Mold pressing device for preparing PVC blocky mold-pressed floor board and preparation method thereof

A molding and flooring technology, which is applied to flat products, other household appliances, household components, etc., can solve the problems of not being beautiful and elegant, difficult to cut materials, and easy to have seams, etc., to achieve realistic real wood paving effects, reduce production costs, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

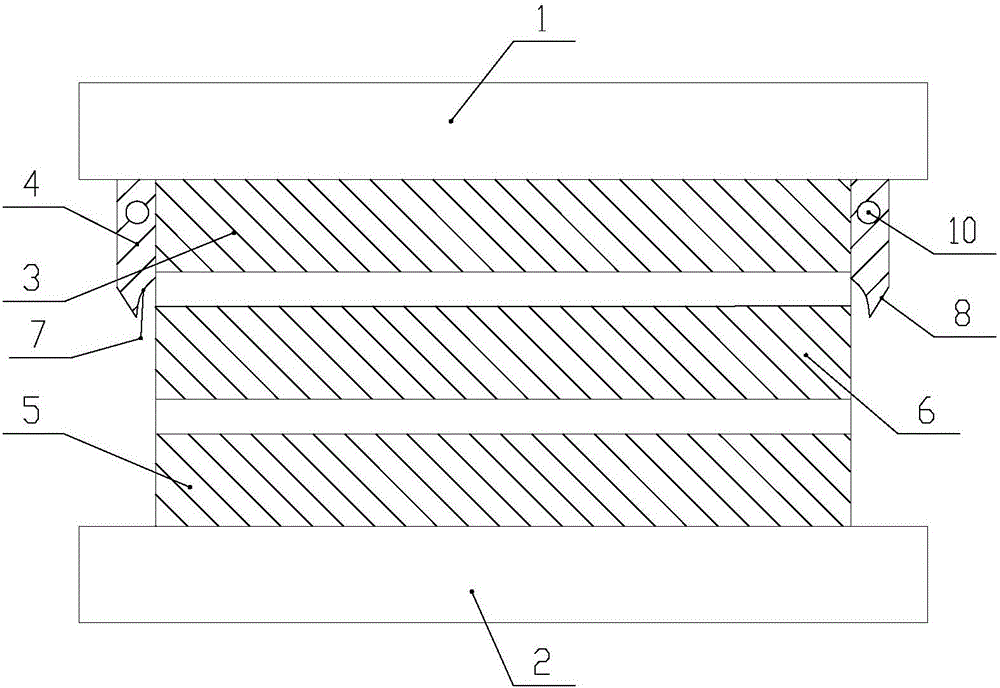

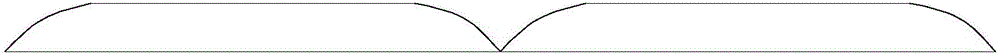

[0058] A molding device for preparing PVC block molded flooring, including a fixed template 1 and a movable template 2 facing up and down, and an upper module 3 and knives symmetrically distributed on both sides of the upper module 3 are fixedly connected to the lower part of the fixed template 1 4. The first blade 7 on the cutter 4 close to the upper module 3 is an arc-shaped blade for cutting the side of the floor to form a circular arc chamfer; the upper part of the movable template 2 is fixedly connected with the lower module 5, the A discharge block 6 is provided between the lower module 5 and the upper module 3; the plate to be molded is placed in the discharge block 6, and the hot pressing is realized through the upper module 3 and the lower module 5, and the cutter 4 cuts the plate to form PVC block molded flooring. The second cutting edge 8 on the cutter 4 away from the upper module 3 is a beveled cutting edge, and the included angle between the second cutting edge 8 ...

Embodiment 2

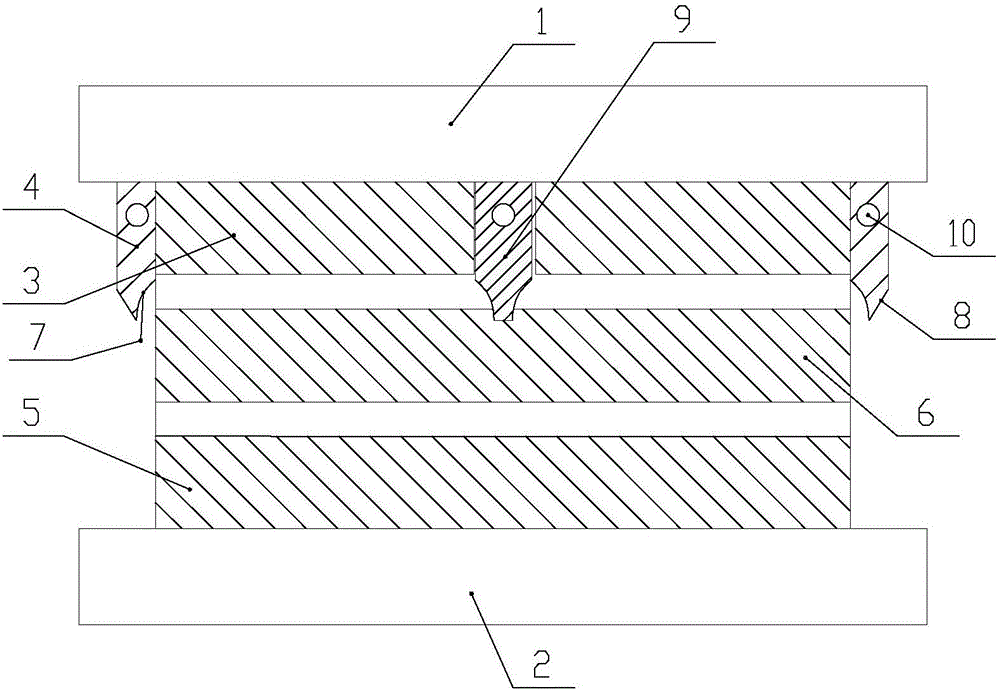

[0066] The embossing device is the same as in Embodiment 1, except that at least one double-edged cutter 9 is provided under the fixed template 1 between the two-side cutters 4, and the double-edged cutter 9 has two blades for the floor. Side cutting with a curved edge that forms a rounded chamfer. The cutting tool and the double-edged cutting tool of the present invention are provided with a heating device for heating the cutting tool, the heating temperature is 100°C, and the heating time is 8s.

[0067] Hot pressing:

[0068] (1) Prepare materials: prepare the negative film, color film and wear-resistant layer to be pressed;

[0069] (2) Stacking: When stacking, each layer of material is placed in the middle of the tray and the layers are aligned, no stacking, no stacking, no foreign matter mixed in, no wrinkling of the color film;

[0070] (3) Push into the molding device for hot pressing. The hot pressing temperature is 140°C, the time is 18 minutes, and the pressure is...

Embodiment 3

[0073] The molding device is the same as that in Example 1, except that: the tool of the present invention is provided with a heating device for heating the tool, the heating temperature is 90° C., and the heating time is 6 s.

[0074] Hot pressing:

[0075] (1) Prepare materials: prepare the negative film, color film and wear-resistant layer to be pressed;

[0076] (2) Stacking: When stacking, each layer of material is placed in the middle of the tray and the layers are aligned, no stacking, no stacking, no foreign matter mixed in, no wrinkling of the color film;

[0077] (3) Push into the molding device and carry out hot pressing. The hot pressing temperature is 130°C, the time is 16min, and the pressure is 6mpa; during the hot pressing process, a heating device is set on the knife and / or double-edged knife to heat the knife, and the knife cuts the floor to form a single block And / or multiple floors with curved chamfers, keep the heat and pressure on the floor for 15s at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com