Coal-fired unit eh oil and steam turbine regulation security system debugging method and system

A technology for security systems and coal-fired units, applied in engine testing, machine/engine, machine/structural component testing, etc., can solve problems such as hidden dangers in the safe operation of steam turbine generator sets, and achieve normal vibration, good insulation, and action flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0144] The present invention will be described in further detail below through examples, and the following examples are explanations of the present invention and the present invention is not limited to the following examples.

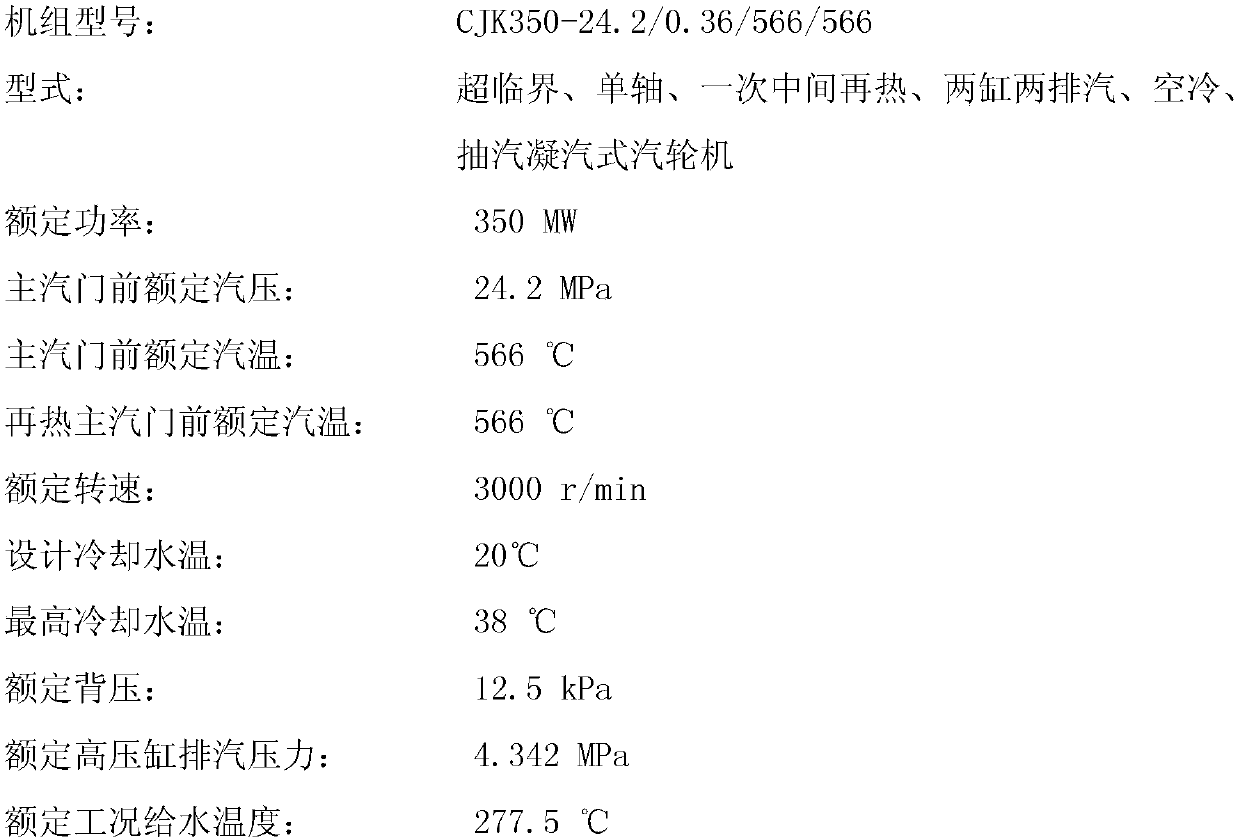

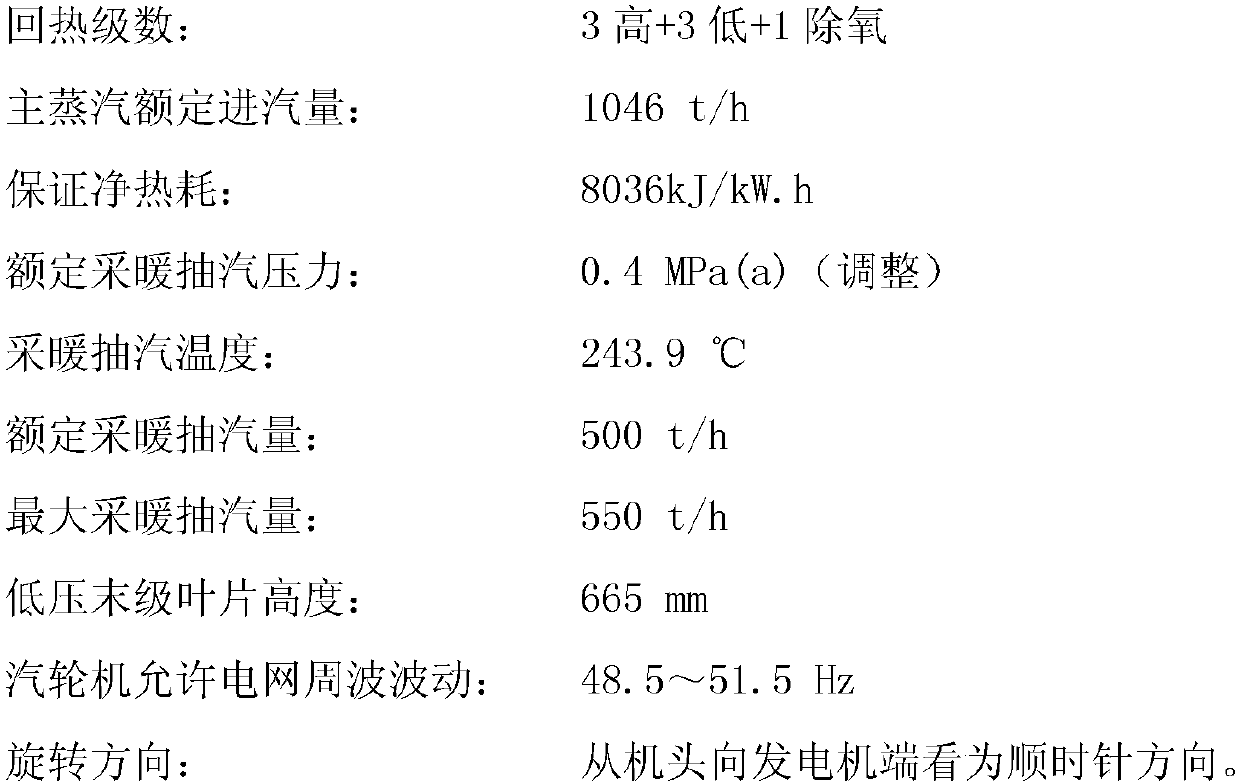

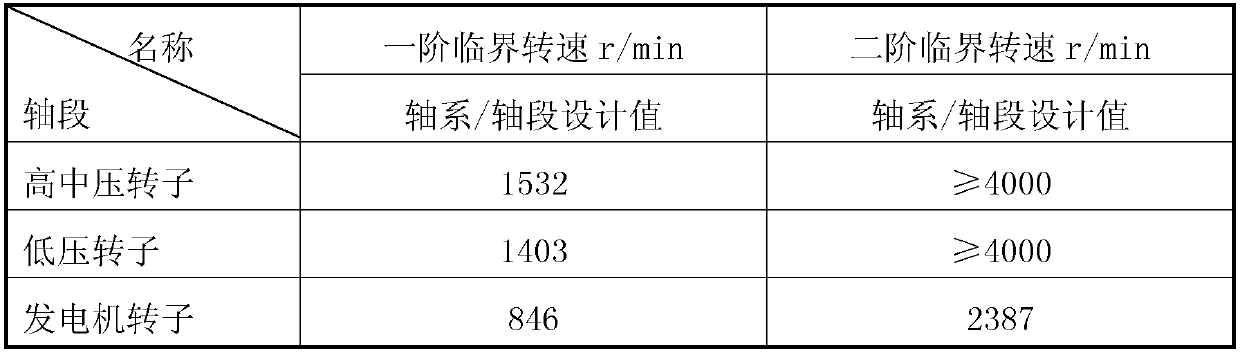

[0145]The invention is suitable for debugging the steam turbine of a coal-fired unit, and the steam turbine is a supercritical, single-shaft, one-time intermediate reheating, two-cylinder, two-exhaust, air-cooled, steam extraction and condensing steam turbine. It is characterized by the use of digital electro-hydraulic adjustment system, easy operation, safe and reliable operation. Provide pressure adjustable heating network extraction, the pressure adjustment range is between 0.245Mpa(a) to 0.6Mpa(a) (when the pressure is lower than 0.36MPa, it is realized by throttling the extraction valve on the extraction pipeline); It can also provide non-adjusted industrial steam extraction with a pressure of about 0.9MPa or 2MPa at the same time. The high and me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com