Fully automatic plasma processing equipment and processing method

A plasma processing, fully automatic technology, applied in peptide preparation methods, chemical instruments and methods, peptides, etc., can solve the problems of poor reproducibility, human error in feeding, lack of storage space, etc., to improve recovery and yield , reduce production costs, reduce the effect of problem products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

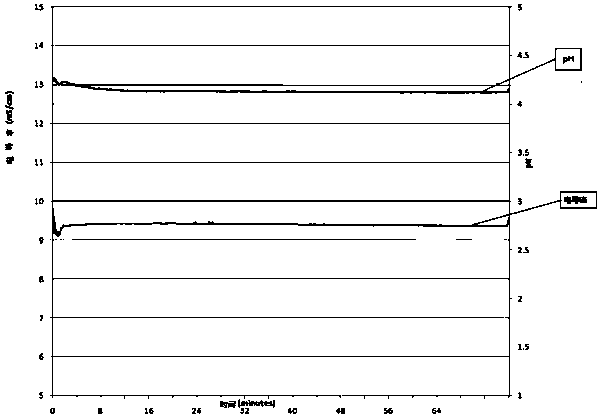

Examples

Embodiment Construction

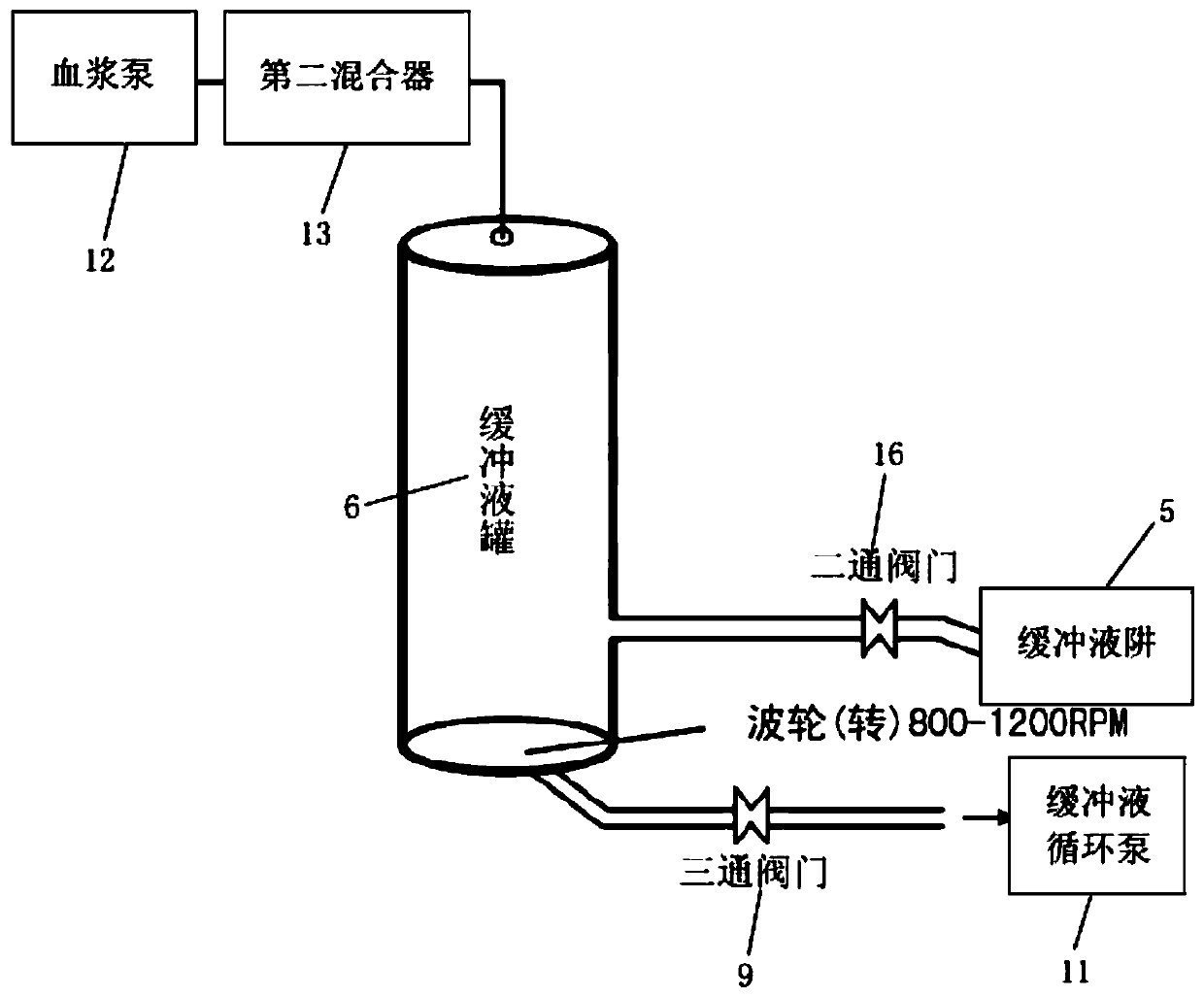

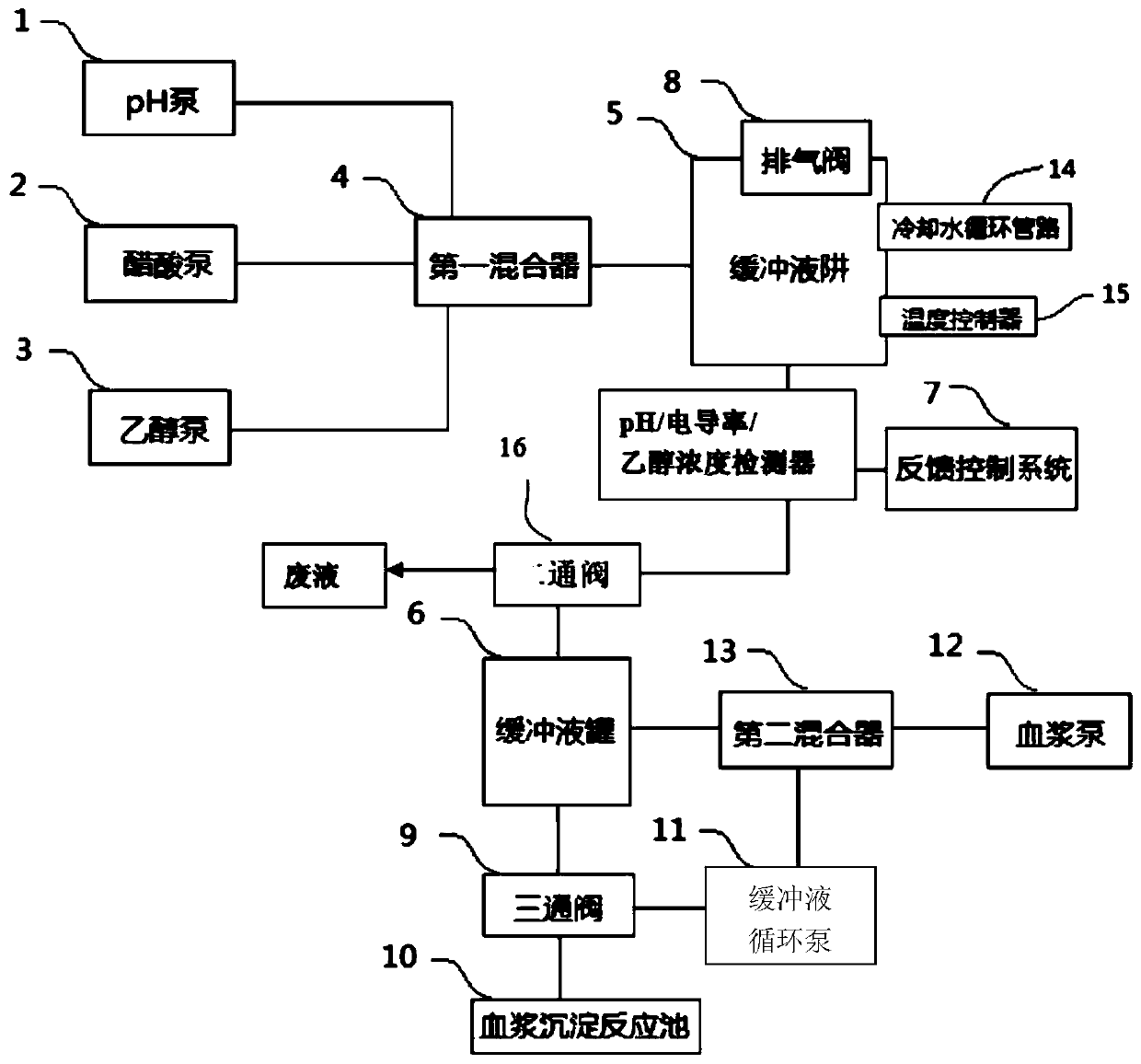

[0032] In view of the deficiencies in the prior art, the inventor of this case was able to propose the technical solution of the present invention after long-term research and extensive practice. The technical solution, its implementation process and principle will be further explained in conjunction with the accompanying drawings and embodiments as follows. However, it should be understood that within the scope of the present invention, the above-mentioned technical features of the present invention and the technical features specifically described in the following (such as embodiments) can be combined with each other to form new or preferred technical solutions. Due to space limitations, we will not repeat them here.

[0033] In a typical embodiment of the present invention, a fully automatic plasma processing equipment is provided, which includes:

[0034] pH pump for transporting pH adjustment solution;

[0035] Acetic acid pump for conveying acetic acid;

[0036] Ethan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com