Method for removing fishy smell of spirulina with quercetin

A technology of spirulina and quercetin, applied in the field of fishy smell removal, can solve the problems of harshness, difference in effect of fishy smell removal, unsatisfactory effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

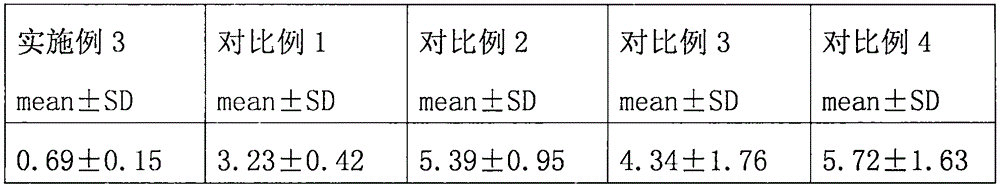

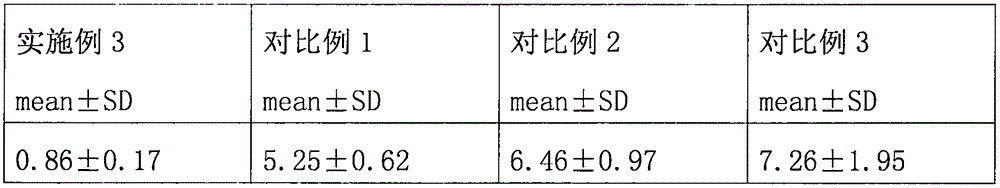

Examples

Embodiment 1

[0012] A method for removing the fishy smell of spirulina with quercetin, comprising the steps of: (1) taking spirulina powder by weighing, adding 50 times of distilled water for stirring, and then passing through a colloid mill; (2) using cellulase and pectinase enzyme solution, the temperature is 25°C, and after the action time is 1.5h, the enzyme is deactivated and filtered; (3) in the enzymolysis solution

[0013] Add ethanol, add quercetin, shake at 40°C for 1 hour; (4) add maltodextrin, and carry out spray drying. (5) Carry out tabletting process, form spirulina tablet. The dosages of the cellulase and pectinase are respectively 200U / ML spirulina solution. The enzyme is inactivated at 80° C. for 10 minutes. The spray drying inlet temperature is 180°C and the outlet temperature is 60°C.

Embodiment 2

[0015] A method for removing the fishy smell of spirulina by quercetin, comprising the steps of: (1) taking spirulina powder by weighing, adding 100 times of distilled water for stirring, and then passing through a colloid mill; (2) using cellulase and pectinase enzyme (3) Add ethanol to the enzymolysis solution, add quercetin, and shake at 45°C for 2 hours; (4) Add maltodextrin and spray dry. Step (5) carries out tabletting treatment, forms spirulina tablet. The dosages of the cellulase and pectinase are respectively 400U / ML spirulina solution. The enzyme is inactivated at 100° C. for 5 minutes. The spray drying inlet temperature is 210°C and the outlet temperature is 80°C.

Embodiment 3

[0017] A method for removing the fishy smell of spirulina with quercetin, comprising the steps of: (1) taking spirulina powder by weighing, adding 80 times of distilled water for stirring, and then passing through a colloid mill; (2) using cellulase and pectinase enzyme (3) add ethanol to the enzymolysis liquid, add quercetin, and shake at 42°C for 1.5 hours; (4) add maltodextrin, carry out Spray dry. (5) Carry out tabletting process, form spirulina tablet. The dosages of the cellulase and pectinase are respectively 350U / ML spirulina solution. The enzyme is inactivated at 90° C. for 8 minutes. The spray drying inlet temperature is 200°C and the outlet temperature is 70°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com