Enhanced engine valve and manufacturing process thereof

A technology for engine valve and preparation process, which is applied to engine components, machines/engines, mechanical equipment, etc., can solve problems such as difficulty in meeting valve usage requirements, high working temperature of valve cone surfaces, and large working stress, and achieve good product reliability. , Good processing technology, wide application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

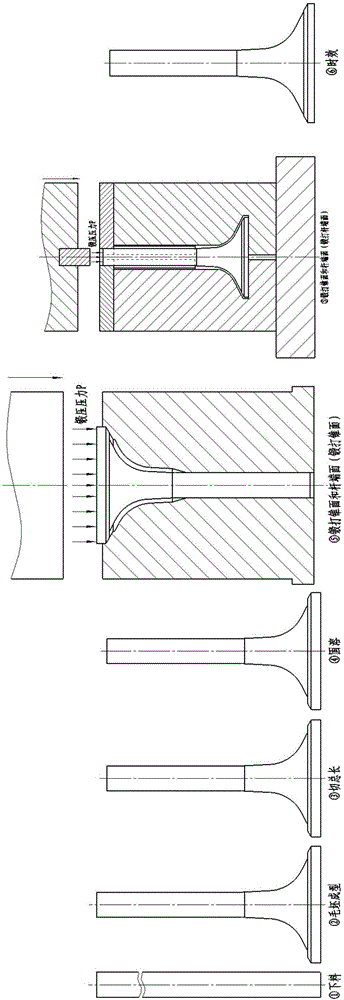

[0032] see image 3 , taking the valve made of GH4080A material in the national standard GB / T12773-2008 "Steel and Alloy Bars for Internal Combustion Engine Valves" as an example, to prepare the reinforced engine valve in this embodiment, the preparation process is as follows:

[0033] In the first step, GH4080A material is used for batching and smelting treatment;

[0034] Step 2, blank forming;

[0035] Step 3, cut the total length to ensure the total length of the valve;

[0036] Step 4, solution treatment, the solution temperature is 1050°C, and the solution time is 1h;

[0037] Step 5, forging the valve cone surface and rod end surface;

[0038] Step 6, aging treatment, the aging temperature is 710°C, and the air cooling time is 16h.

[0039] After the processing of the valve formed by GH4080A material is completed, the hardness of the valve cone surface and the end surface of the rod is 40HRC-48HRC.

Embodiment 2

[0041] see image 3 , taking the NCF3015 material in the valve material national standard GB / T12773-2008 "Steel and Alloy Bars for Internal Combustion Engine Valves" as an example to prepare the reinforced engine valve in this embodiment, the preparation process is as follows:

[0042] The first step is to use NCF3015 material for batching and smelting treatment;

[0043] Step 2, blank forming;

[0044] Step 3, cut the total length to ensure the total length of the valve;

[0045] Step 4, solution treatment, the solution temperature is 1050°C, and the solution time is 0.5h;

[0046] Step 5, forging the cone surface of the valve; Step 6, aging treatment, the aging temperature is 710°C, and the air cooling time is 4h.

[0047] After the processing of the NCF3015 material molded valve is completed, the hardness of the valve cone surface is 44HRC-52HRC.

Embodiment 3

[0049] see Figure 4 , taking the NCF3015 material in the valve material national standard GB / T12773-2008 "Steel and Alloy Bars for Internal Combustion Engine Valves" as an example to prepare the reinforced engine valve in this embodiment, the preparation process is as follows:

[0050] The first step is to use NCF3015 material for batching and smelting treatment (the hardness of the raw material is lower than 30HRC: austenitic materials such as "solid solution state" and "solid solution and semi-solid solution critical state");

[0051] Step 2, blank forming (the valve blank is formed by hot forging, and the hardness of the valve cone surface after hot forging will be lower than that of the raw material before forming);

[0052] Step 3, cut the total length to ensure the total length of the valve;

[0053] Step 4, forging the valve cone surface and rod end surface;

[0054] Step 5, aging treatment, the aging treatment temperature is 750°C, and the air cooling time is 4h.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com