Water-soluble polymer grinding aid prepared from papermaking waste liquor and preparation method thereof

A technology of water-soluble polymer and papermaking waste liquid, which is applied in the new field of cement industry to achieve the effect of improving utilization rate, strength, flexural strength and compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

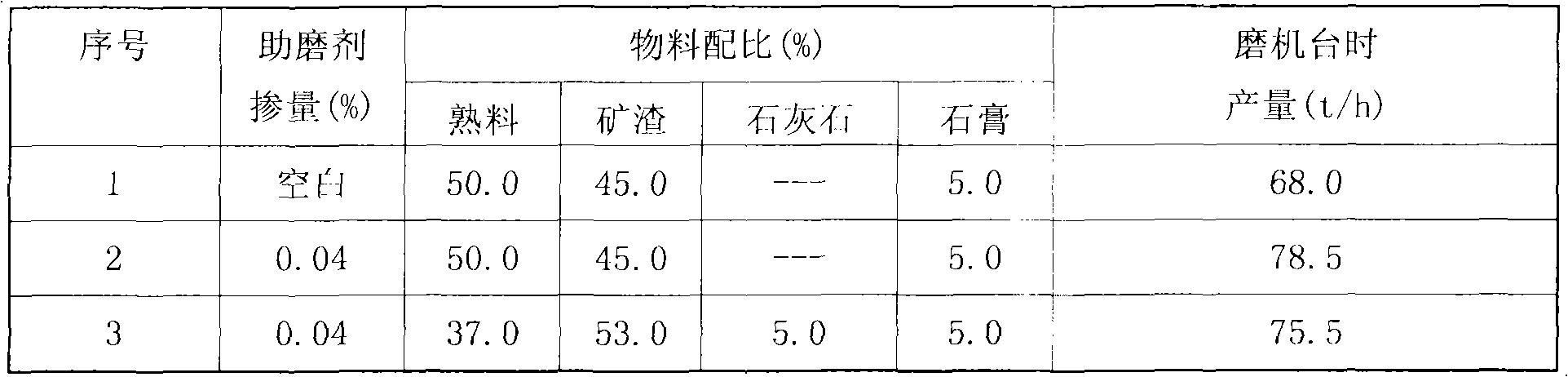

Examples

Embodiment 1

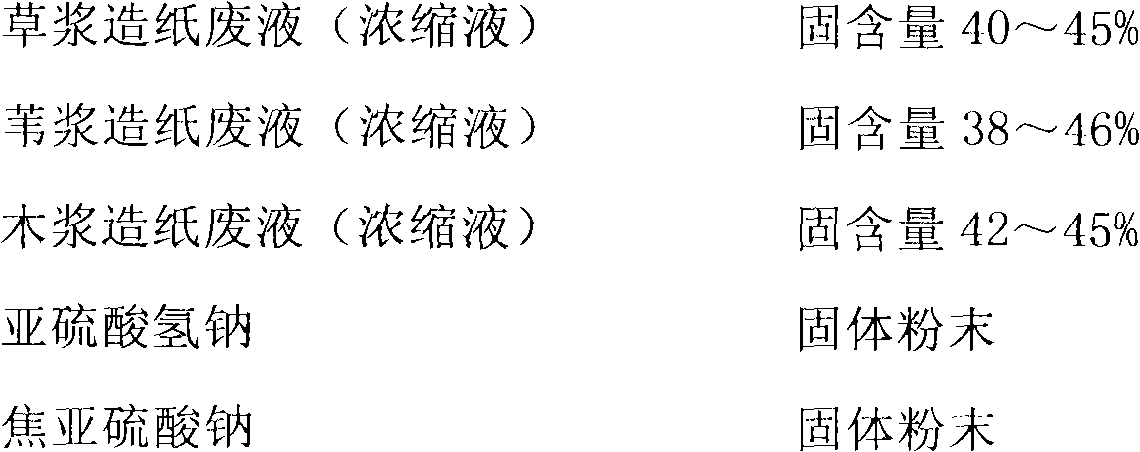

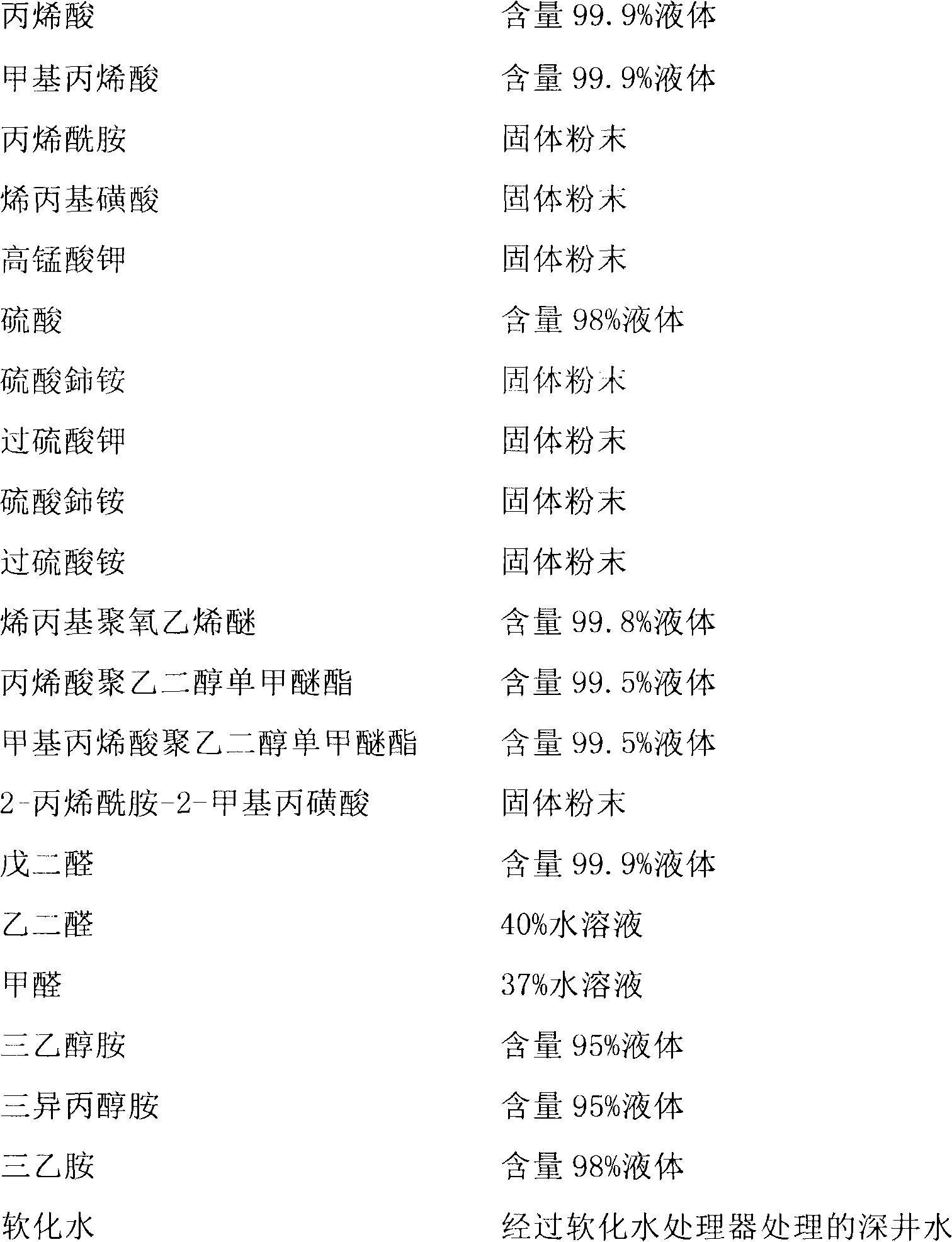

[0070] The mass ratio fraction of the present embodiment is as follows:

[0071] Basic reaction material: 26% (calculated on a dry basis of 100% solid content), the basic reaction material is straw pulp papermaking waste liquid (concentrated liquid, the used pulp raw material of straw pulp papermaking waste liquid is wheat straw), and the solid content is 42%;

[0072] Sulfonating agent: 4%, the sulfonating agent is sodium bisulfite;

[0073] Graft modifier: 6%, the graft modifier is methacrylic acid;

[0074] Grafting initiator: 0.2%, the grafting initiator is potassium permanganate-sulfuric acid system, the mass ratio of potassium permanganate and sulfuric acid is 1:2; water-soluble polymerization reaction material: 12%, water-soluble polymerization reaction material It is a mixture of allyl polyoxyethylene ether, polyethylene glycol monomethyl ether acrylate, and allyl sulfonic acid, and their mass ratio is allyl polyoxyethylene ether: polyethylene glycol monomethyl ether ...

Embodiment 2

[0088] The proportioning number of present embodiment is as follows:

[0089] Basic reaction material: 22% (calculated on a dry basis of 100% solid content), the basic reaction material is a mixture of reed pulp papermaking waste liquid (concentrate) and wood pulp papermaking waste liquid (concentrate), with a solid content of 44%;

[0090] Sulfonating agent: 6%, the sulfonating agent is sodium metabisulfite;

[0091] Graft modifier: 5%, the graft modifier is acrylic acid;

[0092] Grafting initiator: 0.1%, the grafting initiator is ceric ammonium sulfate-potassium persulfate system, the mass ratio of ceric ammonium sulfate and ammonium persulfate is 1:3;

[0093] Water-soluble polymerization reaction material: 18%, water-soluble polymerization reaction material is methacrylic acid, allyl polyoxyethylene ether, polyethylene glycol monomethyl ether acrylic acid ester, 2-acrylamide-2-methylpropanesulfonic acid A mixture whose mass ratio is methacrylic acid: allyl polyoxyethyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of repose | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com