Lily tea wine and preparation method thereof

A technology for lily and tea wine, which is applied in the field of wine production, can solve the problems of lily being less in nutrients, less in nutrients, difficult to absorb, etc., and achieve the effects of alleviating browning, low alcohol content, and suitable sugar-acid ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

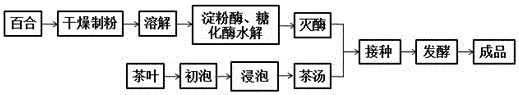

Image

Examples

Embodiment 1

[0024] Embodiment 1: a kind of lily tea wine, is made by lily powder and tealeaves, and the weight ratio of its composition is: lily powder 15g, tealeaves 10g, and it comprises the following steps:

[0025] (1) Making tea soup: Weigh 10g of tea leaves, soak them in 100ml of cold water for 10 minutes, filter the filtrate, and transfer the tea leaves into 600ml of drinking water at a temperature of 90°C. Constant temperature water bath for 10 minutes, filter the tea leaves while hot to make tea soup;

[0026] (2) Production of lily juice: fresh lily lily is dried and powdered to obtain lily powder, which is then liquefied and saccharified to obtain lily juice;

[0027] Weigh 15g of lily powder and dissolve it in 3000ml of boiled drinking water until it dissolves, add 0.06g of amylase, place in a constant temperature water bath at 90°C for 1 hour, cool to below 65°C, adjust the pH to 4.5, and then add 0.05g of glucoamylase , in a constant temperature water bath at 65°C for 1 hou...

Embodiment 2

[0033] Embodiment 2: a kind of lily tea wine, is made by lily powder and tealeaves, and the weight ratio of its composition is: lily powder 14g, tealeaves 9g, and it comprises the following steps:

[0034] (1) Preparation of tea soup: Weigh 14g of tea leaves, soak them in 90ml of cold water for 10 minutes, filter the filtrate, and transfer the tea leaves into 540ml of drinking water at a temperature of 90°C. Put it in a constant temperature water bath for 10 minutes, and filter out the tea leaves while they are hot to make tea soup;

[0035] (2) Production of lily juice: fresh lily lily is dried and powdered to obtain lily powder, which is then liquefied and saccharified to obtain lily juice;

[0036]Weigh 14g of lily powder and dissolve it in 2800ml of boiled drinking water until it dissolves, add 0.056g of amylase, place in a constant temperature water bath at 90°C for 1 hour, cool to below 65°C, adjust the pH to 4.5, and then add 0.05g of glucoamylase , in a constant tempe...

Embodiment 3

[0042] Embodiment 3: a kind of lily tea wine, is made by lily powder and tealeaves, and the weight ratio of its composition is: lily powder 16g, tealeaves 11g, and it comprises the following steps:

[0043] (1) Preparation of tea soup: Weigh 11g of tea leaves, soak them in 110ml of cold water for 10 minutes, filter the filtrate, and transfer the tea leaves into 660ml of drinking water at a temperature of 90°C. Put it in a constant temperature water bath for 10 minutes, and filter out the tea leaves while they are hot to make tea soup;

[0044] (2) Production of lily juice: fresh lily lily is dried and powdered to obtain lily powder, which is then liquefied and saccharified to obtain lily juice;

[0045] Weigh 16g of lily powder and dissolve it in 2800ml of boiled drinking water until it dissolves, add 0.064g of amylase, place in a constant temperature water bath at 90°C for 1 hour, cool to below 65°C, adjust the pH to 4.5, and then add 0.05g of glucoamylase , in a constant te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com