Fiber refining process

A fiber and process technology, applied in the field of fiber refining process, can solve the problems of increasing fiber manufacturing cost, waste of lye, waste of water resources, etc., and achieve the effects of improving utilization rate, reducing production cost, and reducing usage amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

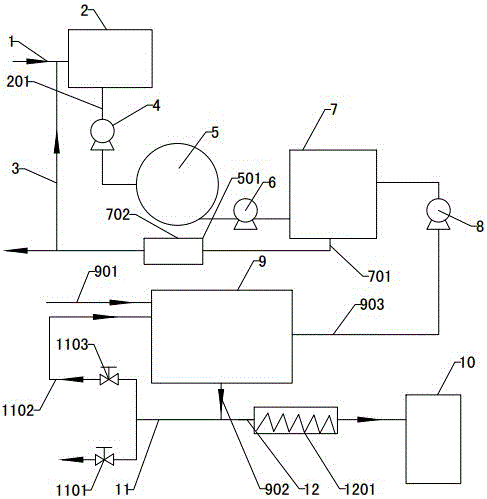

[0051] The rinsing and drying device includes a primary dehydrator 9 and a secondary dehydrator 13. The upper part of the primary dehydrator 9 and the secondary dehydrator 13 are provided with a rinsing water inlet pipe 901 and a slurry input pipe 903, and the lower part is provided with a discharge pipe. Pipeline, discharge pipeline is divided into rinsing water discharge pipe 11 and fiber discharge pipe 12; The fiber discharge pipe 12 of primary dehydrator 9 is connected to the feed end of secondary dehydrator 13, and the fiber discharge pipe 12 of secondary dehydrator 13 The rinsing water discharge pipe 11 is respectively connected to the rinsing water discharge pipe 11 connected to the outlet of the primary dehydrator 9 and the rinsing water circulation pipe 1102 provided on the upper part of the primary dehydrator 9 through the sedimentation and separation device.

[0052] When in use, after several times of rinsing, the liquid discharged in the secondary dehydrator 13 is ...

Embodiment 3

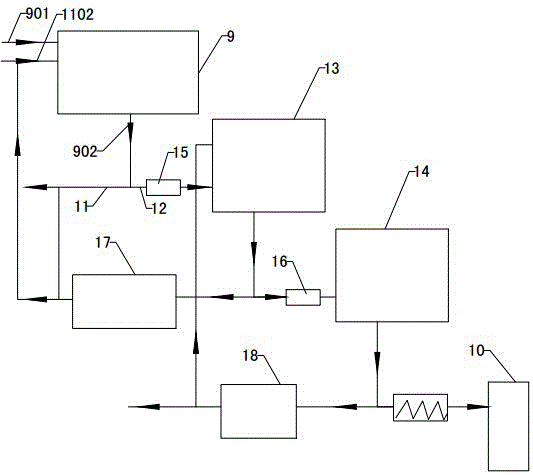

[0054] Refer to attached figure 2 : The rinsing and drying device comprises more than two dehydrating machines connected in series in sequence, the upper part of the dehydrating machine is provided with a rinsing water inlet pipe 901 and a slurry input pipe 903, and the lower part of the primary dehydrating machine 9 is provided with a discharge pipeline, and the discharge pipeline is divided into The rinsing water discharge pipe 11 and the fiber discharge pipe 12, the fiber discharge pipe 12 is connected to the dryer 10 through the conveying pipeline; the upper part of a dehydrator in front is provided with a rinsing water circulation pipe 1102, and a dehydrator in the back is arranged The rinsing water discharge pipes 11 are respectively connected to the rinsing water circulation pipes 1102 of the previous dehydrator through the sedimentation and separation device.

[0055] As shown in the figure, there are a primary dehydrator 9, a secondary dehydrator 13 and a tertiary de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com