Preparation method of cyhalothrin and chlorfluazuron microcapsule suspension-suspension and microcapsule suspension-suspension

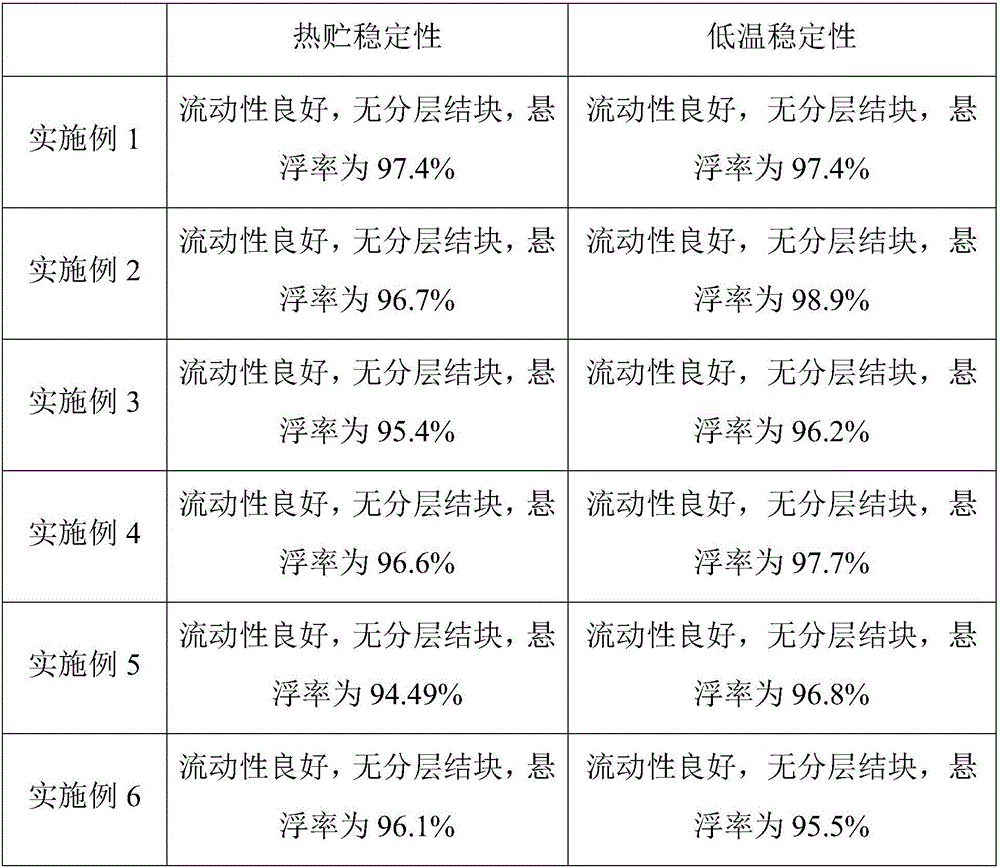

A technology of high-efficiency cyhalothrin and microcapsule suspension, which is applied in the field of pesticides, can solve the problems of difficult to meet the preparation requirements of pesticides for the prevention and control of crop pests, poor pest effect, and difficult storage, etc., to achieve reduced dosage, good storage stability, The effect of reducing the number of medications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

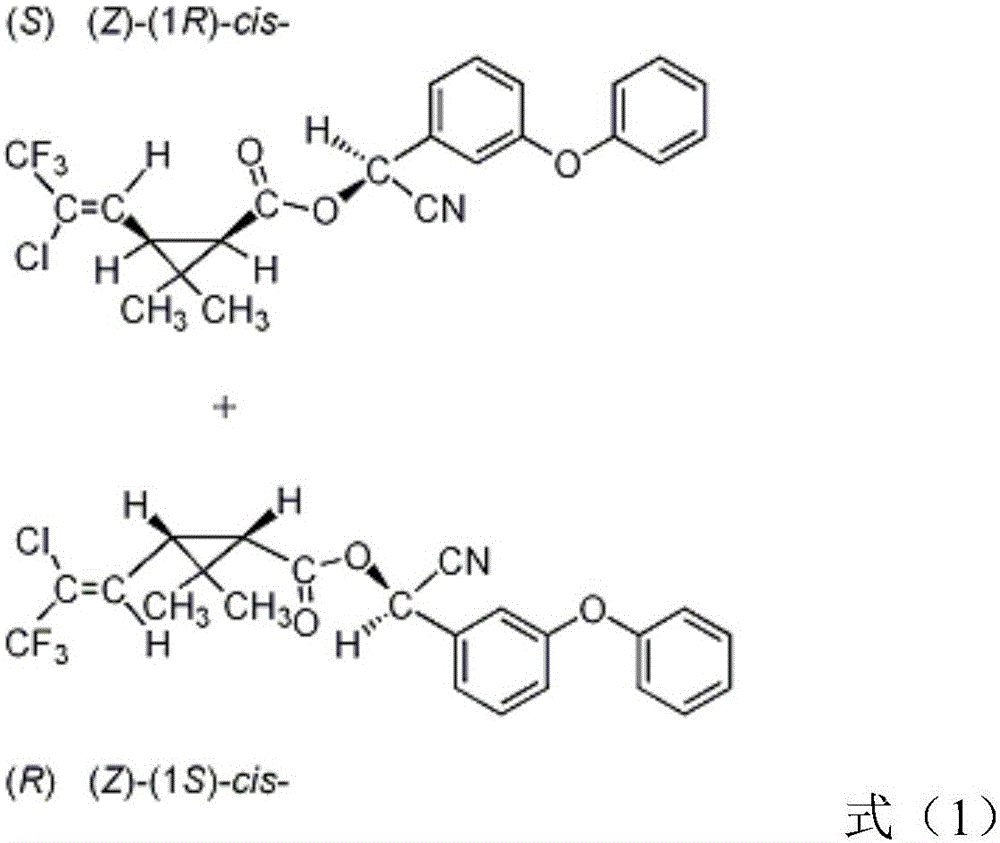

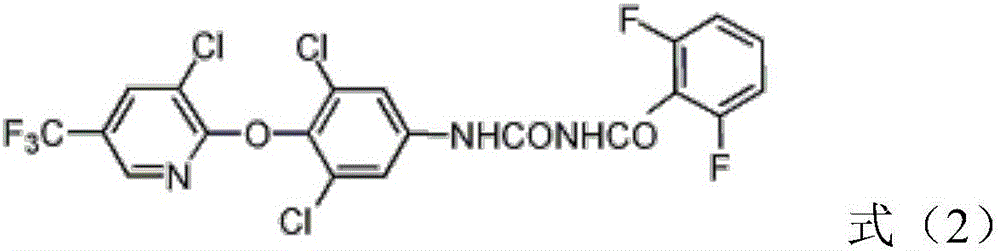

[0019] The first aspect of the present disclosure: provide a preparation method of lambda-cyhalothrin·chlorfluazuron microcapsule suspension-suspension agent, the method comprises the following steps: a, mixing amino resin prepolymer aqueous solution with lambda-cyhalothrin The ester emulsifiable oil is (1-5): 1 mixed by weight to obtain the first material; b, the first material obtained in step a is mixed with a buffer solution to obtain the second material, and the pH of the second material value is 5-7; c, the second material obtained in step b is mixed with an acidic solution to obtain a third material, and the pH value of the third material is 3-4; d, at a temperature of 40-70 Under the condition of ℃, the third material obtained in step c was processed for 2-7 hours to obtain the fourth material; e, the fourth material obtained in step d was mixed with chlorfluazuron suspending agent and emulsifying dispersant according to The weight ratio is 1:(0.1-1):(0.01-2) and mixed...

Embodiment 1

[0038] Mix melamine, formaldehyde and water, and react for 1.5 hours at a pH value of 8 and a temperature of 70°C to obtain a melamine-formaldehyde resin prepolymer aqueous solution, wherein the molar ratio of formaldehyde to melamine is 1:0.5, and water and formaldehyde The weight ratio is 2.8:1.

[0039] Evenly mix lambda-cyhalothrin, 200# solvent oil and sorbitan monostearate polyoxyethylene ether to obtain lambda-cyhalothrin emulsifiable concentrate, wherein, said lambda-cyhalothrin, 200 #The weight ratio of solvent oil and sorbitan monostearate polyoxyethylene ether is 1:2.5:0.05.

[0040] Mix the melamine-formaldehyde resin prepolymer aqueous solution and efficient cyhalothrin emulsifiable concentrate at a weight ratio of 4:1 at a stirring speed of 2000 rpm to obtain the first material; then at room temperature, adjust the pH value to 4.5. The acetic acid-sodium acetate buffer solution whose total concentration of the buffer pair is 2% by weight is uniformly added to th...

Embodiment 2

[0044] Mix melamine, formaldehyde and water and react for 1.5 hours at a pH value of 8 and a temperature of 70°C to obtain a melamine-formaldehyde resin prepolymer aqueous solution, wherein the molar ratio of formaldehyde to melamine is 1:1, and water and formaldehyde The weight ratio is 3.5:1.

[0045] Mix lambda-cyhalothrin, 150# solvent oil and sodium lignosulfonate evenly to obtain lambda-cyhalothrin emulsifiable concentrate, wherein the lambda-cyhalothrin, 150# solvent oil and lignosulfonic acid The weight ratio of sodium is 1:0.5:0.1.

[0046] Mix melamine-formaldehyde resin prepolymer aqueous solution and efficient cyhalothrin emulsifiable concentrate at a weight ratio of 2:1 at a stirring speed of 1500 rpm to obtain the first material; then at room temperature, adjust the pH value to 3. The acetic acid-sodium acetate buffer solution whose total concentration of the buffer pair is 2% by weight is uniformly added to the above-mentioned first material within 1 hour, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com