Preparation technology of premna microphylla bean curds

A preparation process and technology of rotten bean curd, which is applied in the field of rotten tofu preparation technology, can solve the problems of dark color, short storage period, easy dehydration of rotten tofu, etc., and achieve the goal of improving relative purity, ensuring quality, and increasing production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

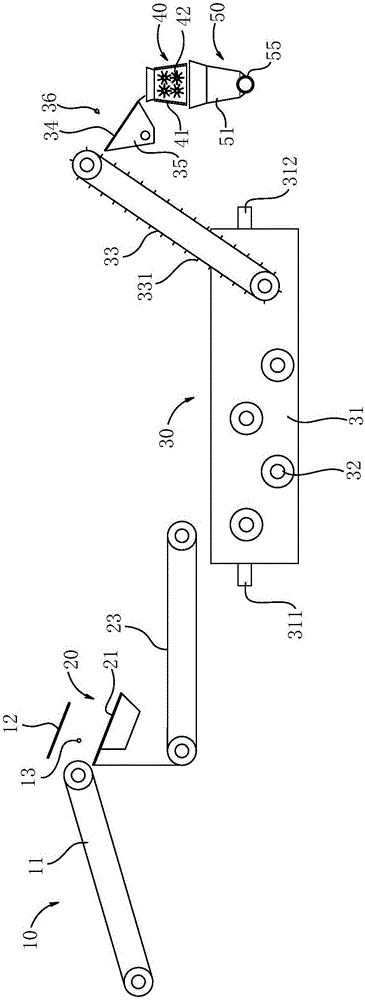

[0053] A kind of preparation technology of curd tofu, comprises the following operations:

[0054] S1: Place the picked fresh leaves of rotten leaves on a bamboo mat and let them naturally spread out to adjust to wither;

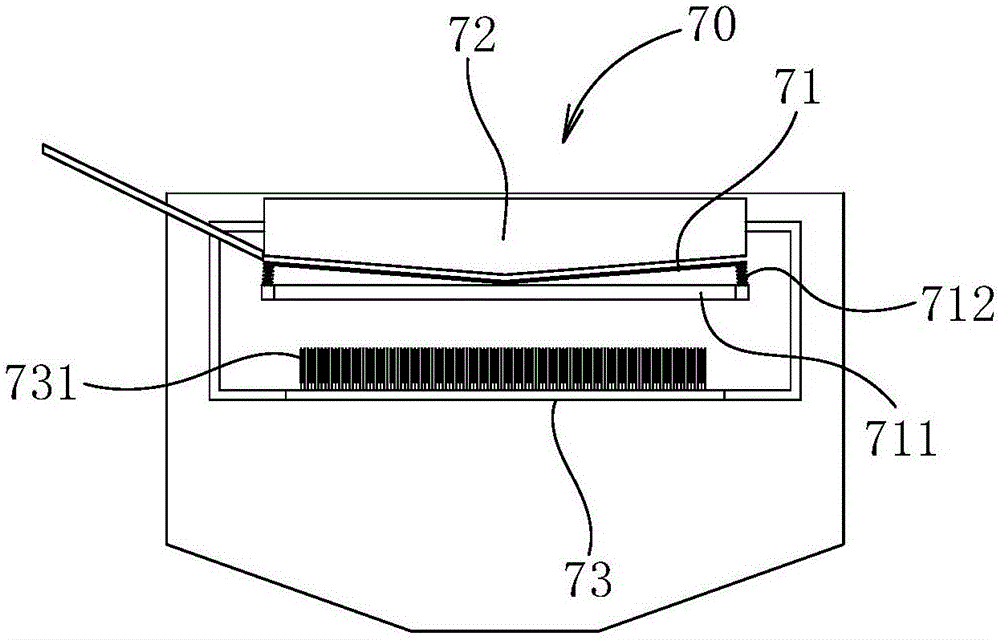

[0055] S2: Carry out greening treatment on the rotten maidservant leaves spread naturally;

[0056] S3: cooling and reviving the rotten leaves after the greening treatment;

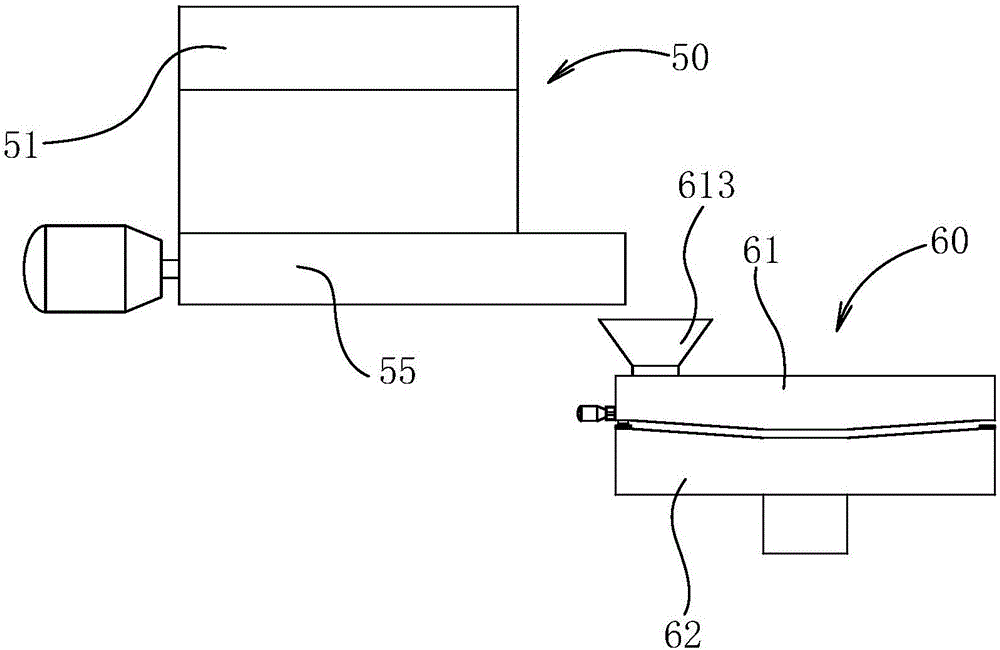

[0057] S4: sending the revived bean curd leaves to the bean curd leaf pulping system for impurity removal and refinement treatment to obtain bean curd pulp;

[0058] S5: Add brine to the bean curd slurry, mix well, and then let it stand to condense to prepare the bean curd tofu.

[0059] Further options are:

[0060] In step S1, the rotten maiden leaves are spread for 2 to 8 hours, preferably 3 hours, at which time the smell of green grass is gone, and the aroma is basically released.

[0061] Rotten leaves are different from ordinary plant leaves. The leaves are thin and one-sided ...

Embodiment 1

[0101] Send the picked bean curd fresh leaves to the bean curd leaf pulping system for impurity removal and refinement treatment to obtain a bean curd pulp, and add 4 to 6 times the weight of water to the bean curd leaves for pulping; to the prepared bean curd leaves Add brine to the slurry, mix it and let it stand for coagulation to make curd tofu. The brine is prepared from plant ash and water, and 1 to 2 parts by weight of brine is added to every 100 parts by weight of bean curd pulp for mixing.

[0102] The above-mentioned curd maid bean curd made, its mouthfeel is relatively poor (sand is greasy), the color is darker dark green, the dehydration rate of curd maid bean curd is higher.

Embodiment 2

[0104] Put the fresh pickled bean curd leaves on the bamboo mat and spread them naturally for 2-8 hours; microwave the green bean curd leaves that are naturally spread, control the power of microwave deenzyming to 1-2kw, and the time for microwave deenzyming to be 120-150s ; Cool the bean curd leaves after the greening treatment for 20 to 30 minutes; send the revived bean curd leaves to the bean curd leaf pulping system for impurity removal and refinement treatment to obtain a bean curd pulp, the bean curd leaves Add 4 to 6 times the weight of water to the leaves for pulping; add brine to the prepared bean curd slurry, mix evenly and leave it to condense to obtain the bean curd bean curd. The bittern is prepared from 1.8 parts by weight of calcium carbonate, 0.3 parts by weight of potassium bicarbonate and 8 parts by weight of water; 1-2 parts by weight of bittern is added to every 100 parts by weight of bean curd slurry for mixing.

[0105] The above-mentioned made curd tofu ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com