Antibacterial stool cover and preparation method thereof

The technology of a toilet cover and its manufacturing method is applied in the field of sanitary ware, which can solve the problems of high production cost, inability to use the toilet, inconvenience, etc., and achieve the effects of low production cost, good sterilization effect and good killing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

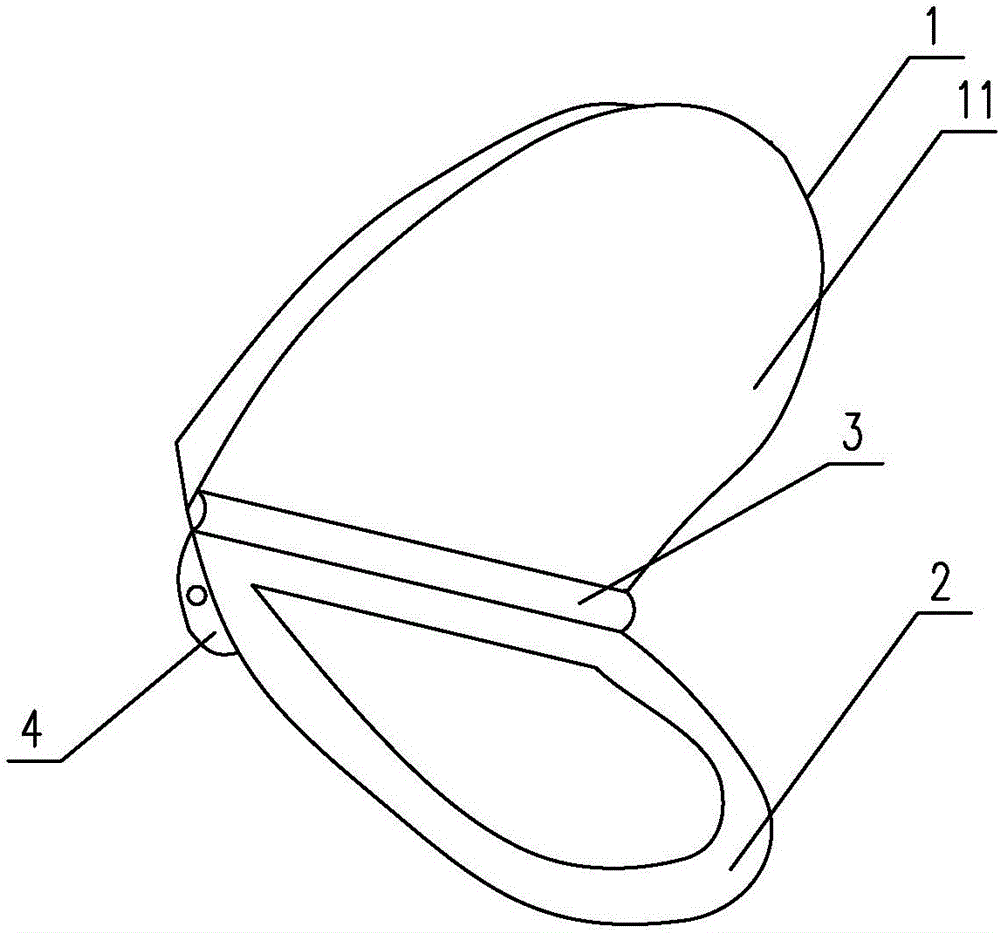

[0033] An antibacterial toilet cover, the toilet cover body 1 and seat cushion 2 are made of alloy material, the chemical composition of the alloy material used in the toilet cover body 1 and seat cushion 2 is as follows: Al 42%, Zr 38%, Cu 8%, Co 4%, Mg 2%, Si 3%, Ag 3%;

[0034] The coating of the antibacterial coating layer is composed of the raw materials of the following components: 13 parts of nano-titanium dioxide, 15 parts of nano-zinc oxide, 4 parts of polyether polyol, 38 parts of silicone high-strength resin, 4 parts of polyaminopropyl biguanide, 26 parts of distilled water .

[0035] The specific steps of making the above-mentioned antibacterial toilet seat cover are as follows:

[0036] Step 1, making the alloy material into the shape of the toilet seat, and cleaning the surface;

[0037] Step 2, immerse the cleaned toilet cover in ethanol and clean it again with ultrasonic waves to remove tiny impurities on the surface of the toilet cover;

[0038] Step 3, ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com