., to improve the adsorption conformation , The preparation method is simple, and the effect of strengthening the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The present embodiment provides a shrinkage-reducing polycarboxylate water-reducing agent and a preparation method thereof, specifically:

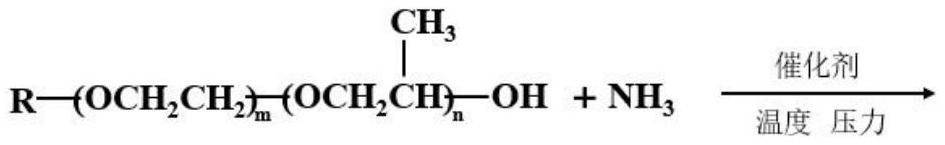

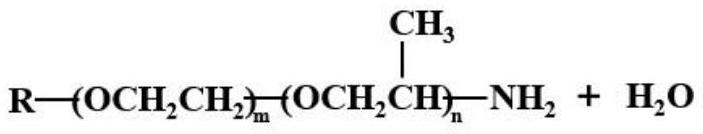

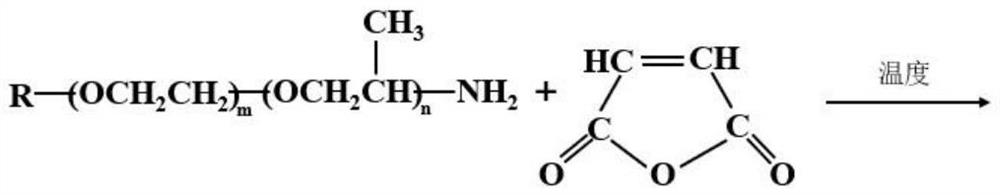

[0033] S1, the mass ratio of nickel and magnesium oxide of 2:1 is filled in an airtight container as a catalyst, and into the airtight container, R group is added hydroxy-terminated polyoxyethylene polyoxypropylene ether of phenethylphenol (where m=10 , n=4) and liquid nitrogen, and the mass ratio of the hydroxyl-terminated polyoxyethylene polyoxypropylene ether and liquid nitrogen is 1:0.04, the reaction temperature is controlled at 200-250°C, and the reaction pressure is controlled at 1-20Mpa, The ammoniation reaction was carried out for 2 hours; after the reaction product was separated from gas and liquid, the liquid material was dehydrated and deaminated, and then placed in a closed container for ammoniation, so that the hydroxyl-terminated polyoxyethylene polyoxypropylene ether was completely aminated, and finally the reaction p...

Embodiment 2

[0038]The difference between this example and Example 1 is that: methallyl polyoxyethylene ether, maleic acid acylated polyetheramine, ethylenically unsaturated carboxylic acid of acrylic acid, oxidant of hydrogen peroxide, corbic acid The mass ratio of the reducing agent and the molecular weight regulator of thioglycolic acid was 100:3:10:0.5:0.3:0.5.

Embodiment 3

[0040] Wherein the mass ratio of methallyl polyoxyethylene ether, maleic acid acylated polyetheramine, ethylenically unsaturated carboxylic acid of acrylic acid, oxidant of hydrogen peroxide, corbic acid reducing agent and molecular weight regulator of mercaptoacetic acid is: 100:3:12:0.5:0.3:0.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com