Full-closed coal mining device for soil-like coal working face and coal mining method of full-closed coal mining device

A coal mining device and working face technology, which is applied in ground mining, earth square drilling, mining equipment, etc., can solve the problem that the effect of preventing side and roof fall is not very good, and the safety of coal mining in the working face is not good. No guarantee, safety hazards in production and management of the working face, etc., to achieve the effect of avoiding coal wall fragmentation, improving work safety, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

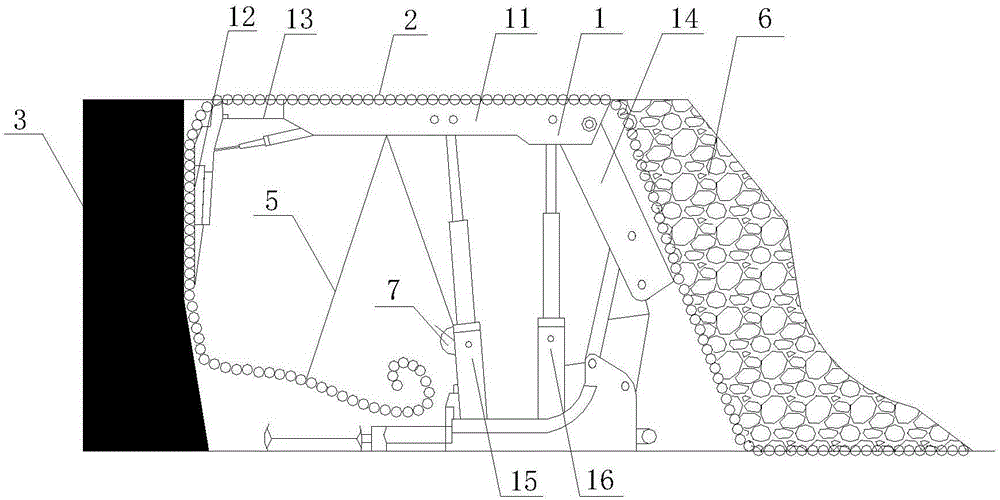

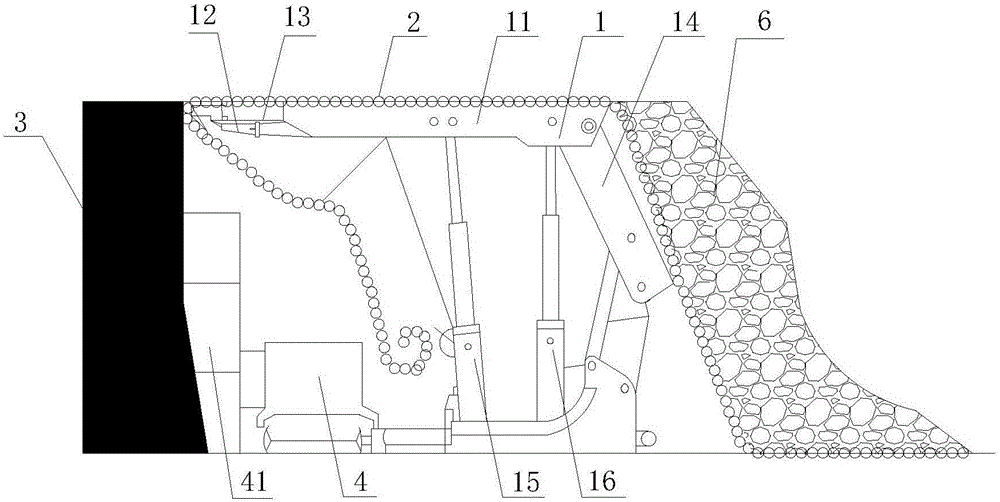

[0024] A fully enclosed coal mining device for earthy coal working faces, including a hydraulic support 1, a carbon fiber mesh 2 and a shearer 4, the carbon fiber mesh 2 is a diamond-shaped carbon fiber mesh, the diameter of the carbon fiber mesh 2 is Φ=0.75mm, and the side length of the rhombus is 2cm. Tensile strength σ of carbon fiber mesh 2 t =2000MPa, ρ=1750kg / m 3 The hydraulic support 1 is a supporting shield type hydraulic support. The hydraulic support 1 includes a top beam 11, a side guard 12, a telescopic beam 13, a cover beam 14, a front column 15 and a rear column 16, and a carbon fiber mesh 2 is laid on the top of the hydraulic support 1. , the rear portion of the shield beam 14 is also covered with carbon fiber mesh 2, and the carbon fiber mesh 2 positioned at the rear portion of the shield beam 14 is laid along the sidewall of the gangue 6, one end of the carbon fiber mesh 2 is fixed on the bottom of the gangue 6, and the carbon fiber mesh 2 The other end hangs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter φ | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com