Combustion soaking heavy crude producing technique

A technology of combustion throughput and process technology, which is applied in the field of thermal recovery of heavy oil, can solve problems such as defects and difficulties in the exploitation of combustion oil layers, and achieve the effects of improving production dynamics and reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

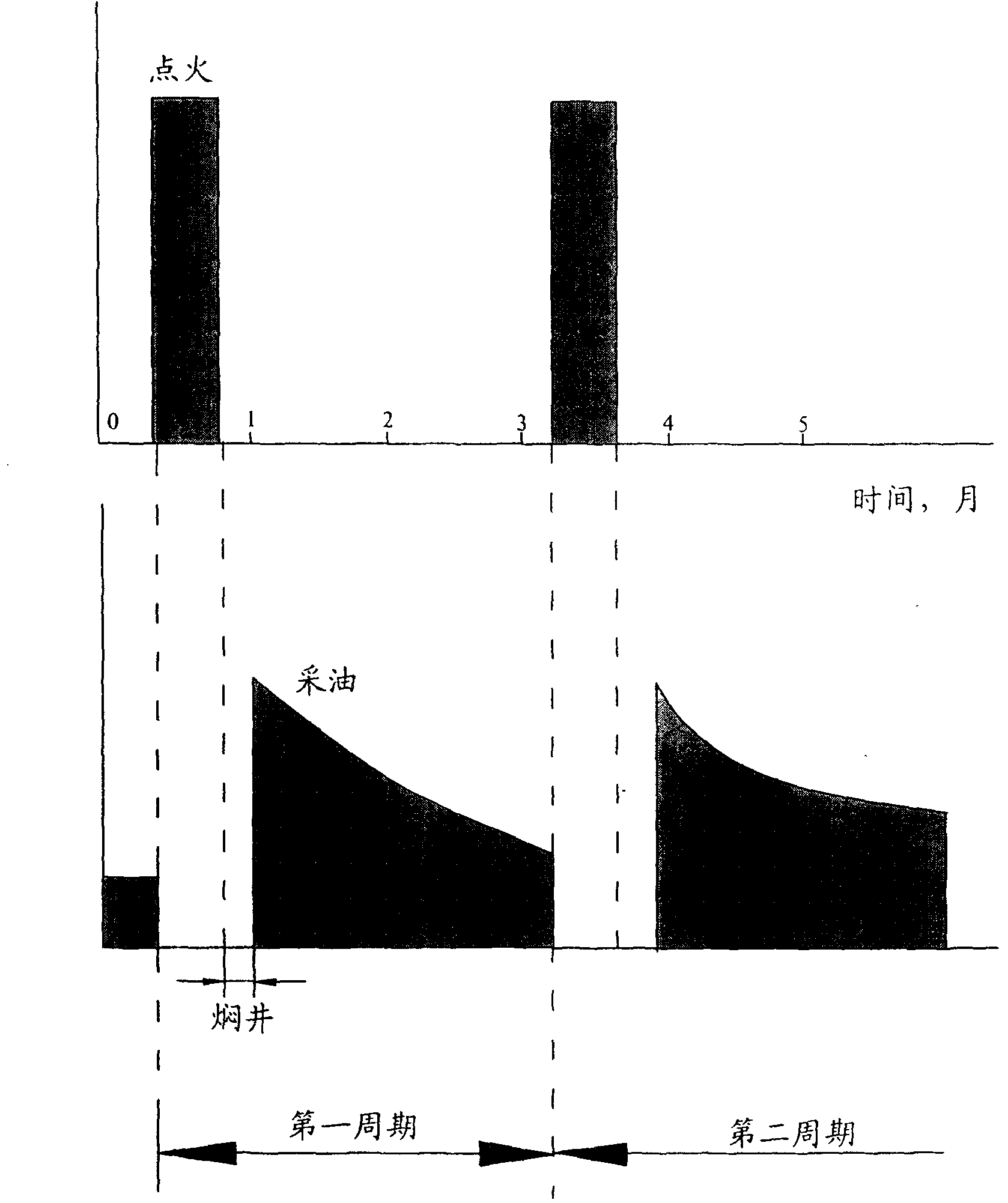

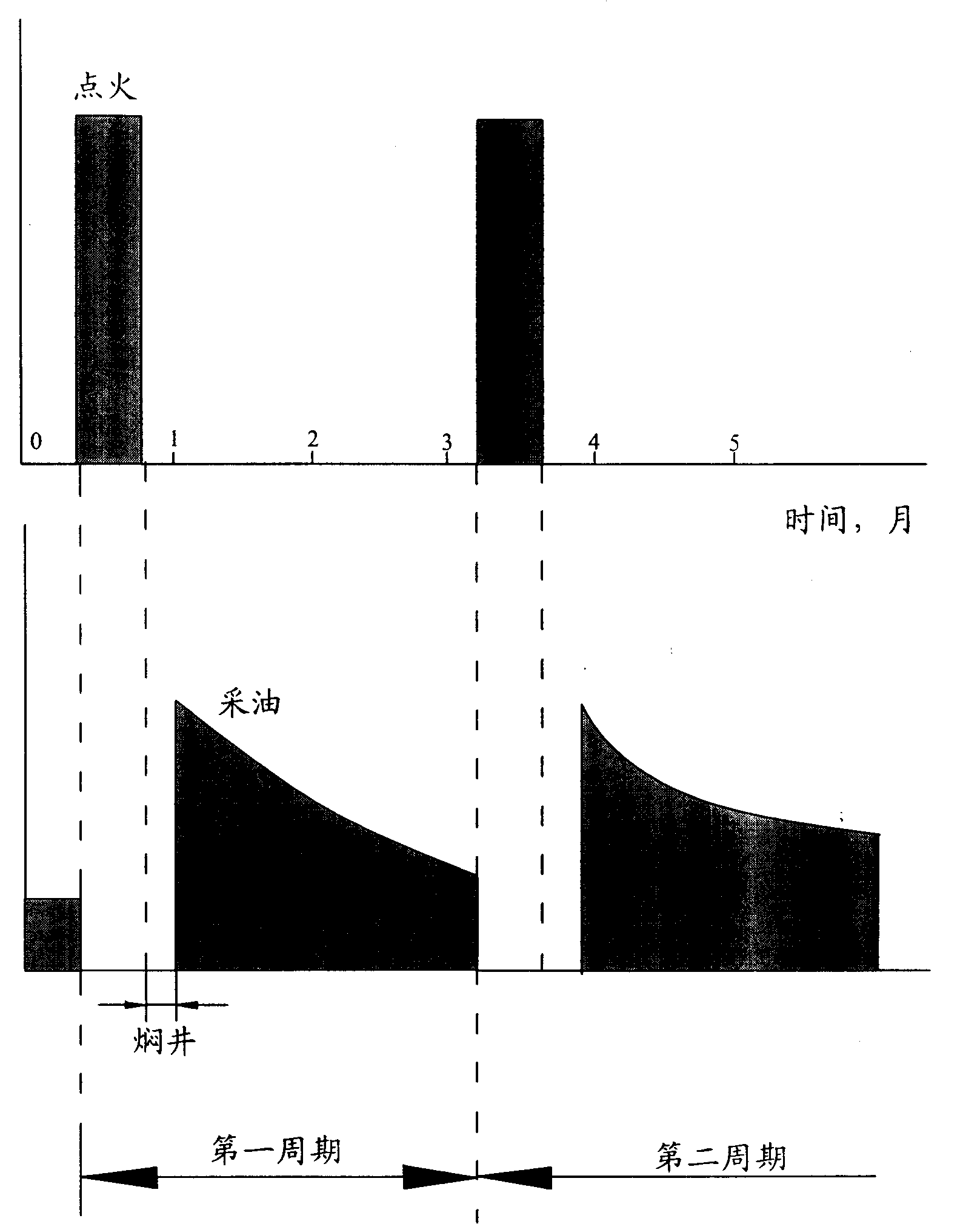

Image

Examples

Embodiment 1

[0036] The buried depth of the oil reservoir in Oilfield 1 is 300-600m, the effective thickness of the oil layer is 36.0m, the net total thickness ratio is 0.7, the average porosity is 28%, the permeability is 700-900md, the underground crude oil viscosity is 800mPa.s, and the oil production capacity before treatment Low, with a water content of 34%.

[0037] 1) Carry out rough screening according to the geological characteristics and development status of the oilfield. The reservoir meets the following conditions:

[0038] Reservoir depth0.5, total thickness of reservoir>6m, reservoir porosity>0.3, permeability>35md, crude oil viscosity<5000mPa.s;

[0039] 2) Use electric heater or natural gas to ignite, the temperature reaches 450°C, after igniting the oil layer, the temperature at the bottom of the well reaches 500°C, and stop the ignition after heating for 20-25°C;

[0040] 3) Inject air into the oil well with an air compressor, and the steam injection intensity reaches ...

Embodiment 2

[0043] Oilfield 2 reservoir is buried at 300-600m in depth, and is developed with an area well pattern similar to the five-point method with a well spacing of 100-150m. There are 14 water injection wells and 17 production wells in total. The volume of the convex lens sand layer in the oilfield is only 128000m 3 The net thickness of the sand layer in the middle of the oilfield is about 6.1m, and there are many shale in the whole sand layer in the form of strips. The porosity of the sand layer is 15-17%, the permeability is 1-80md, the average permeability is about 15md, and the specific gravity of crude oil is 0.859, underground crude oil viscosity 9mPa.s, low oil production capacity before treatment, water content up to 34%. 51,000 tons of crude oil have been produced in the entire oil field before the development of fire huffing and puffing.

[0044] 1) Carry out rough screening according to the geological characteristics and development status of the oilfield. The reservoir ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com