Halogen-free flame-retardant TPE cable material with heat resistance and oil resistance and preparation method of cable material

A cable material and oil-resistant technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems that restrict the application of electric vehicle charging cables, poor process reproducibility, low tensile strength, etc., and achieve good elasticity, good physical properties, Good electrical insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

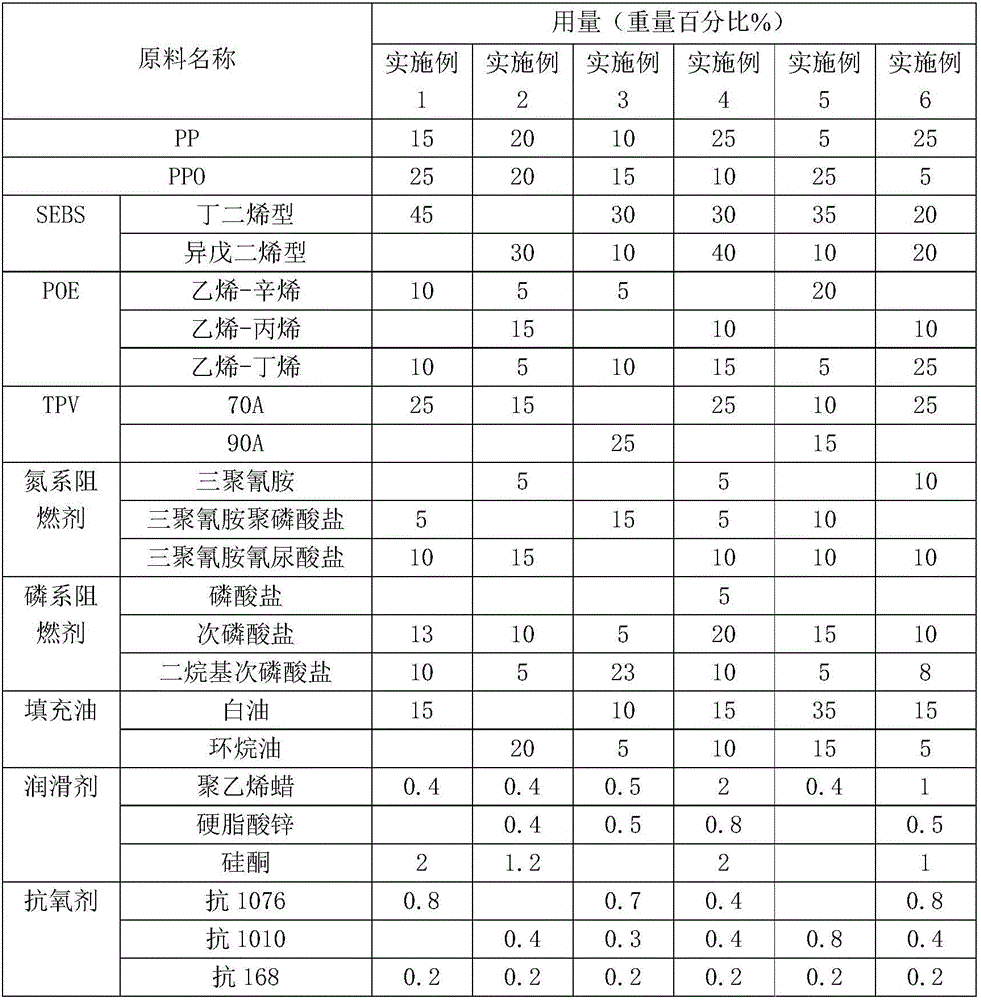

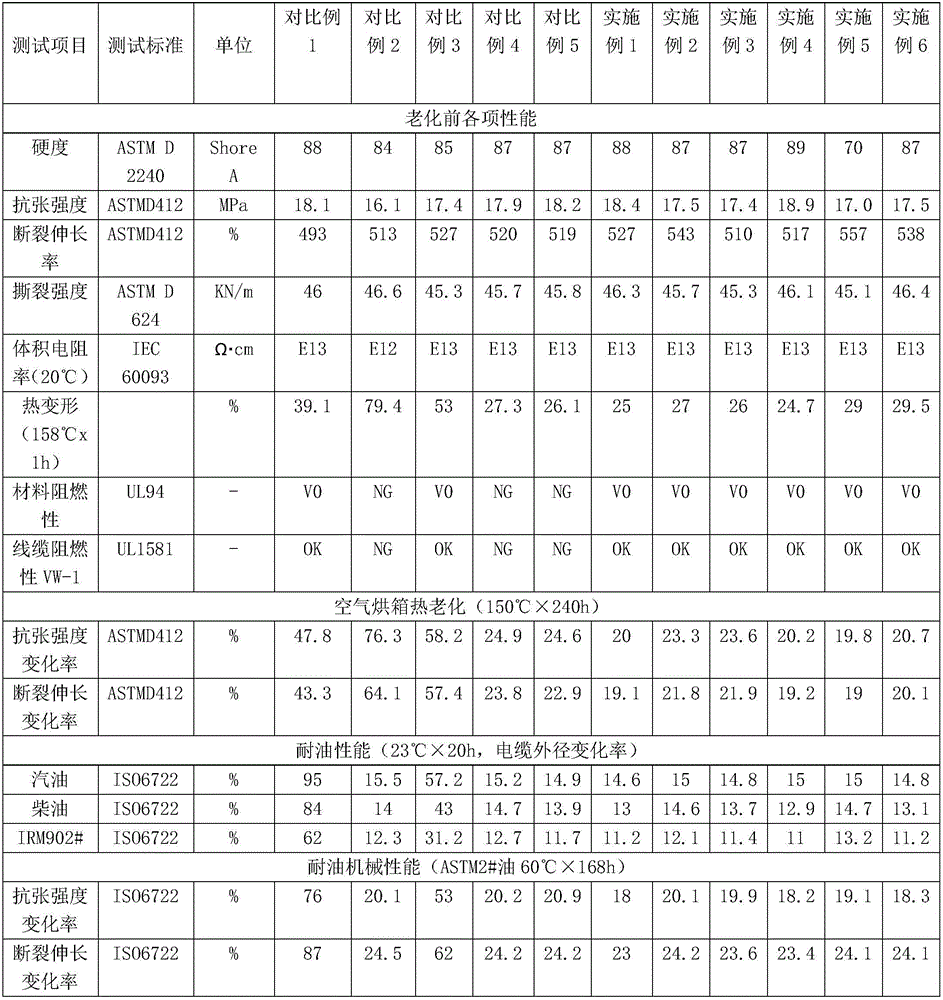

Embodiment 1

[0035] Put SEBS and filler oil weight percent described in the embodiment 1-6 in the above table into after weighing in the low-speed mixer and stir for 3min, stand for 12h after stand-by, make SEBS fully absorb oil and swell; After weighing the proportion, mix it in a high mixer for 5 minutes to obtain the compound; put the mixed material into the twin-screw extruder for melting and kneading and extrude. Section 180-190°C, melting section 195-210°C, shearing section 190-200°C, die section 180-185°C, head 170-180°C, water-cooled strand cutting, boiling drying to obtain a temperature resistance of 125°C Oil-resistant, halogen-free, flame-retardant TPE cable compound.

Embodiment 2-6

[0037] The materials were weighed according to the components and weight percentages described in Examples 2-6 in the above table, and the halogen-free flame-retardant TPE cable material of the present invention was prepared by the process as described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com