Automobile cooling performance testing system and method

A heat dissipation performance and testing method technology, which is applied in the testing of machines/structural components, measuring devices, aerodynamic testing, etc., can solve the problems of low test accuracy and incomplete testing, and increase the application range and wind field uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

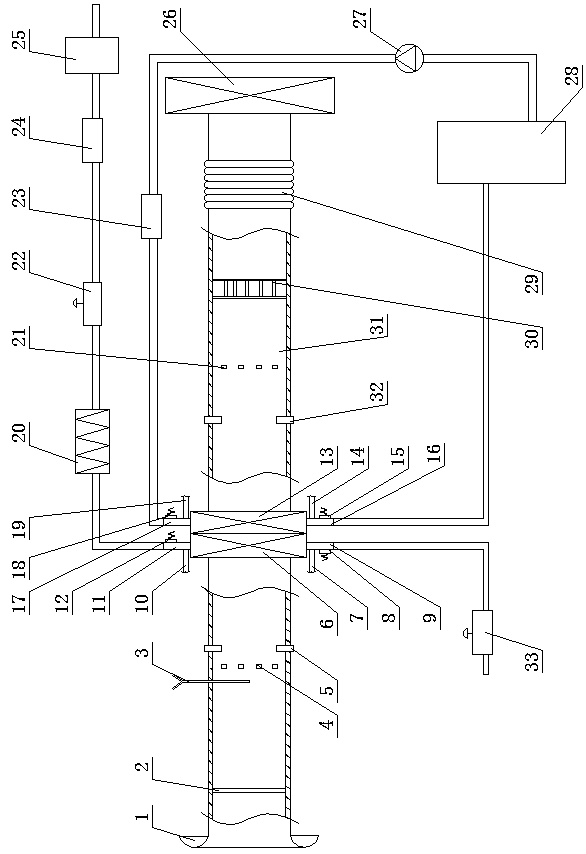

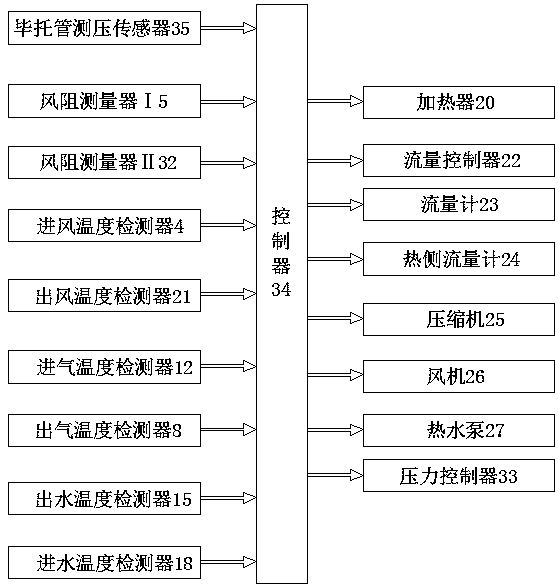

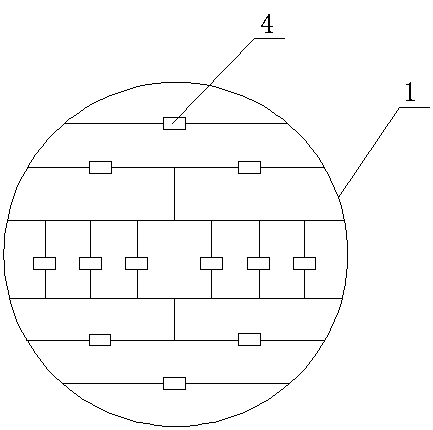

[0052] as attached figure 1 And attached figure 2 As shown, the automobile heat dissipation performance testing system of the present invention includes a wind tunnel, and the wind tunnel includes an air inlet tube 1 and an air outlet tube 31 docked on the left and right sides, and an air inlet tube 1 and an air outlet tube 31 are arranged between the air inlet tube 1 and the air outlet tube 31 for use with water-cooled heat dissipation. The water inlet pipe 17 and the water outlet pipe 16 connected to the part 13 and the air inlet pipe 11 and the air outlet pipe 9 for connecting with the air-cooled heat sink 6 are installed in the water inlet pipe 17, the water outlet pipe 16, the air inlet pipe 11 and the air outlet pipe 9. Temperature detector, the air inlet tube 1 is divided into an air inlet end with a concentrating effect and an air outlet end with a flow stabilization effect; the air outlet tube 31 is an outlet tube with a flow stabilization effect; the outlet of the a...

Embodiment 2

[0062] as attached Figure 4 As shown, this embodiment is a further improvement on the basis of Embodiment 1. The difference between this embodiment and Embodiment 1 is: the air outlet end of the air inlet cylinder 1 is sealed but connected with a diffusion transition section 36 with a diffusion angle of 8°. The air inlet end of the air outlet tube 31 is sealed butted with a convergent transition section 37 with a convergence angle of 15°, the large mouth end of the diffuse transition section 36 and the large mouth end of the convergent transition section 37 are docked left and right, and the air-cooled heat sink 6 and the water-cooled heat sink 13 is sequentially installed between the diffusion transition section 36 and the convergence transition section 37 from left to right.

[0063] Through the cooperation of the diffusion transition section 36 and the convergence transition section 37, performance tests on various types of radiators and intercoolers can be realized.

[0...

Embodiment 3

[0066] In this embodiment, the standard of terms adopts the following definitions:

[0067] Wind tunnel: It is used to install water-cooled heat sink 13, air-cooled heat sink 6 and sensors, and has the function of measuring and recording test data, and is a measurement and test device that meets the test requirements.

[0068] Water-cooled radiator 13: a device installed in the water circulation system of the automobile engine to ensure the normal operation of the engine and provide cooling and heat dissipation functions for the engine.

[0069] Air-cooled heat sink 6: Installed between the engine and the intake manifold, it is a device for reducing the output air temperature of the supercharger through air cooling.

[0070] Liquid-air temperature difference: the difference between the water inlet temperature of the water-cooled heat sink 13 and the air inlet temperature of the cold side of the water-cooled heat sink 13 .

[0071] Air-air temperature difference: the differenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com