A carbon fiber composite material handbrake cable and preparation method thereof

A composite material and carbon fiber technology, applied in the field of auto parts, can solve problems such as non-recoverability, performance reduction, and plastic deformation of steel wires, and achieve the effects of improving the overall stress state, enhancing strength utilization, and not being easily plastically deformed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

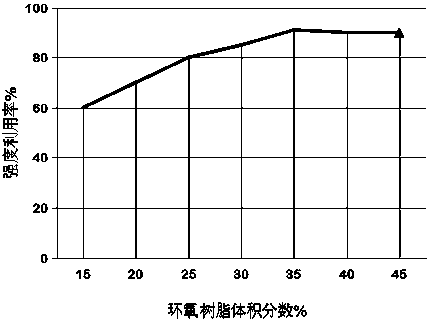

[0016] Raw materials: carbon fiber reinforced material (T700SC-12K) with a volume ratio of 56%, epoxy resin (E44) with a volume ratio of 40%, dimethylaminopropylamine (DEAPA) with a volume ratio of 2%, and a volume ratio of 1% Tri-tertiary aminophenol (DMP-30) and carboxyl-terminated hyperbranched polyester (HBP-SA) with a volume ratio of 1%.

[0017] Specific preparation method:

[0018] (1) Mix the raw materials according to the above volume ratio, so that the resin is firmly combined with the carbon fiber through the impregnation and pre-curing process to form a carbon fiber tow;

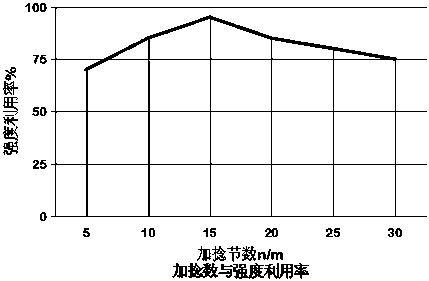

[0019] (2) Braiding the carbon fiber tow in step (1) into a rope by using the rope weaving method to form a twisted cable;

[0020] (3) Put the twisted cable into the curing furnace for secondary curing. The temperature of the curing furnace is controlled at 200°C, and the curing time is at least 4 hours;

[0021] (4) Install the twisted cable after secondary curing in step (3) on the yarn carr...

Embodiment 2

[0024] Raw materials: carbon fiber reinforced material (T700SC-12K) with a volume ratio of 61%, epoxy resin (E44) with a volume ratio of 35%, dimethylaminopropylamine (DEAPA) with a volume ratio of 2%, and a volume ratio of 1% Tri-tertiary aminophenol (DMP-30) and carboxyl-terminated hyperbranched polyester (HBP-SA) with a volume ratio of 1%.

[0025] Concrete preparation method: with embodiment 1

Embodiment 3

[0027] Raw materials: carbon fiber reinforced material (T700SC-12K) with a volume ratio of 66%, epoxy resin (E44) with a volume ratio of 30%, dimethylaminopropylamine (DEAPA) with a volume ratio of 2%, and a volume ratio of 1% Tri-tertiary aminophenol (DMP-30) and carboxyl-terminated hyperbranched polyester (HBP-SA) with a volume ratio of 1%.

[0028] Concrete preparation method: with embodiment 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com