Environmentally-friendly soil repairing agent

A soil remediation agent and an environmentally friendly technology, applied in the field of soil remediation, can solve the problems of reduced crop biomass, poor remediation effect, and biological toxicity, and achieves a short remediation period, which is conducive to promotion and application, and has good effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

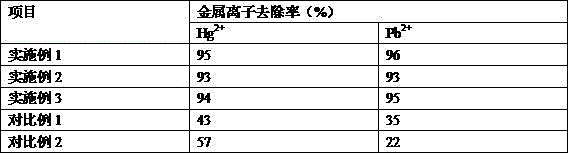

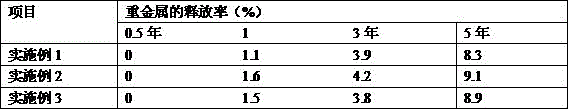

Examples

Embodiment 1

[0024] An environment-friendly soil restoration agent, the main components of the soil restoration agent include in parts by weight: 64 parts of shell powder, 21 parts of sodium dihydrogen phosphate, 16 parts of proline, 9 parts of histidine, 13 parts of organic acid 52 parts of enzymolysis product A, 11 parts of enzymolysis product B, 7 parts of vitamin C.

[0025] In particular, the organic acid is citric acid.

[0026] Further, the enzymatic hydrolysis product A is quinoa enzymatic hydrolysis product, and its preparation method is: S1. Crush the quinoa with a mixer, add water at a ratio of 1:5, soak at 65°C for 10 minutes, and filter to obtain a filter residue; S2. Add water according to the solid-to-liquid ratio of 1:2, mix evenly, pretreat in a microwave with a power of 350w for 1min, add cellulase, and the enzyme dosage is 600U·g -1 , pH value 4.0, enzymolysis temperature 50°C, reaction time 8h, after the reaction, inactivate the enzyme in a boiling water bath for 10min...

Embodiment 2

[0029] An environment-friendly soil restoration agent, the main components of the soil restoration agent include in parts by weight: 55 parts of shell powder, 21 parts of sodium dihydrogen phosphate, 16 parts of proline, 9 parts of histidine, 13 parts of organic acid 46 parts of enzymolysis product A, 13 parts of enzymolysis product B and 7 parts of vitamin C.

[0030] In particular, the organic acid is a 1:1 mixed acid of oxalic acid and citric acid.

[0031] Further, the enzymatic hydrolysis product A is quinoa enzymatic hydrolysis product, and its preparation method is: S1. Crush the quinoa with a mixer, add water at a ratio of 1:5, soak at 65°C for 10 minutes, and filter to obtain a filter residue; S2. Add water according to the solid-to-liquid ratio of 1:2, mix evenly, pretreat in a microwave with a power of 350w for 1min, add cellulase, and the enzyme dosage is 600U·g -1 , pH value 4.0, enzymolysis temperature 50°C, reaction time 8h, after the reaction, inactivate the e...

Embodiment 3

[0034] An environment-friendly soil remediation agent, the main components of the soil remediation agent include by weight: 79 parts of shell powder, 21 parts of sodium dihydrogen phosphate, 16 parts of proline, 9 parts of histidine, 13 parts of organic acid 59 parts of enzymolysis product A, 9 parts of enzymolysis product B, 7 parts of vitamin C.

[0035] In particular, the organic acid is oxalic acid.

[0036] Further, the enzymatic hydrolysis product A is quinoa enzymatic hydrolysis product, and its preparation method is: S1. Crush the quinoa with a mixer, add water at a ratio of 1:5, soak at 65°C for 10 minutes, and filter to obtain a filter residue; S2. Add water according to the solid-to-liquid ratio of 1:2, mix evenly, pretreat in a microwave with a power of 350w for 1min, add cellulase, and the enzyme dosage is 600U·g -1 , pH value 4.0, enzymolysis temperature 50°C, reaction time 8h, after the reaction, inactivate the enzyme in a boiling water bath for 10min to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com