Water pump based on carbon graphite bearing and ceramic bearing

A technology of carbon-graphite bearings and ceramic bearings, which is applied to parts, pumps, and pumping devices of elastic fluid pumping devices, and can solve the problems of blockage of the round hole of the water filter cover, short service life, and inconvenient structure. Achieve the effects of reducing frictional resistance torque, avoiding environmental pollution, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

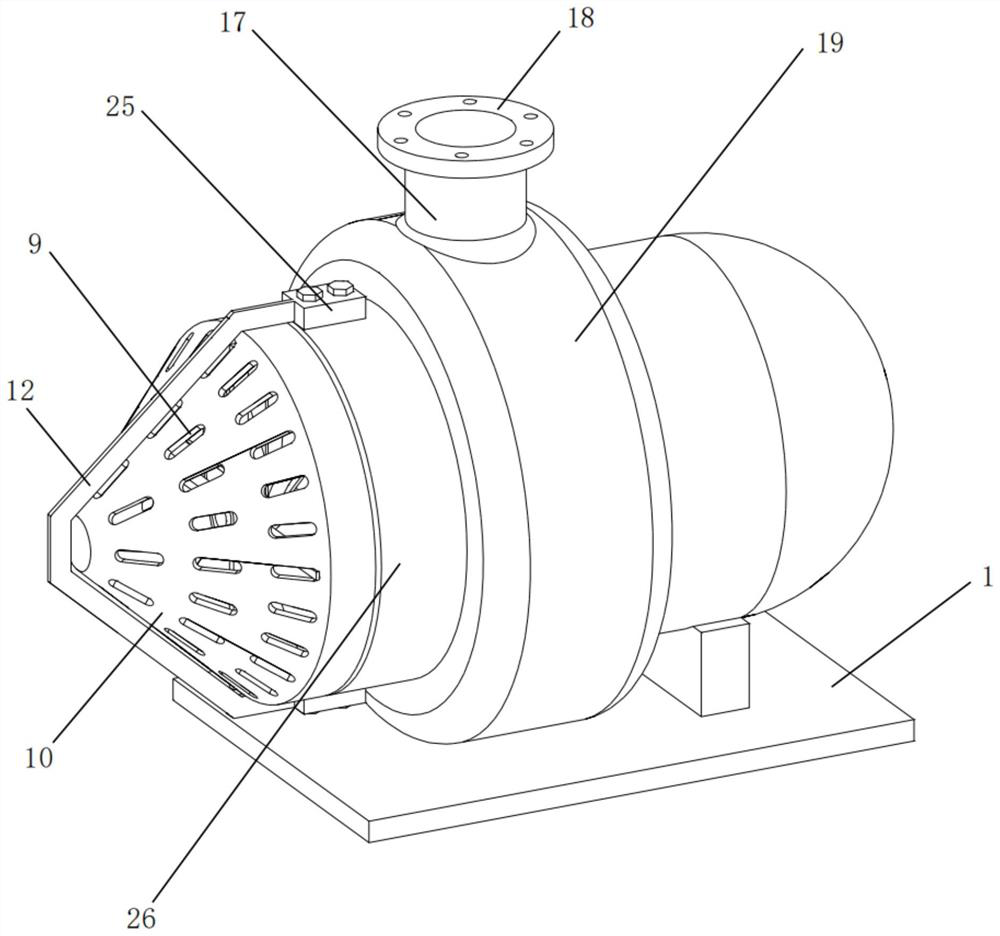

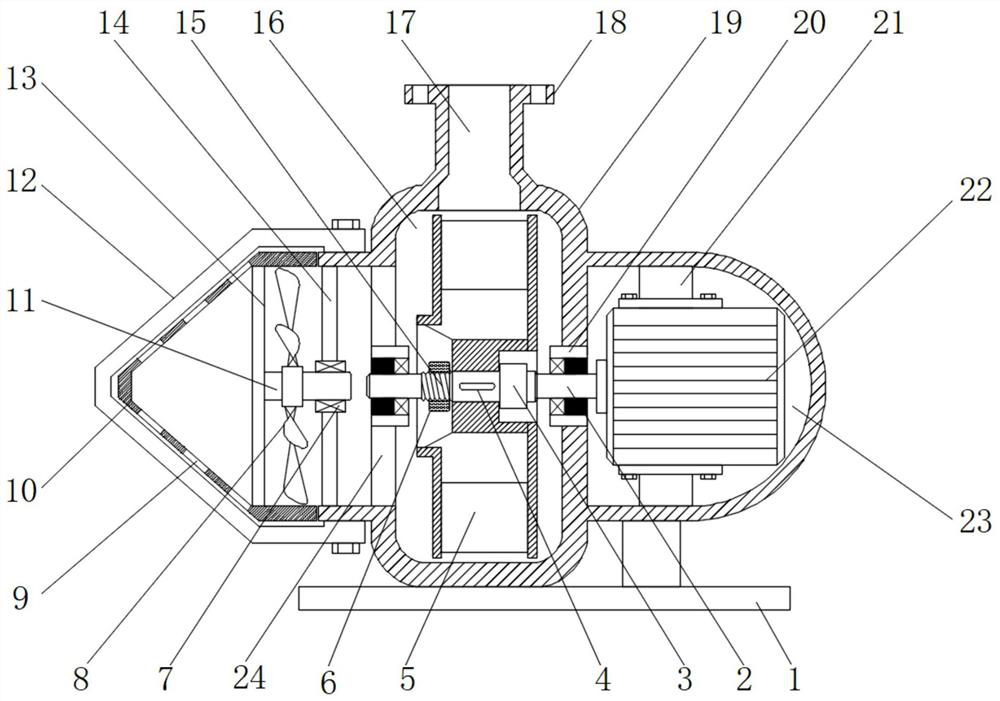

[0032] see Figure 1-4 , in an embodiment of the present invention, a water pump based on carbon-graphite bearings and ceramic bearings includes a base plate 1, a pump casing 19 is installed on the upper end surface of the bottom plate 1, and a pump chamber 16 is provided in the middle of the pump casing 19. The pump The right side of the casing 19 is provided with an installation chamber 23, and the side of the pump casing 19 far away from the installation chamber 23 is connected with a water inlet cylinder 26 communicating with the inside of the pump chamber 16. A water filter assembly for filtering water;

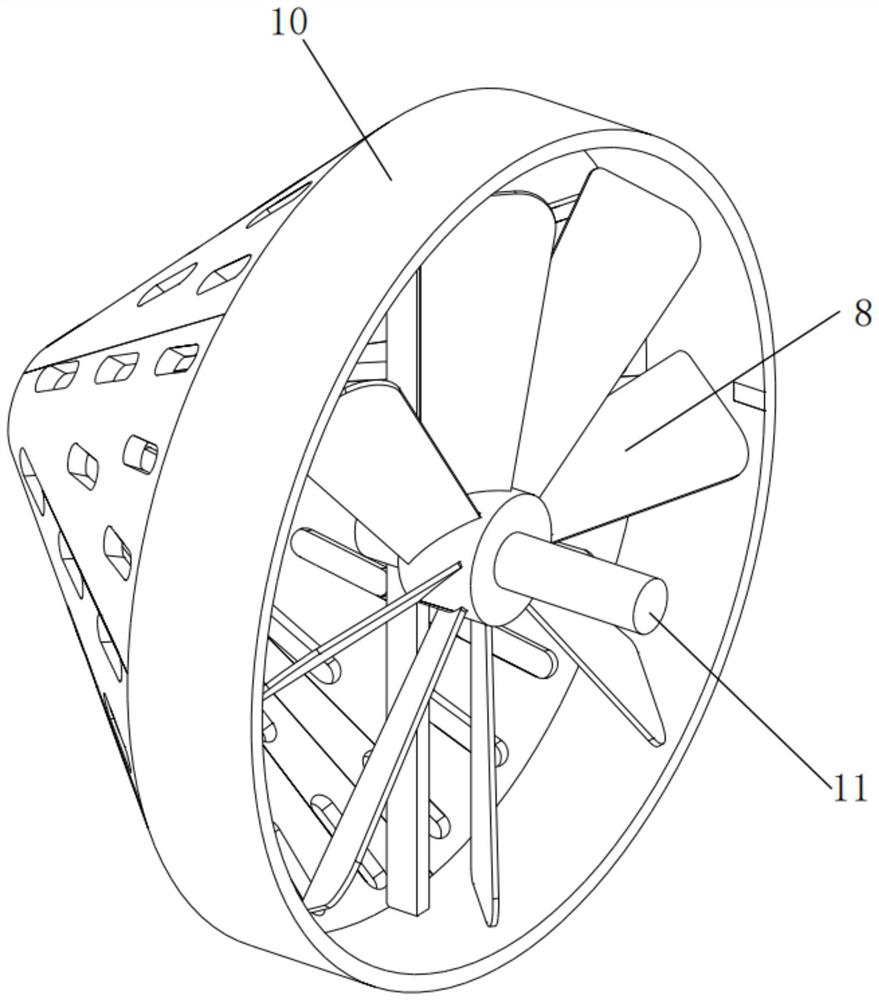

[0033] The water filtering assembly includes a mounting frame 14, which is fixedly connected to the end of the water inlet cylinder 26 away from the pump casing 19, and the middle position of the mounting frame 14 is provided with a rotating sleeve 7, and the rotating sleeve 7 is rotationally connected with The rotating shaft 11 is fixedly connected with the blade 8, an...

Embodiment 2

[0042] see Figure 5-6 The difference from Embodiment 1 is that the anti-blocking assembly also includes a mounting hole block 29, and the two mounting hole blocks 29 are fixedly connected to the positions of the upper end and the lower end of the water inlet cylinder 26 respectively, and the two mounting hole blocks 29 are fixed Connected with a V-shaped brush frame 31, the V-shaped brush frame 31 is provided with bristles 30 on one side close to the water filter cover 10; the bristles arranged on the V-shaped brush frame 31 can make cleaning easier It is clean and effectively prevents sundries from clogging the water hole 9 .

[0043] The working principle of the present invention is: when the present invention is in use, the driving motor 22 drives the impeller 5 to rotate, so that the water inlet cylinder 26 and the water outlet 17 generate a pressure difference, and the water is sucked from the water hole 9 on the water filter cover 10 and passed through the water inlet. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com