Classification device of metal powder and using method

A metal powder and classification device technology, applied in the fields of metal powder classification device and fine metal powder classification device, can solve the problems of easy clogging of the screen, light specific gravity of the fine powder, difficult screen classification, etc., to ensure the purity, The effect of improving quality and high grading accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

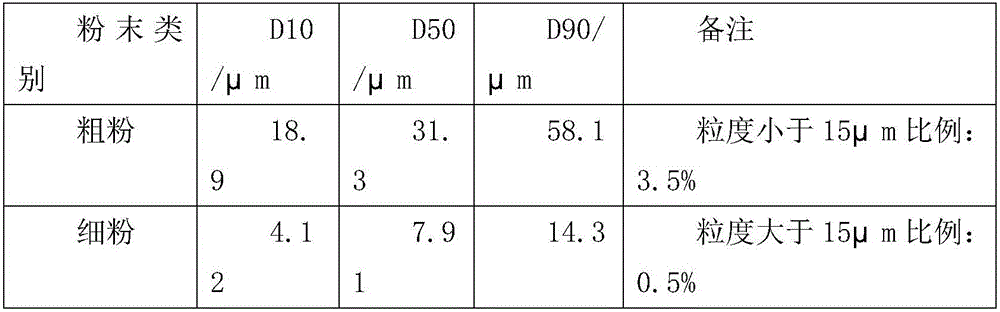

Embodiment 1

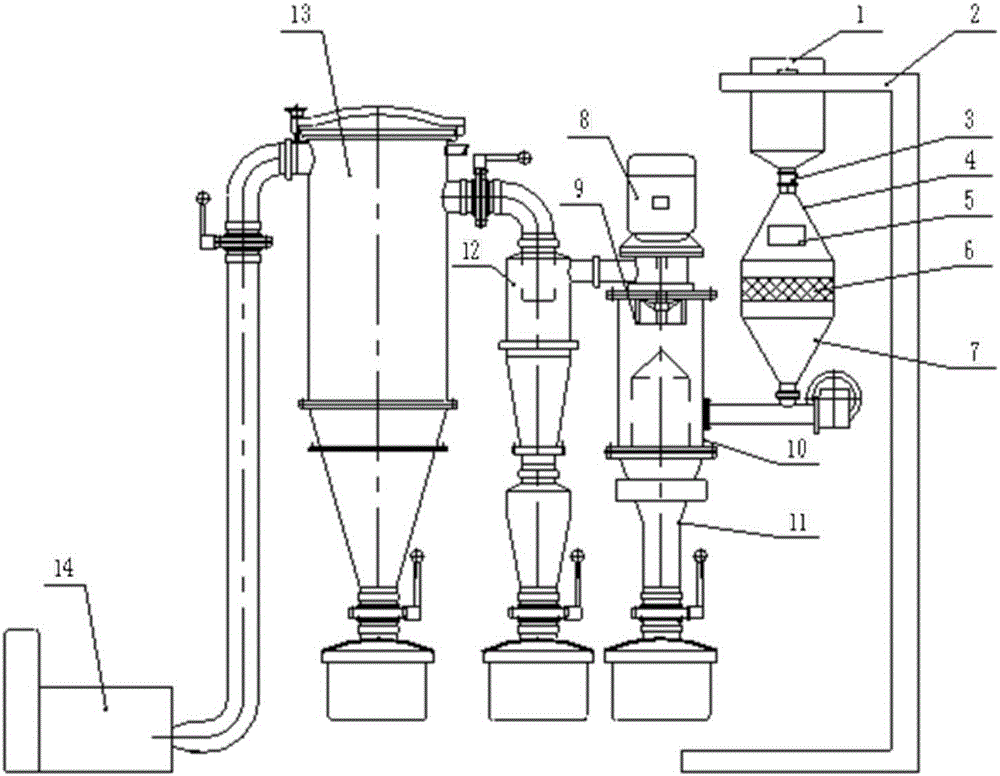

[0023] 1. Take 5Kg superalloy powder, brand GH3536, particle size 0-53μm, put the powder into the powder storage tank in a vacuum glove box, and close the ball valve.

[0024] 2. Put the powder storage tank with the powder upside down on the bracket.

[0025] 3. The lower end of the ball valve is connected to a stainless steel hose, the length of the hose is 200mm, and the lower end of the hose is connected to a KF40-80 adapter.

[0026] 4. The lower end of the adapter is connected to the upper cover of the inlet, and the upper cover of the feed inlet and the feeding funnel are connected through a cylindrical dust filter tube.

[0027] 5. Turn on the inverter switch of the classifier, and run the empty car at a low speed of 9Hz for 15 minutes. Start the induced draft fan, the power of the induced draft fan is 3KW, after the fan is running in balance, open the damper of the induced draft fan and the secondary air valve, the damper of the induced draft fan is fully opened, and ...

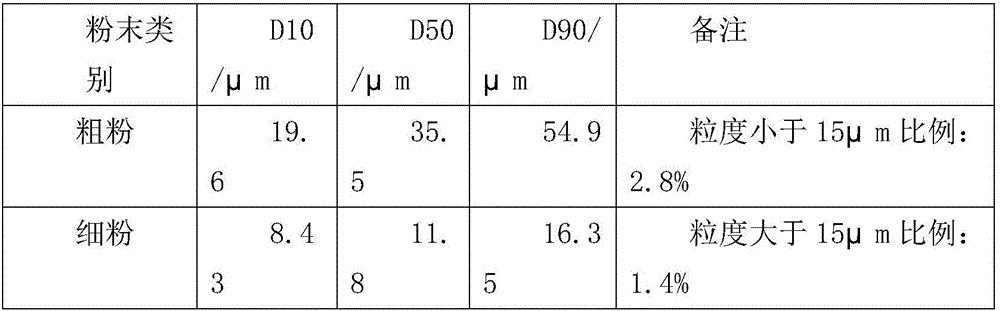

Embodiment 2

[0034] 1. Take 5Kg of titanium alloy powder, brand TC4, particle size 0-53μm, put the powder into the powder storage tank in a vacuum glove box, and close the ball valve.

[0035] 2. Put the powder storage tank with the powder upside down on the bracket.

[0036] 3. The lower end of the ball valve is connected to a stainless steel hose, the length of the hose is 240mm, and the lower end of the hose is connected to a KF40-80 adapter.

[0037] 4. The lower end of the adapter is connected to the upper cover of the inlet, and the upper cover of the feed inlet and the feeding funnel are connected through a cylindrical dust filter tank.

[0038] 5. Turn on the inverter switch of the classifier, and run the empty car at a low speed of 9Hz for 15 minutes. Start the induced draft fan, the power of the induced draft fan is 3KW, after the fan is running in balance, open the damper of the induced draft fan and the secondary air valve, the damper of the induced draft fan is fully opened, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com