A method for preparing high-strength and high-plasticity aluminum matrix composite material

An aluminum-based composite material and composite material technology, applied in the field of preparing high-strength and high-plastic aluminum-based composite materials, can solve the problems of incompatibility of strength and plasticity, low cost, etc., to achieve strength and plasticity improvement, and refine grain structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Experiments were carried out with high-purity Al, industrial pure Mg, industrial pure Zn, Al-50Cu, Al-12Zr master alloy, KBF 4 and K 2 TiF 6 In situ self-generated 5wt.%TiB was formulated for the raw material 2 Reinforced Al-6.7Zn-2.2Mg-2.3Cu-0.1Zr alloy composites. Put high-purity Al into the crucible to melt and heat up to 780°C, and cover it with JZF-03 high-temperature covering agent; put KBF 4 、K 2 TiF 6 After mixing evenly according to the mass ratio of 1:2, add it to the melt obtained in step (1) after drying; after the reaction is completed, take out the reaction by-products, and add Al-50Cu, Al-12Zr master alloy and industrial pure Mg in sequence and industrial pure Zn, adding JZJ type harmless aluminum alloy refining agent to the melt for degassing refining, standing at 750°C for 15min, and then pouring into a mold at 730°C to form a slab. 5wt.%TiB obtained by casting 2 Reinforced Al-6.7Zn-2.2Mg-2.3Cu-0.1Zr alloy composites were homogenized for alloy el...

Embodiment 2

[0035] Experiments were carried out with high-purity Al, industrial pure Mg, industrial pure Zn, Al-50Cu, Al-12Zr master alloy, KBF 4 and K 2 TiF 6 In situ self-generated 5wt.%TiB was formulated for the raw material 2 Reinforced Al-6.6Zn-2.2Mg-2.2Cu-0.09Zr alloy composites. Put high-purity Al into the crucible to melt and heat up to 780°C, and cover it with JZF-03 high-temperature covering agent; put KBF 4 、K 2 TiF 6 After mixing evenly according to the mass ratio of 1:2, add it to the melt obtained in step (1) after drying; after the reaction is completed, take out the reaction by-products, and add Al-50Cu, Al-12Zr master alloy and industrial pure Mg in sequence and industrial pure Zn, adding JZJ type harmless aluminum alloy refining agent to the melt for degassing refining, standing at 750°C for 15min, and then pouring into a mold at 730°C to form a slab. 5wt.%TiB obtained by casting 2 Reinforced Al-6.7Zn-2.2Mg-2.3Cu-0.1Zr alloy composites were homogenized for alloy e...

Embodiment 3

[0037] A method for preparing high-strength and high-plasticity aluminum matrix composites, through the method of in-situ self-generated melt control, to prepare as-cast TiB 2 Particle-reinforced Al-8Zn-2.5Mg-2Cu-0.2Zr alloy composite material, and then use the self-designed orthogonal lamination extrusion equipment to realize the in-situ self-generated TiB 2 Multi-pass orthogonal lamination extrusion of particle-reinforced Al-8Zn-2.5Mg-2Cu-0.2Zr alloy composites with large plastic deformation to obtain uniformly dispersed micro-nano TiB 2 Particles and fine equiaxed matrix grain structure, combined with T6 heat treatment of Al-8Zn-2.5Mg-2Cu-0.2Zr alloy, prepared TiB with high strength and high plasticity 2 Particle reinforced Al-8Zn-2.5Mg-2Cu-0.2Zr alloy composites.

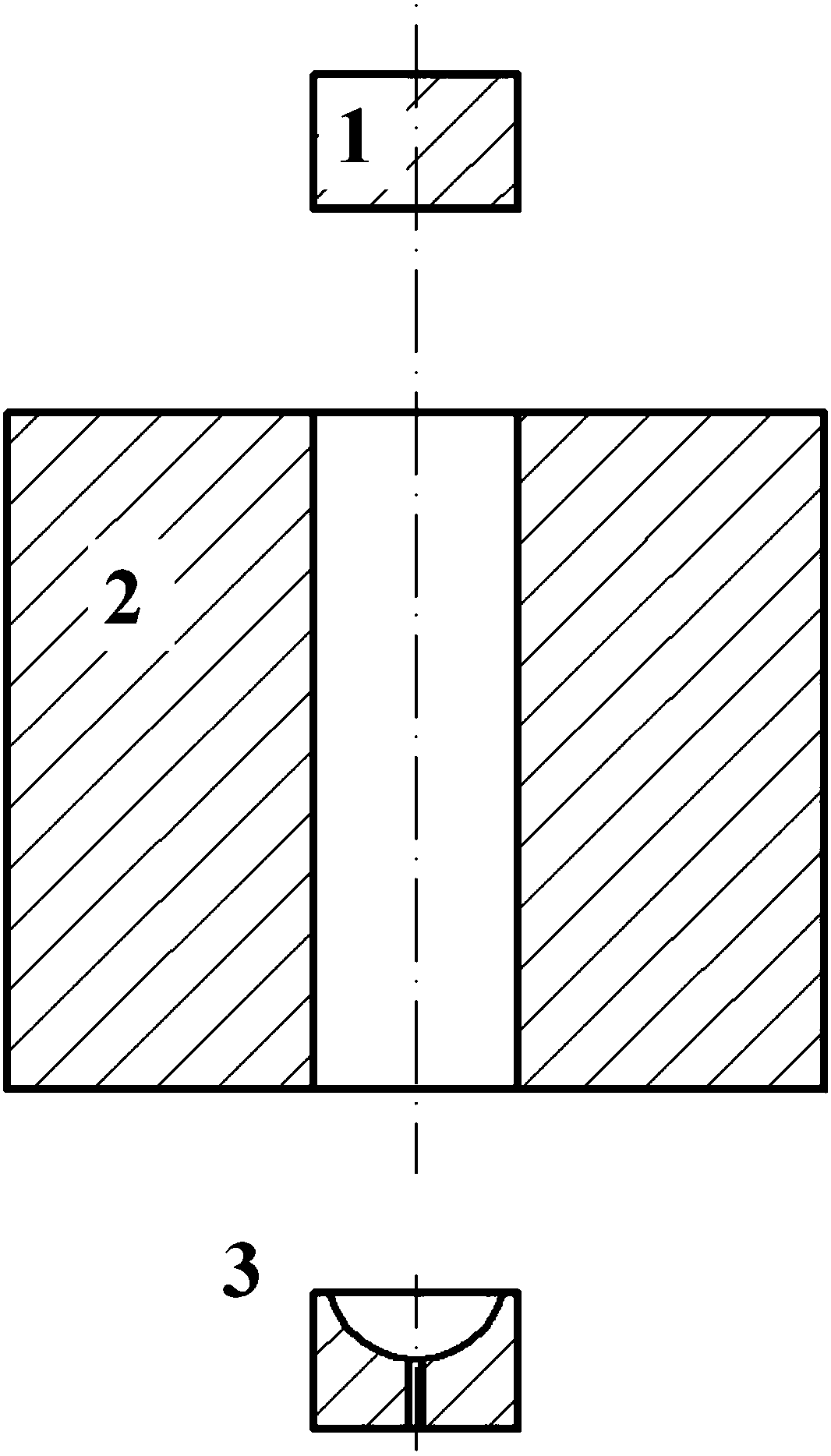

[0038] The structure of the cross lamination extrusion equipment used is as follows figure 1 As shown, it includes an upper pressing head 1, a mold cylinder 2 and a mold head 3. The middle part of the mold cyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com