A kind of marble saw mud waste putty paste

A technology of marble and putty paste, which is applied in the field of marble sawing mud waste putty paste, can solve problems such as human health hazards, indoor air pollution, and harm to the health of construction workers, so as to strengthen market competitiveness, increase enterprise benefits, and have significant economic effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: a kind of marble sawing mud waste putty paste, comprises the component of following parts by weight: Marble sawing mud waste: 70 parts; Polyvinyl alcohol: 0.2 part; Hydroxymethyl cellulose: 0.15 part; Aiweibei starch Ether: 0.02 parts; Water: 23 parts.

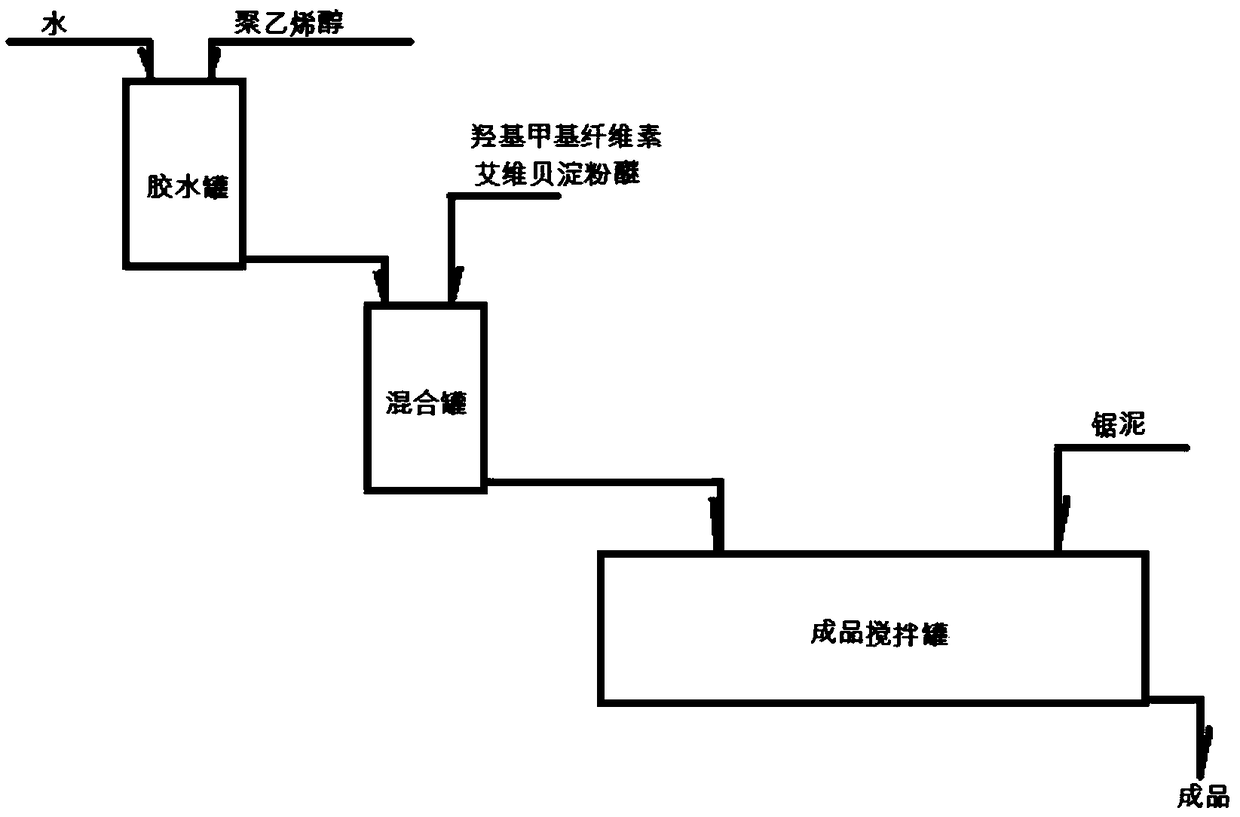

[0017] The production steps are: a. Mixing glue: add water to the glue tank, add polyvinyl alcohol after heating to 100°C, keep warm and stir for 30 minutes at 100°C; b. Mix additives: mix the glue prepared in the glue tank Put it into the mixing tank, then add the additives hydroxymethylcellulose BNE-119C and Aiweibei starch ether, and stir for 20 minutes; c. Preparation: put the mixed and prepared additive solution into the finished product mixing tank, and then add marble sawing mud waste , and then stir and mix for 30 minutes; d. Packaging: After stirring and mixing evenly, it can be weighed and packaged.

Embodiment 2

[0018] Embodiment 2: a kind of marble sawing mud waste putty paste, comprises the component of following parts by weight: Marble sawing mud waste: 80 parts; Polyvinyl alcohol: 0.6 part; Hydroxymethyl cellulose: 0.3 part; Aiweibei starch Ether: 0.07 parts; Water: 26 parts.

[0019] The production steps are: a. Mixing glue: add water to the glue tank, add polyvinyl alcohol after heating to 100°C, keep warm and stir for 30 minutes at 100°C; b. Mix additives: mix the glue prepared in the glue tank Put it into the mixing tank, then add the additives hydroxymethylcellulose BNE-119C and Aiweibei starch ether, and stir for 20 minutes; c. Preparation: put the mixed and prepared additive solution into the finished product mixing tank, and then add marble sawing mud waste , and then stir and mix for 30 minutes; d. Packaging: After stirring and mixing evenly, it can be weighed and packaged.

Embodiment 3

[0020] Embodiment 3: a kind of marble sawing sludge waste putty paste, comprising the following components in parts by weight: marble sawing sludge waste: 75 parts; polyvinyl alcohol 100-27S: 0.4 part; hydroxymethylcellulose BNE-119C: 0.25 parts; Aiweibei starch ether: 0.05 parts; water: 24.3 parts.

[0021] The production steps are: a. Mixing glue: add water to the glue tank, add polyvinyl alcohol after heating to 100°C, keep warm and stir for 30 minutes at 100°C; b. Mix additives: mix the glue prepared in the glue tank Put it into the mixing tank, then add the additives hydroxymethylcellulose BNE-119C and Aiweibei starch ether, and stir for 20 minutes; c. Preparation: put the mixed and prepared additive solution into the finished product mixing tank, and then add marble sawing mud waste , and then stir and mix for 30 minutes; d. Packaging: After stirring and mixing evenly, it can be weighed and packaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com