Double-layer gas exhaust pipeline and application thereof

An exhaust pipe, double-layer technology, applied in the direction of pipe heating/cooling, coating, pipes, etc., can solve the problems of high exhaust pipe temperature and affecting the operating environment of the equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

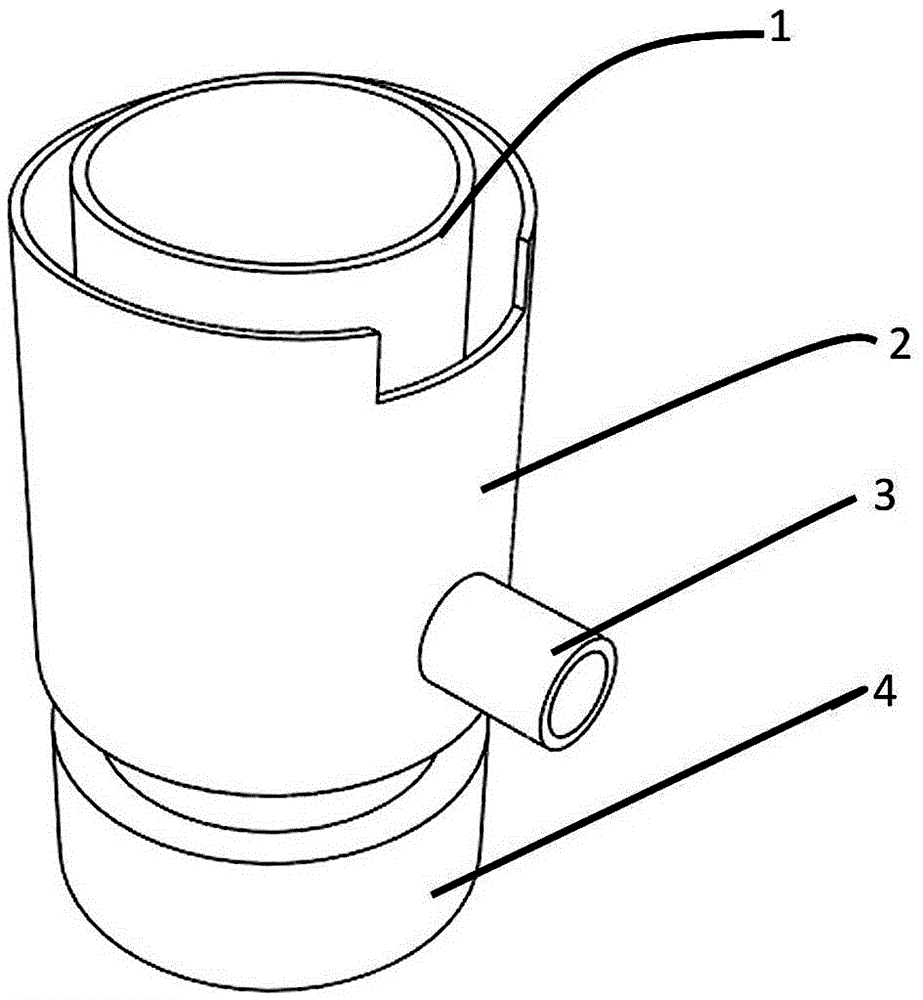

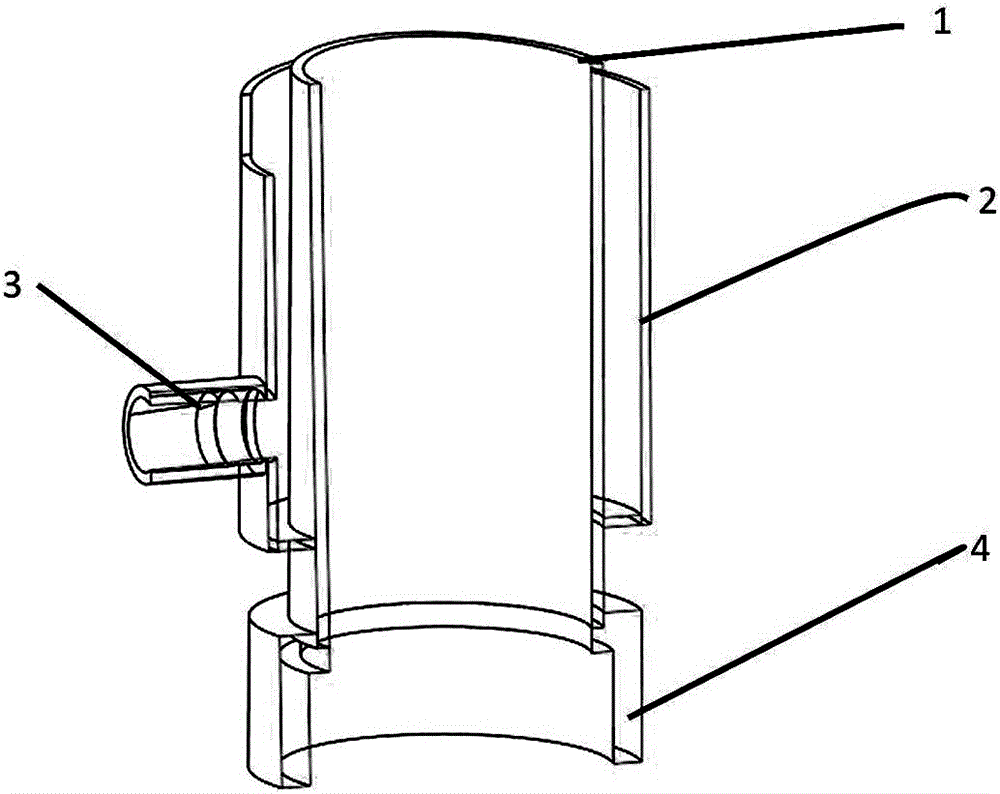

[0016] Such as figure 1 , and shown in 2 are structural schematic diagrams of a preferred embodiment of the present invention. The double-layer exhaust pipe includes an inner pipe 1, an outer pipe 2, and a cooling circulating water joint 3 communicated with the outer pipe , the thick tube 4 connected with the inner tube. Inner tube 1, the upper part is connected to the pipeline in the vacuum reaction chamber; the outer tube 2, the lower part is connected to the inner tube 1, and the upper part is connected to the outer wall of the vacuum chamber of ALD to form a hollow structure; cooling water connector 3, one end is connected to the outer tube The layer tube 2 forms a passage with the hollow structure between the inner and outer tubes, and the other end is used to connect the cooling circulating water; the inner diameter of the thick tube 4 is the same as the outer diameter of the inner tube, and the upper part is connected with the inner tube, and the lower part is used as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com