Method for preparing double-cladding active fiber

A double-clad, optical fiber technology, applied in clad optical fiber, multi-layer core/clad optical fiber, glass manufacturing equipment, etc., can solve problems such as easy generation of air bubbles, poor weather resistance, fracture, etc., to improve weather resistance and improve Quality, the effect of overcoming coating aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

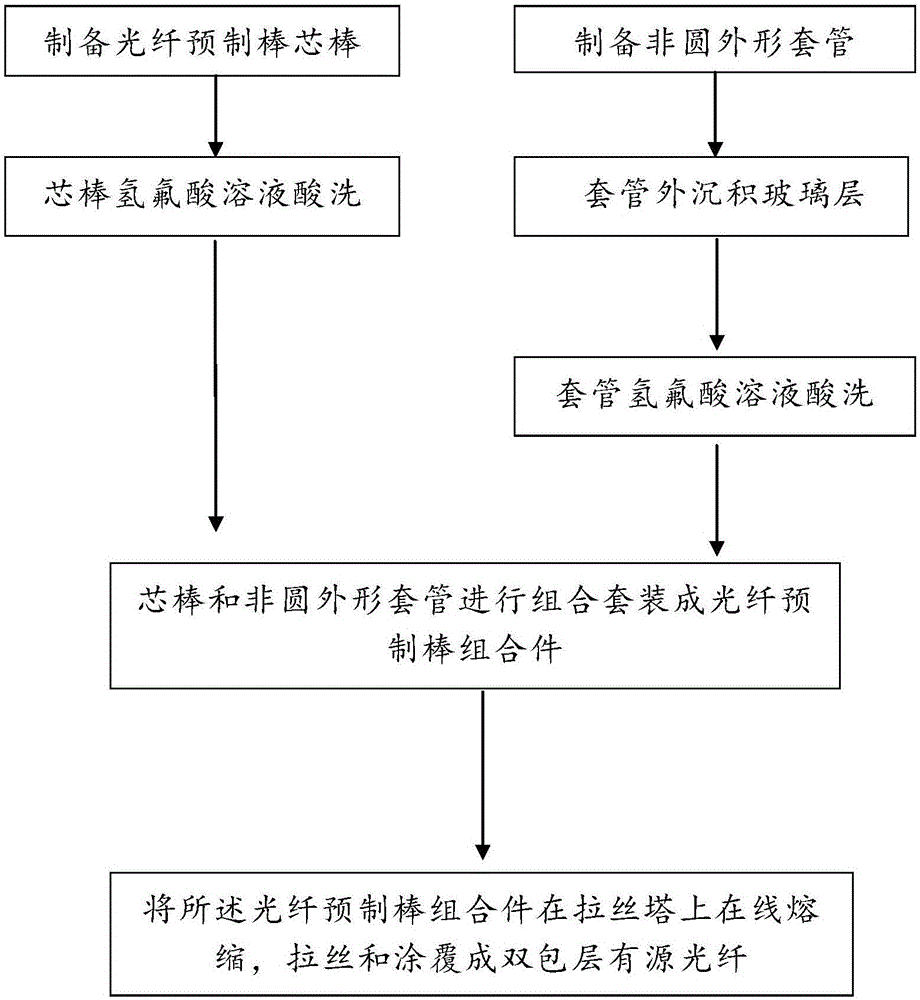

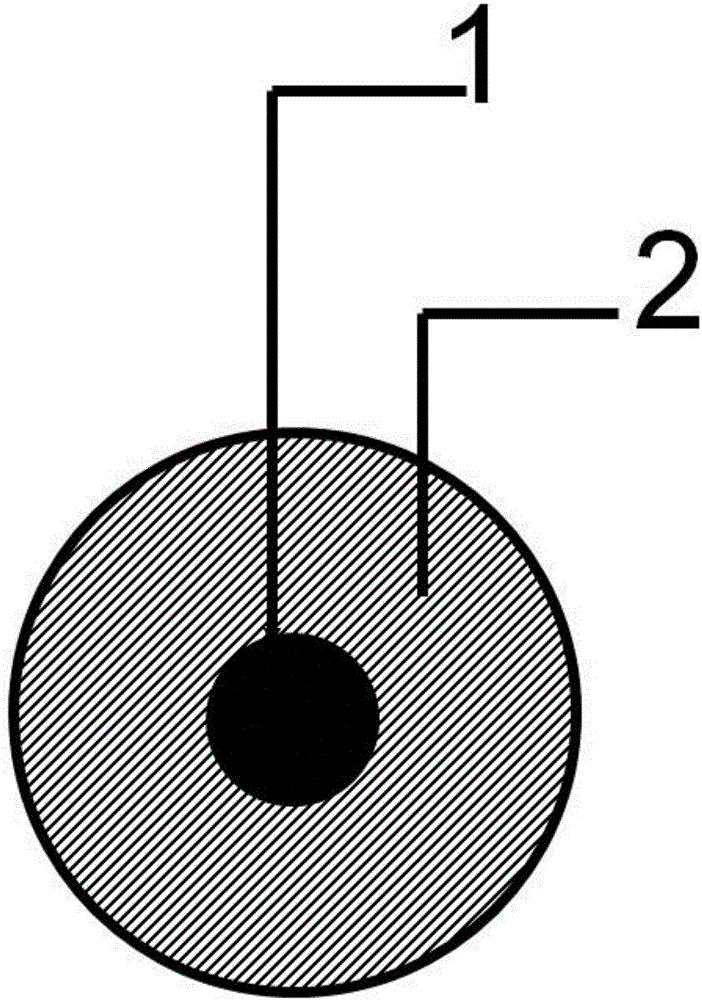

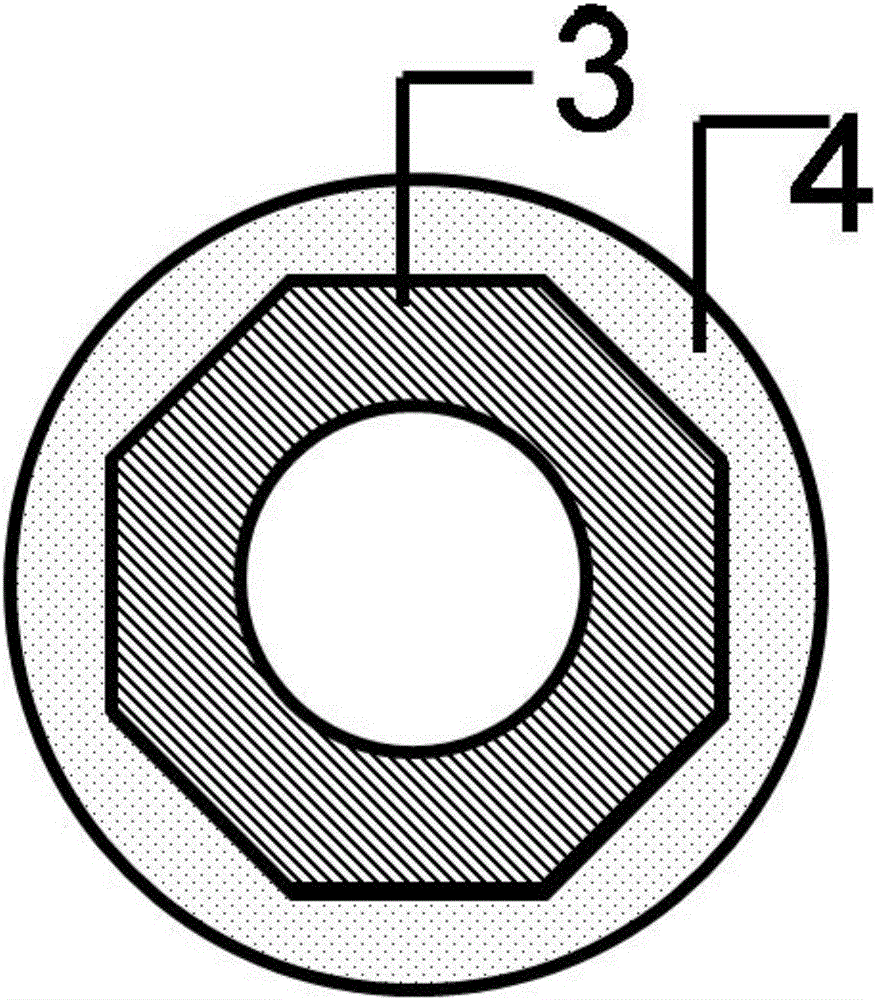

[0035] The embodiment of the present application provides a method for preparing a double-clad active optical fiber to solve the technical problems in the prior art that the inner coating is easy to age, has poor weather resistance, and easily generates bubbles, impurities, fractures and defects during the wire drawing process; Improve the technical effect of weather resistance and product quality.

[0036] In order to better understand the above technical solutions, the above technical solutions will be described in detail below in conjunction with the accompanying drawings and specific implementation methods. It should be understood that the embodiments of the present invention and the specific features in the embodiments are detailed descriptions of the technical solutions of the present application. , rather than limiting the technical solutions of the present application, the embodiments of the present application and the technical features in the embodiments can be combin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com