Chloride ion adsorption agent for reinforced concrete structure and preparation method thereof

A reinforced concrete and adsorbent technology, applied in the field of building materials, can solve the durability hazards of marine concrete structures, reduce the mechanical properties such as bond strength, and reduce the effective cross-section, so as to improve the working performance and increase the density , Improve the effect of density and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

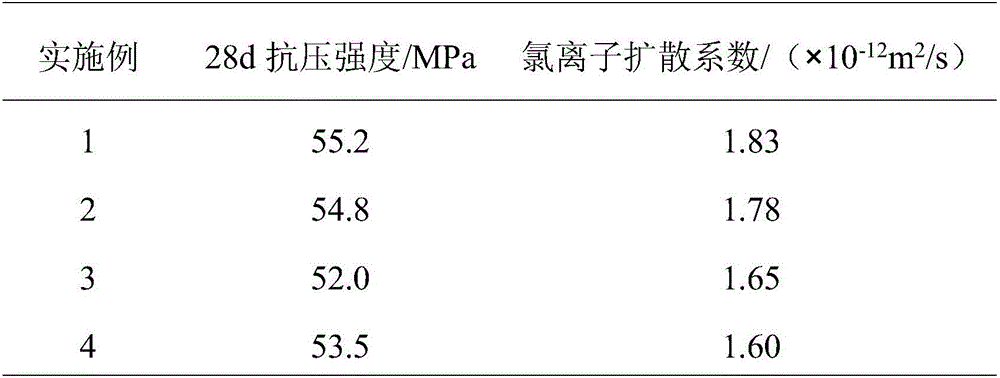

Examples

Embodiment 1

[0016] A chlorine ion adsorbent for reinforced concrete structures comprises the following components in mass percentage: 20% of floating beads, 18% of mesoporous molecular sieves, nano-SiO 2 14%, regenerated activated carbon 8%, calcium aluminate powder 5%, calcined kaolin 15%, ferric aluminate cement clinker 20%.

[0017] The preparation method of above-mentioned reinforced concrete structure chlorine ion adsorbent comprises the following steps:

[0018] 1) Put the aluminate cement clinker in the mill and grind until the specific surface area is 400m 2 / kg;

[0019] 2) The floating beads, mesoporous molecular sieve, nano-SiO 2 , regenerated activated carbon, calcium aluminate powder, calcined kaolin and ferroaluminate cement clinker are weighed according to the above ratio, poured into a mixer, and mixed evenly to obtain a chloride ion adsorbent for reinforced concrete structures.

[0020] According to the concrete mix ratio: cement 400kg / m 3 , sand 800kg / m 3 , gravel 1...

Embodiment 2

[0023] A chlorine ion adsorbent for reinforced concrete structures comprises the following components in mass percentage: 24% of floating beads, 14% of mesoporous molecular sieves, nano-SiO 2 12%, regenerated activated carbon 6%, calcium aluminate powder 9%, calcined kaolin 18%, iron aluminate cement clinker 17%.

[0024] The preparation method of above-mentioned reinforced concrete structure chlorine ion adsorbent comprises the following steps:

[0025] 1) Put the aluminate cement clinker in the mill and grind it until the specific surface area is 450m 2 / kg.

[0026] 2) The floating beads, mesoporous molecular sieve, nano-SiO 2 , regenerated activated carbon, calcium aluminate powder, calcined kaolin and ferroaluminate cement clinker are weighed according to the above ratio, poured into a mixer, and mixed evenly to obtain a chloride ion adsorbent for marine reinforced concrete structures.

[0027] According to the concrete mix ratio: cement 400kg / m 3 , sand 800kg / m 3 , ...

Embodiment 3

[0030] A chlorine ion adsorbent for reinforced concrete structures comprises the following components in mass percentage: 27% of floating beads, 11% of mesoporous molecular sieves, nano-SiO 2 10%, 5% recycled activated carbon, 12% calcium aluminate powder, 22% calcined kaolin, 13% iron-aluminate cement clinker.

[0031] The preparation method of above-mentioned reinforced concrete structure chlorine ion adsorbent comprises the following steps:

[0032] 1) Put the aluminate cement clinker in the mill and grind it until the specific surface area is 480m 2 / kg.

[0033] 2) The floating beads, mesoporous molecular sieve, nano-SiO 2 , regenerated activated carbon, calcium aluminate powder, calcined kaolin and ferroaluminate cement clinker are weighed according to the above ratio, poured into a mixer, and mixed evenly to obtain a chloride ion adsorbent for marine reinforced concrete structures.

[0034] According to the concrete mix ratio: cement 400kg / m 3 , sand 800kg / m 3 , gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com