High-temperature heating vacuum furnace for carbonization catalysis and graphitization purification

A high-temperature heating and vacuum furnace technology, which is applied in the fields of carbon compounds, chemical instruments and methods, and inorganic chemistry, can solve the problem of difficult customers to provide A-grade graphite high thermal conductivity film, and achieve uniform heating and smooth appearance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

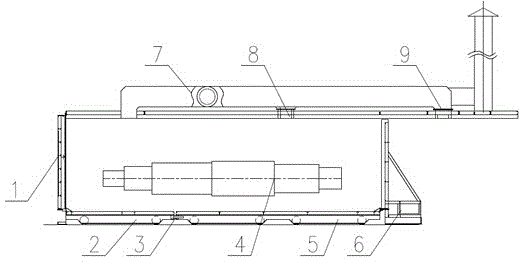

[0011] Depend on figure 1 It is known that a high-temperature heating vacuum furnace for carbonization catalysis and graphitization purification consists of a lifting device 1, a bracket 2, an induced draft fan 3, a burner 4, a furnace body 5, parts 6, high-strength castables 7, refractory bricks 8, and a furnace The furnace body 5 is composed of a high-strength castable 7, a refractory brick 8, and a furnace door 9 from the inside to the outside. The furnace body 5 is a square furnace body, and the furnace body 5 has two symmetrical squares on the left and right. Hole, bracket 2 is arranged on furnace body 5 tops, and described square hole is heat treatment parts inlet and outlet, and furnace door 9 is installed on the outside of square hole. The burner 4 is a regenerative burner, and two pairs of regenerative burners are arranged on the top of the furnace body 5, and the regenerative burner is automatically adjusted according to the temperature in the furnace. The induced d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com