Pulse type fracturing sliding sleeve

A pulsed and fracturing technology, applied in wellbore/well components, production fluids, sealing/packaging, etc., can solve the problems of difficulty in stabilizing production, large casing damage, rapid production decline, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

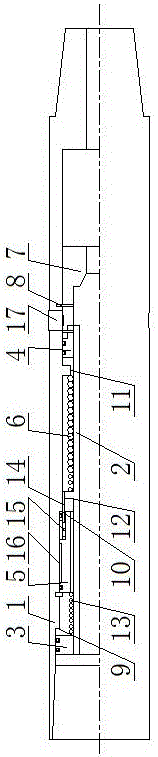

[0015] The pulse type fracturing sliding sleeve is composed of a casing 1, a magnetic block 3, a magnetic control device 5, a circulation sleeve 2, a circulation slide valve 4, and a fracturing slide valve 7. The casing 1 is provided with a circulation sleeve 2, and the circulation sleeve One end of 2 is threaded with a magnetic block 3, the other end of the circulation sleeve 2 is threaded with a circulation slide valve 4, and the middle part of the circulation sleeve 2 is provided with a protrusion 12, which is connected with the metal contact rod 14 of the magnetic control device 5 Threaded connection; the magnetic control device 5 is composed of a solenoid valve housing, a coil 16, a metal contact rod 14 and a metal contact piece 15. The magnetic control device 5 is installed between the boss A9 and the boss B10, and the coil 16 is wound around the solenoid valve. In the trunking of the casing, the metal contact rod 14 is in contact with the metal contact piece 15 .

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com