Multi-mode waveguide 90-degree turning array chip

An array chip and waveguide technology, applied in the field of multimode waveguide 90° steering array chips, can solve the problems that hinder the miniaturization of active optical cables, low cost of integration, high reliability, high cost of mold opening, optical aging, etc., and achieve Conducive to optical integration, reduce joining and mounting procedures, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

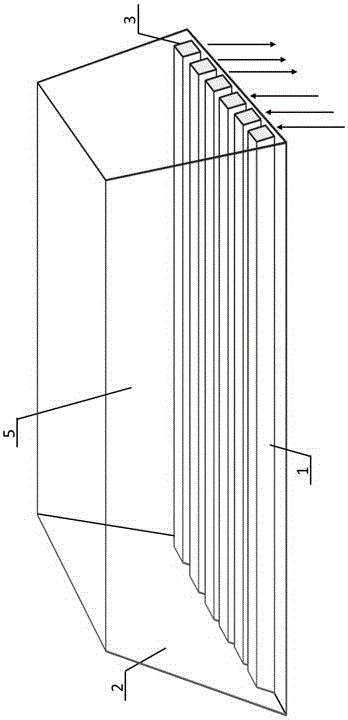

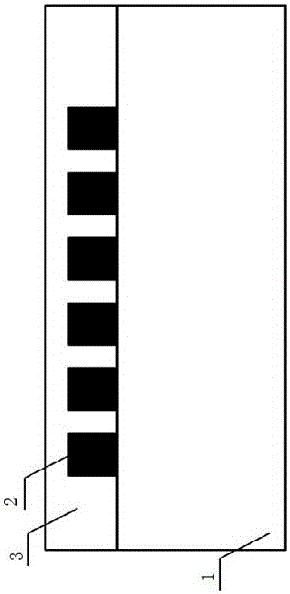

[0022] Such as Figure 1-3 As shown, a multimode waveguide 90° steering array chip includes a chip body 5 , the chip body 5 includes a substrate 1 , a waveguide 2 and a cladding 3 , and the cladding 3 wraps the waveguide 2 on the substrate 1 . The material of the substrate 1 is pure quartz glass. The material of the waveguide 2 is silicon dioxide doped with Ge. The cladding layer 3 is made of silicon dioxide doped with B and P. The cross section of the waveguide can be adjusted according to the specific situation. The thickness of the cladding layer 3 is 15 μm, and the upper and lower ranges can be adjusted.

[0023] The waveguides 2 are arranged in parallel and the intervals between the waveguides 2 are equal. The number of the waveguides and the distance between the waveguides can be adjusted according to specific conditions.

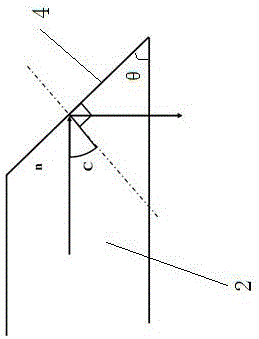

[0024] And one end surface of the waveguide 2 is a total reflection surface 4 . The inclination angle of the total reflection surface 4 is θ, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com