Multilayer wire structure of printed circuit board, magnetic element and manufacturing method thereof

A technology for printed circuit boards and manufacturing methods, which is applied in the direction of printed circuit manufacturing, printed circuit components, printed circuits, etc., can solve the problems of increasing the size of the overall printed circuit board, achieve the elimination of electroplating process, save process steps, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

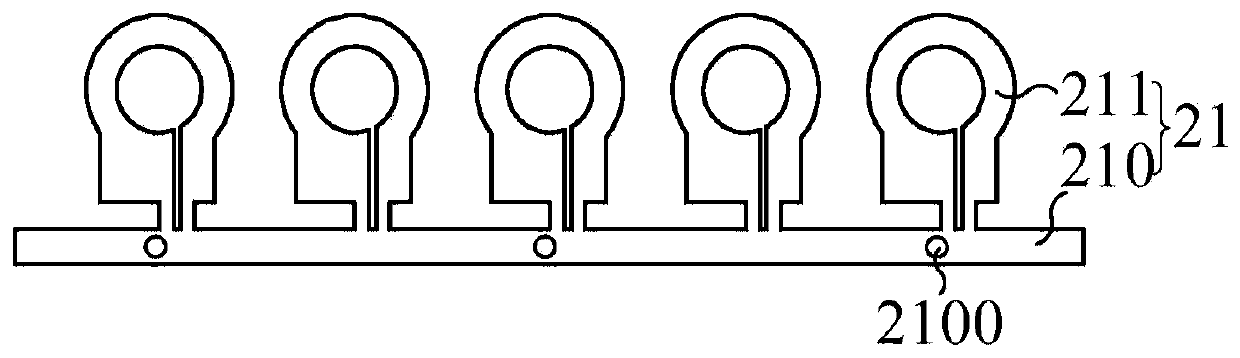

[0064] See Figure 2a-2c , which is a schematic diagram of the process of the PCB multilayer wire structure manufacturing method developed in this case to improve the lack of common means. First, as Figure 2a , which first defines a plurality of wire structures 21 in the form of punching or etching, each wire structure 21 includes a plurality of subunits 211 and connection bars 210 respectively connected to the plurality of subunits 211, and the connection bars 210 can also be With the positioning hole 2100, the shapes of the plurality of sub-units 211 may be the same or slightly different, and each lead structure 21 is integrally formed by stamping or etching. The plurality of wire structures 21 above can be completed with copper conductors or other metal or alloy materials, and can be additionally browned to increase surface roughness.

[0065] see next Figure 2bAn insulating layer 22 is respectively provided between the above-mentioned wire structures 21, and the above-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com