Fully-automatic plasma treatment equipment and fully-automatic plasma treatment method

A fully automatic technology for plasma processing, applied in the field of plasma processing equipment, can solve problems such as poor reproducibility, affecting protein solubility, and high manual production costs, and achieve the goals of improving recovery and yield, reducing production costs, and reducing sales costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

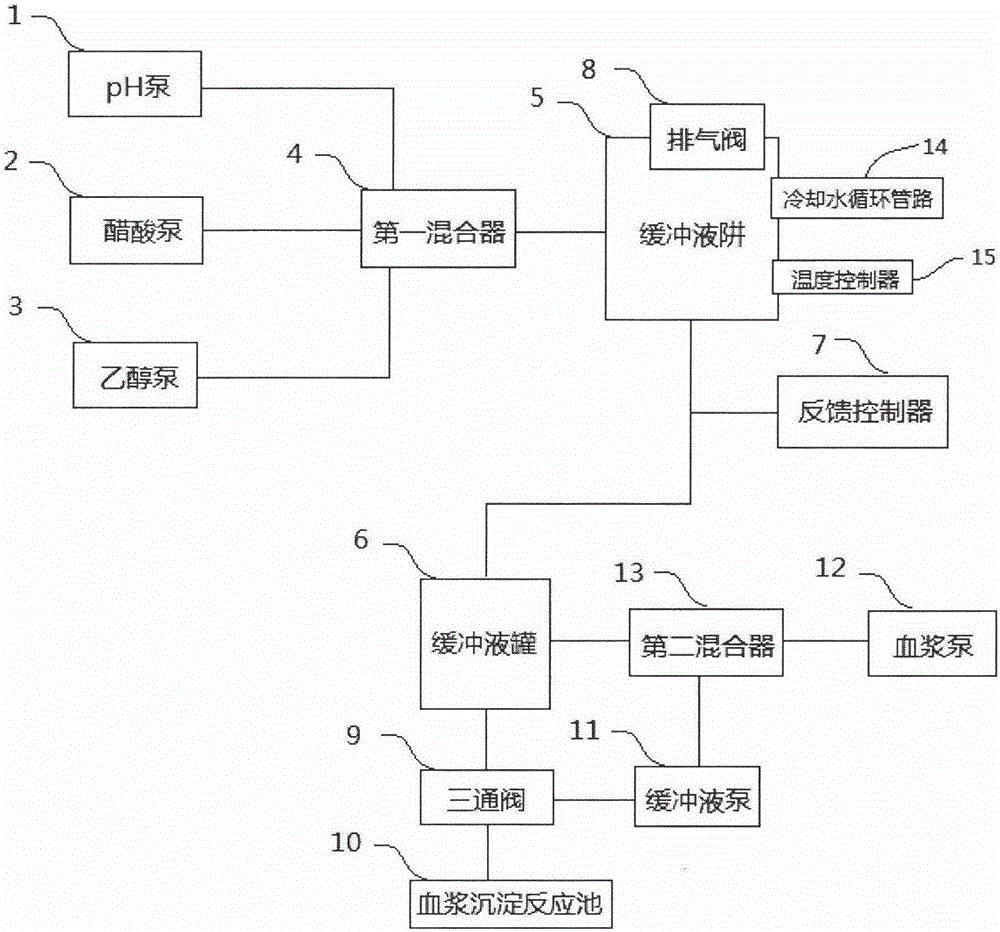

[0022] A kind of automatic plasma processing equipment of this embodiment, such as figure 1 As shown, it includes pH pump 1 for transporting pH adjustment solution, acetic acid pump 2 for transporting acetic acid, and ethanol pump 3 for transporting ethanol, after pH pump 1, acetic acid pump 2 and ethanol pump 3 are connected in parallel It communicates with the inlet port of the first mixer 4, and the outlet port of the first mixer 4 is connected in series with the buffer well 5 and the buffer tank 6 successively, and a feedback controller 7 is arranged between the buffer well 5 and the buffer tank 6, The feedback controller 7 includes an ethanol concentration detector, a conductivity detector and a pH value detector. The buffer trap 5 is provided with a cooling water circulation pipeline 14 and a temperature controller 15 for heat exchange. The feedback controller 7 is respectively connected to the pH pump 1, the acetic acid pump 2 and the ethanol pump 3; the buffer trap 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com