Spraying tower packing for absorbing waste gases in production of sesame indicum extract

An extract, spray tower technology, applied in the field of spray tower packing, can solve problems such as unsatisfactory effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The spray tower packing used to absorb waste gas in the production of sesame extract is prepared by the following steps:

[0025] 1) Preparation of raw materials: prepare 90kg of fiber silk and 10kg of mango peel;

[0026] 2) Treatment of mango peel:

[0027] ① Enzymatic hydrolysis treatment: After crushing or breaking, add 2-3 weight of purified water equivalent to mango peel, heat to 50℃ for 10 minutes to obtain paste slurry, adjust pH to 4-5, add 0.05% weight of paste slurry Part of the pectin-cellulose complex enzyme and 0.001 part by weight of mannitol were subjected to enzymolysis for 60 minutes, and the temperature was maintained at 40-45°C to obtain the enzymatic hydrolysis solution;

[0028] ②Steam explosion: Put the material obtained in step ① into the steam explosion tank, the explosion pressure is 3.0Mpa, and the pressure holding time is maintained at 200s;

[0029] ③Decoction: Add the material obtained in step ② to the same weight of purified water and decoct it twi...

Embodiment 2

[0034] The spray tower packing used to absorb waste gas in the production of sesame extract is prepared by the following steps:

[0035] 1) Preparation of raw materials: prepare 92kg of fiber silk and 8kg of mango peel;

[0036] 2) Treatment of mango peel:

[0037] ① Enzymatic hydrolysis treatment: After crushing or breaking, add purified water equivalent to 2-3 weight of mango peel, heat to 60℃ for 5 minutes to obtain paste slurry, adjust pH to 4-5, add 0.1% weight of paste slurry Part of the pectin-cellulose complex enzyme and 0.001 part by weight of mannitol were subjected to enzymatic hydrolysis for 50 minutes, and the temperature was maintained at 40-45°C to obtain an enzymatic hydrolysis solution;

[0038] ②Steam explosion: Put the material obtained in step ① into the steam explosion tank, the explosion pressure is 3.5Mpa, and the pressure holding time is maintained at 150s;

[0039] ③Decoction: Add the material obtained in step ② to the same weight of purified water and decoct i...

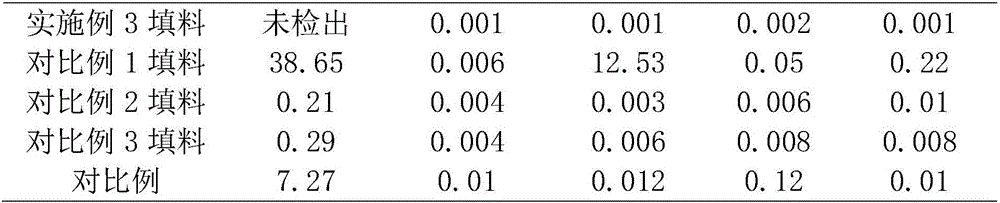

Embodiment 3

[0044] The spray tower packing used to absorb waste gas in the production of sesame extract is prepared by the following steps:

[0045] 1) Preparation of raw materials: prepare 95kg of fiber silk and 5kg of mango peel;

[0046] 2) Treatment of mango peel:

[0047] ① Enzymatic hydrolysis treatment: After crushing or breaking, add purified water equivalent to 2-3 weight of mango peel, heat to 55°C for 10 minutes to obtain paste slurry, adjust pH to 4-5, add 0.1% weight of paste slurry Part of the pectin-cellulose complex enzyme and 0.001 part by weight of mannitol were subjected to enzymolysis for 60 minutes, and the temperature was maintained at 40-45°C to obtain the enzymatic hydrolysis solution;

[0048] ②Steam explosion: Put the material obtained in step ① into the steam explosion tank, the explosion pressure is 3.5Mpa, and the pressure holding time is maintained at 180s;

[0049] ③Decoction: Add the material obtained in step ② to the same weight of purified water and decoct it twic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com